Value-added Service

Many value-added services and non-profit supports in plant planning, process optimization, molding trial, customer training, technical discussion, industry consultation, energy conservation, and emission reduction can be provided for our overseas customers. Mold trial services can be provided at our Chinese headquarters and all overseas subsidiaries. As we are committed to the research and development of reducing the energy consumption of injection molding machines, our third-generation hydraulic servo system and FF all-electric motor configured in our hydraulic injection molding machines can effectively reduce the energy consumption and meet the national consumption standard I.

Personalization

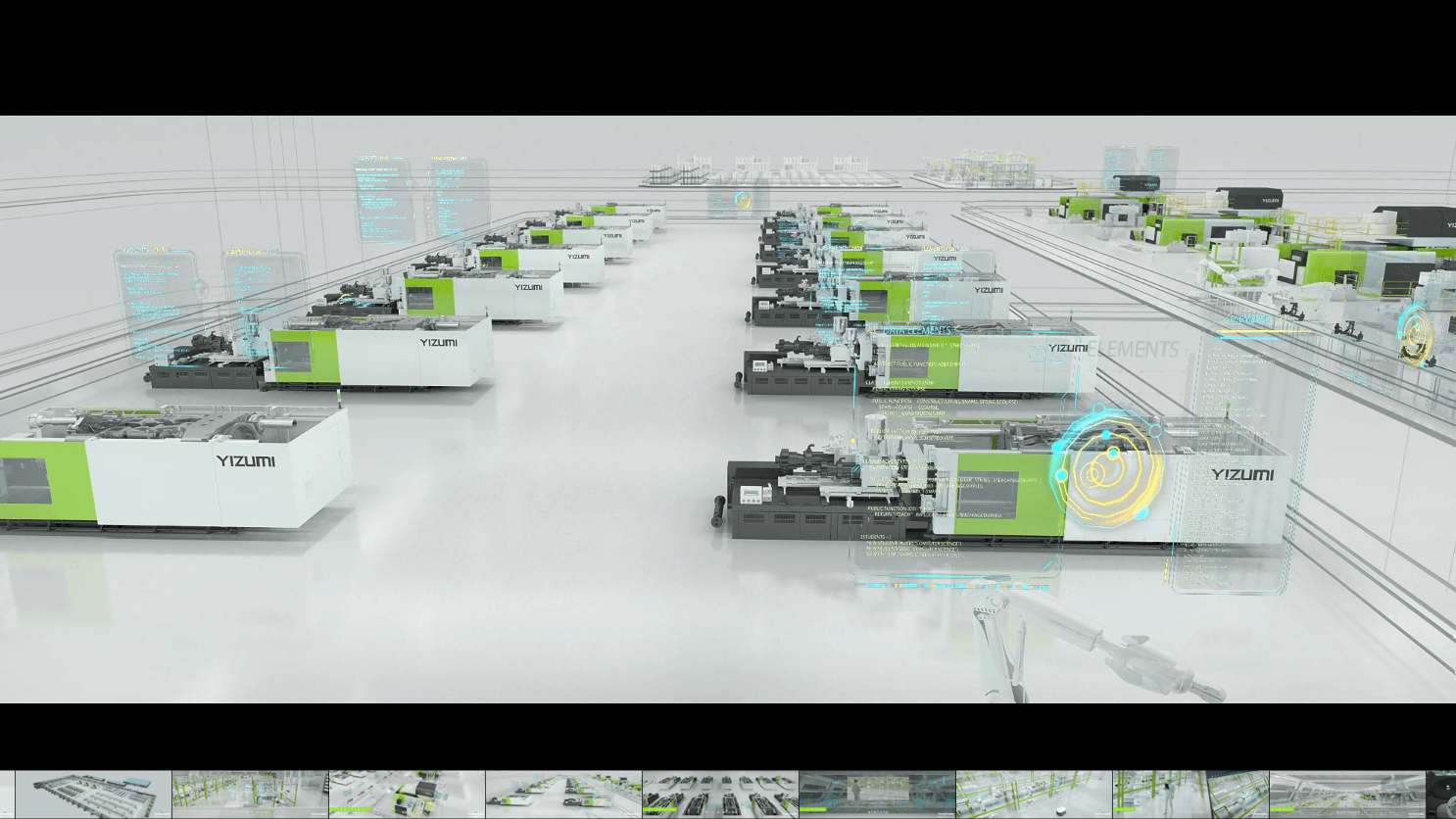

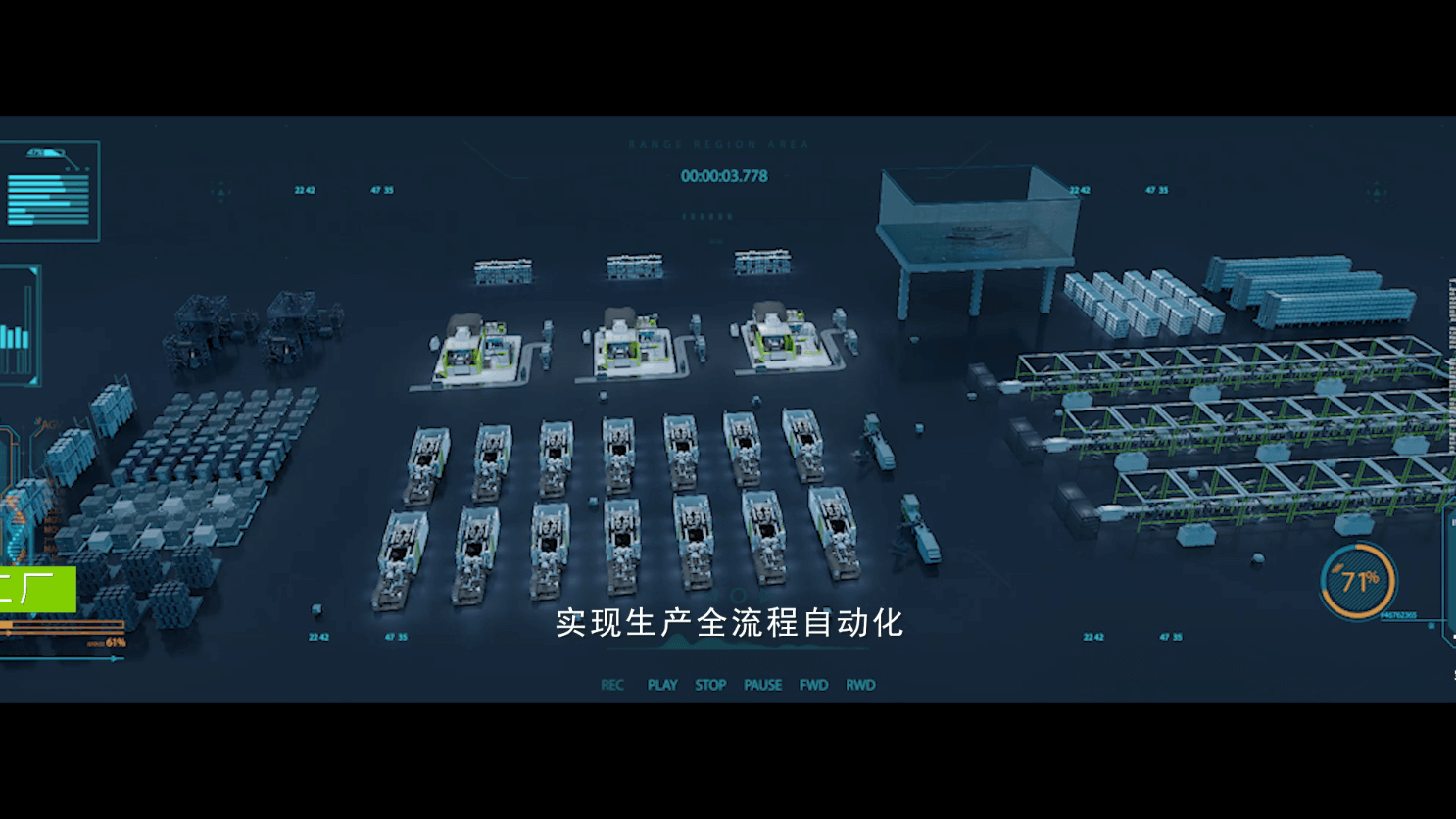

We, YIZUMI devoted to providing the most cost-effective custom solutions to meet our customers' demands for diverse and personalized molding and equipment management through offering more than 800 non-standard configurations, functions, technologies, services, and process control, including back reflection, micro foam, chemical foam, PU molding, silicone molding process scheme for the non-standard equipment, gas planning support, support for whole plant planning, production management system, MES system, OPC/RS232, and other type of solutions to meet our customers' demands for diverse and personalized molding and equipment management.

7/16

Full-time services of 7 days a week and continuous online support of 16 hours a day are offered by our overseas service team of injection molding, including new machine installation and commissioning guidance, maintenance guidance, pre-sales technical support, as well as problem analyses and solutions, to provide fast and effective online and on-site service response and support for the regional customers of our service teams of overseas subsidiaries.

