Cost-effective solution for high-quality functional surfaces

When produce interior trims with a modern appearance and cozy texture, Yizumi can provide you with innovative turnkey solution of high-efficiency, high cost effectiveness and high compatibility based on material characteristics and process advantages.

Application Highlights

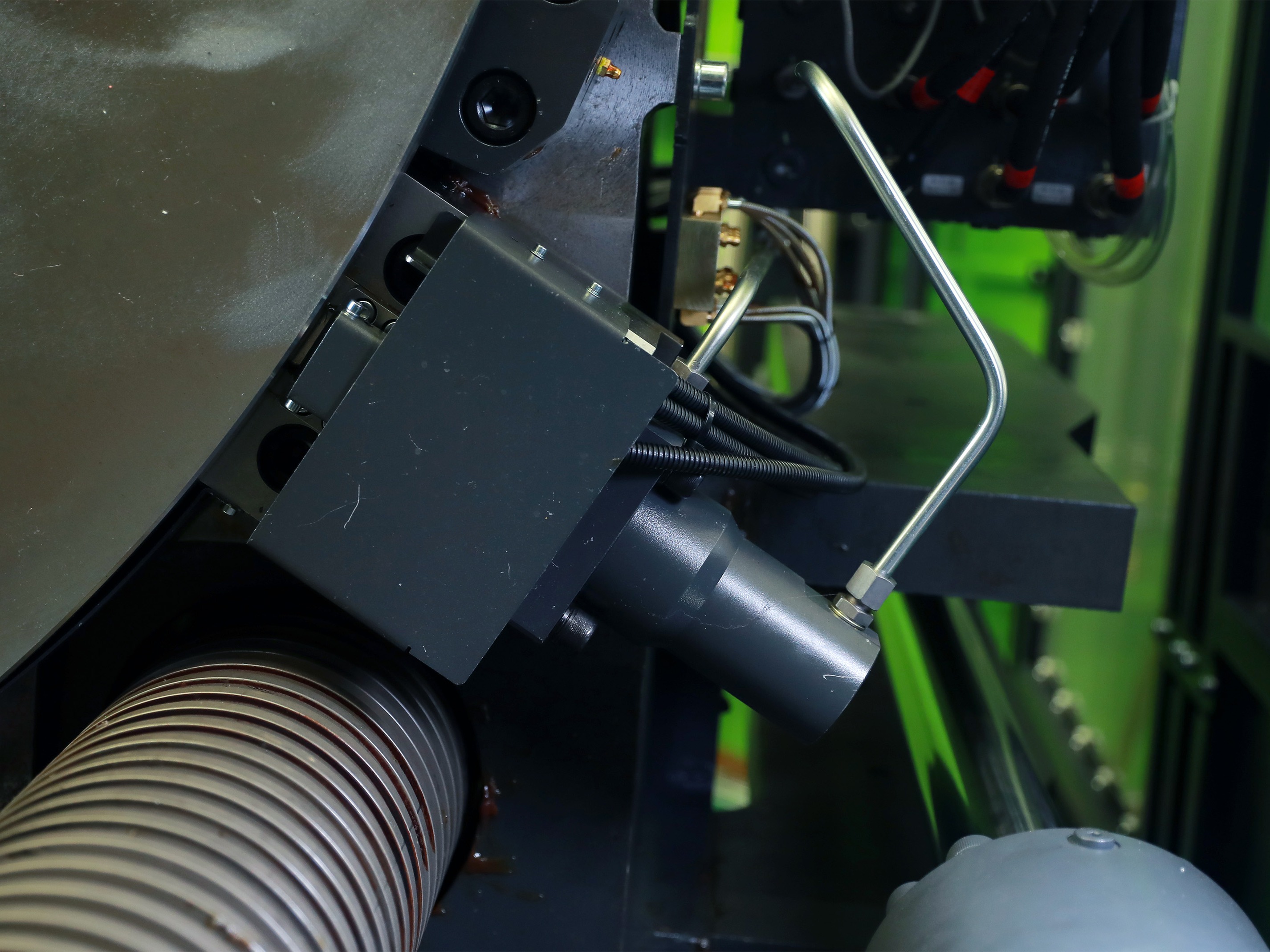

Reliability

Yizumi is your reliable technical collaborator early from the product design.

Innovation

Yizumi achieve product innovation through the application of various techniques and technologies.

Interior Trim Application

Product Video

Relevant Recommendation

Relevant Products

Relevant Technologies

Service Process

01

Process/Mold Analyse and Design

- Raw materials selection

- Product design

- Mold flow analysis

- Mold design suggestion

02

Equipment Selection Suggestions

- Product performance

- Product quality

- Ease of use

- Safety requirements

03

Whole Plant Planning Advice

- Planning of production line

- Arrangements for people, machines, and materials according to process flow

- Peripheral automation

- Smart connection

04

Delivery Solutions

- Professional installation and debugging

- On-site operation training

- Molding process training

05

After Sales Solutions

- YFO services

- Preventive maintenance

- Device upgrade

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.

Application Highlights

Product Video

Relevant Recommendation

Service Process

Contact Us

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.