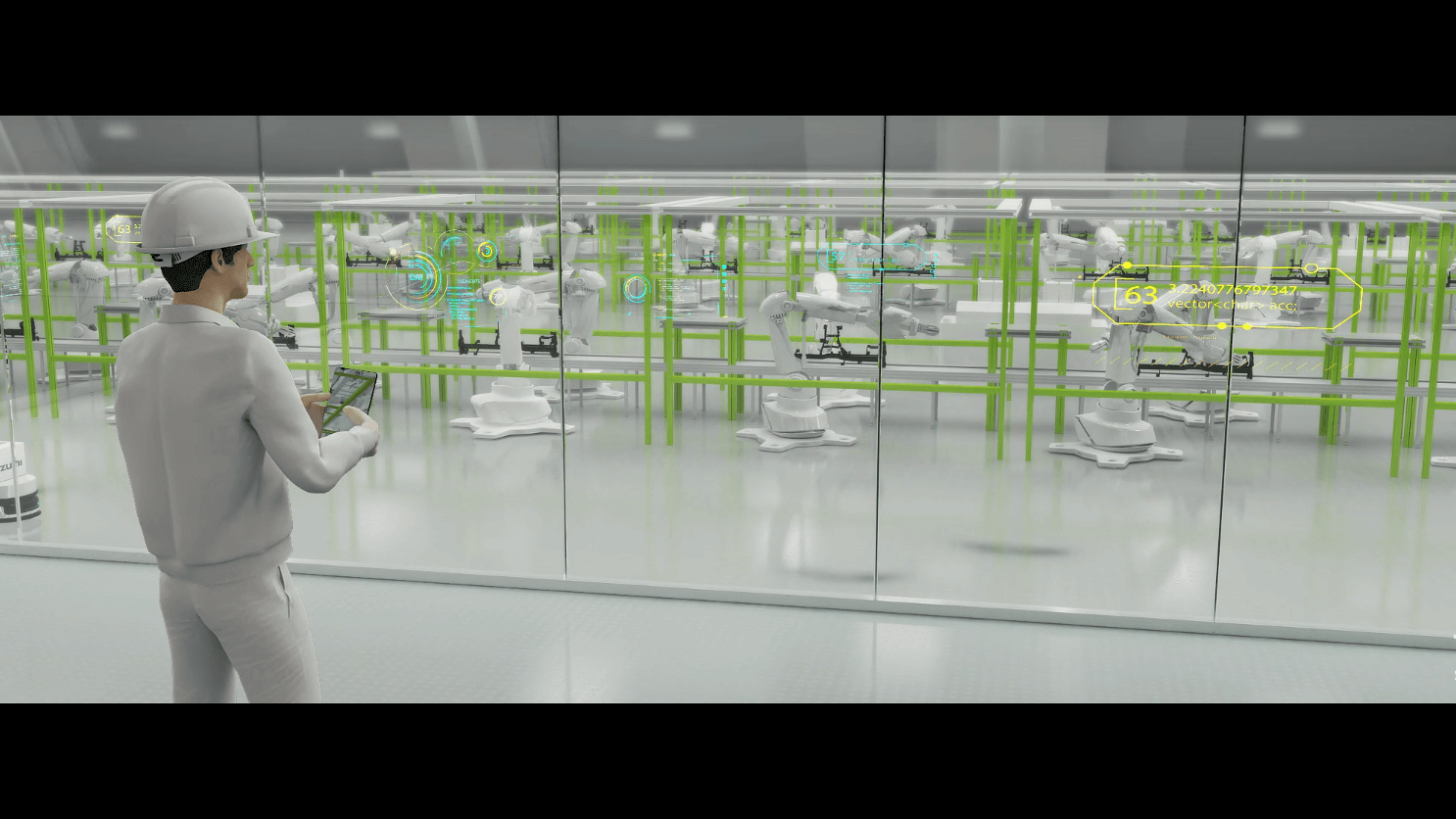

E-Connection

Included 2 tool platforms, the YIZUMI E-connection system could provide timely and effective online support for our customers.

KEBA computer remote diagnosis system: With this system, our service and technical personnel can directly connect the faulty machine's control system to quickly analyze, identify, and solve various problems of it, reduce the downtime of customers, and improve the service efficiency.

AR remote collaboration platform: Through this platform, our experts can provide customers with problem analysis and diagnosis, free the hands of our service personnel, make instant calls, synchronize audio and video, realize real-time technical data sharing, and improve efficiency.

Maintenance System

YIZUMI provides regular maintenance reminding and core component preventive monitoring functions to reduce the risk of equipment failure and prolong its service life. The regular maintenance reminding function can remind customers to maintain their equipment in its whole life cycle and provide online document guidance and maintenance knowledge. The core component preventive monitoring function can efficiently utilize and systematically analyze the information obtained through various sensors to provide customers with predictive maintenance reminders, allowing them to have sufficient time to deal with their spare parts.

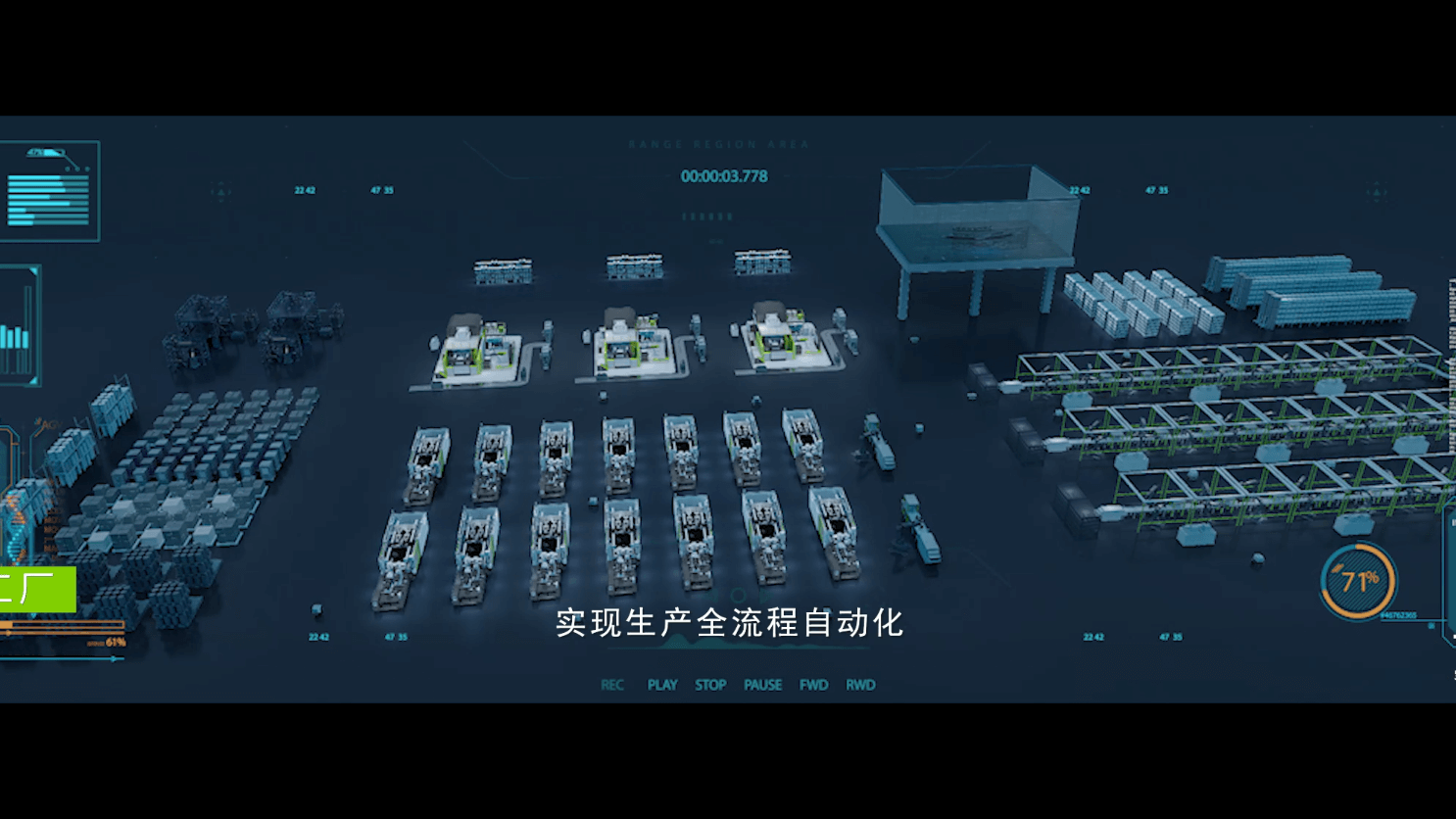

Global Delivery

Our after-sales accessory warehouses are deployed in China headquarters, India, Vietnam, Brazil, the United States, Germany, Israel, France, Malaysia, Indonesia, the Philippines, Colombia, and Mexico, covering hydraulic parts such as servo systems, electrical components such as control systems, processing pieces such as screw & barrel units and wearing parts, all of which can be quickly delivered within 24 hours, to provide fast accessory supports for our global customers.

Upgrading and Reconstruction

The upgrading and reconstruction services for different machines after delivery are provided by YIZUMI, including the program upgrading of special molds and processes, the addition of various realizable customized configurations and functional transformation after delivery, the upgrading and reconstruction of hydraulic servo system, the establishment of the production management system of old equipment, and the upgrading of OPC communication.

Expert Support

Our overseas service team of injection molding machine can provide various training services for customers, including the on-site and online training for new equipment operation, repair and maintenance, and safety operation.

Through ZOOM, the real-time online training for machine operation, repair and maintenance, safety, troubleshooting, special process, equipment selection, peripheral equipment, and new products of injection molding machines can all be provided. In our Youtube service channel, the videos for regular operations and troubleshooting are shared with customers. In addition, we also provide our customers with AR Remote training to create an immersive training experience as if in real-world training scenarios, and all training materials are shared on our cloud storage disks for agents and customers to learn and review.

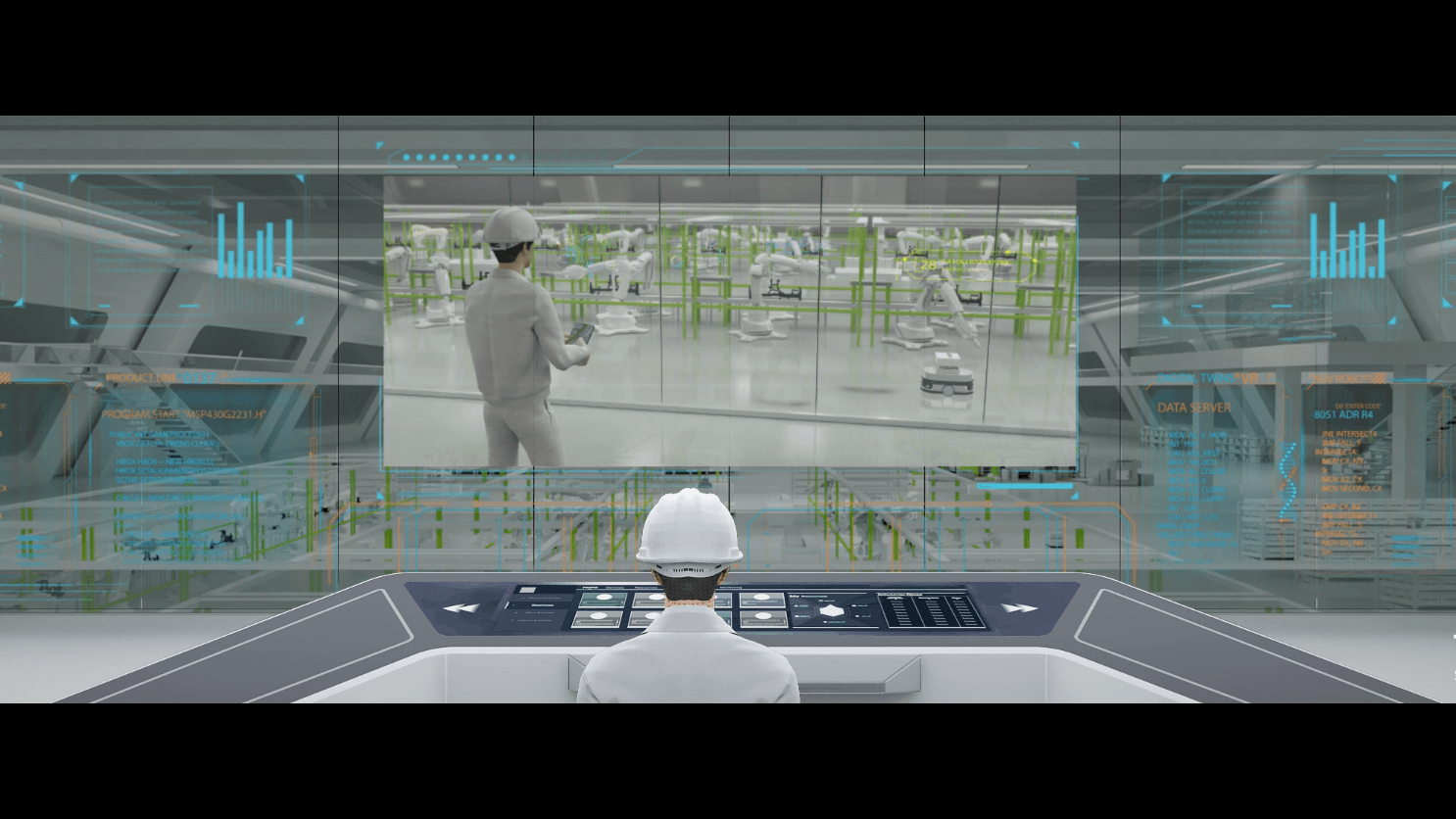

Full Life Cycle Management

The full life cycle management of single injection molding machines has been gradually established in YIZUMI. Through PLM, SAP, and CRM systems, the system support and record of the whole process from contract signing to after-sales services can be realized. For each machine produced, it is configured with one manual, which includes general operating instructions, servo system instructions, control system instructions, as well as control program and SBOM list, to help customers fully understand all information and data on their purchased machines and feel satisfied with their choices.

Personalization

We, YIZUMI devoted to providing the most cost-effective custom solutions to meet our customers’ demands for diverse and personalized molding and equipment management through offering more than 800 kinds of non-standard configurations, functions, processes, services, and program controls. Meanwhile, we also provide workshop plant planning, equipment configuration scheme, product process scheme, enterprise financing scheme, and product solutions with the best cost performance to better satisfy our clients’ requirements.

7/24

24/365 hotline is available. Over 100 maintenance experts around the world are ready to resolve over 96% of fault problems reported by customer. YIZUMI has established a CRM system service sector, to bring customers a one-stop service experience. From repair report to instant response and on-site repair services, the whole process can be checked by customers in real time (Die Casting).

E-Connection

Included 2 tool platforms, the YIZUMI E-connection system could provide timely and effective online support for our customers.

With remote diagnosis system, our service and technical personnel can directly connect the faulty machine’s control system to quickly analyze, identify, and solve various problems of it, reduce the downtime of customers, and improve the service efficiency.

Through AR remote collaboration platform, our experts can provide customers with problem analysis and diagnosis, free the hands of our service personnel, make instant calls, synchronize audio and video, realize real-time technical data sharing, and improve efficiency.

Maintenance

Regular maintenance reminding and core component preventive monitoring functions are provided by us to reduce the risk of equipment failure and prolong its service life. The regular maintenance reminding function can remind customers to maintain their equipment in its whole life cycle and provide online document guidance and maintenance knowledge. The core component preventive monitoring function can efficiently utilize and systematically analyze the information obtained through various sensors to provide customers with predictive maintenance reminders, allowing them to have sufficient time to deal with their spare parts. In addition, we also pioneer the first maintenance service, providing preventive maintenance service to our customers.

Global Delivery

Country-wide network of service outlets and accessory centers

20 outlet warehouses - a YFO service network covering 76 urban areas in China.

More than 1000 sqm. - 2 accessory center warehouses respectively covering more than 500 sqm. in Wujiang and Shunde.

All-year-round delivery - personnel on duty in accessory center warehouses for delivery throughout the year.

Over 95% local ex-warehouse rate on the same day.

Upgrading and Reconstruction

The upgrading and reconstruction services for different machines after delivery are provided by YIZUMI, including the program upgrading of special molds and processes, the addition of various realizable customized configurations and functional transformation after delivery, the upgrading and reconstruction of the hydraulic servo system, the establishment of the production management system of old equipment, the retrospect and upgrade of product data, and the relocation and commissioning of factory buildings, etc.

Expert Support

To meet customers’ needs for the knowledge of equipment structure and principle, process and product, repair and maintenance, as well as safe operation, and to provide a full range of online and offline diversified training services for customers in need, we have independently developed and established the most professional online system in the die casting industry. It supports 4 languages (Chinese, English, Portuguese, and Russian) and is compatible with PC and Android. This knowledge base platform integrates service and technical documents as well as many maintenance cases related to the die-casting machines of YIZUMI, can reduce the time for maintenance personnel to find technical documents, and can also provide sharing functions.

Full Life Cycle Management

The full life cycle management of a single injection molding machine has been established in YIZUMI. Through PLM, SAP, and CRM systems, the system support and record of the whole process from contract signing to after-sales services can be realized. For each machine produced, it is configured with one manual, which includes general operating instructions, servo system instructions, control system instructions, as well as a control program and SBOM list, to help customers fully understand all information and data on their purchased machines and feel satisfied with their choices.

Value-added Service

Many value-added services and non-profit supports in plant planning, process optimization, molding trial, customer training, technical discussion, industry consultation, energy conservation, and emission reduction can be provided for our customers. The Die Casting Product and Process Application Center (PPAC) established through an investment of more than ten million yuan is designed to ensure the R&D of equipment and technology, as well as the extension of new product programs. As we are committed to the research and development of reducing the energy consumption of die casting machines, our hydraulic servo system for die-casting machines can effectively reduce energy consumption and meet the national consumption standard I.

High Quality Overhaul Services

The overhaul department of YIZUMI has always been committed to meeting the needs of customers. In addition to focusing on the maintenance of our die-casting machines, we also pay attention to the maintenance of the die-casting machines from other major brands at home and abroad.

Dedicated Hydraulic Oil Development

To meet different customers’ needs, we have developed different grades of hydraulic oil, and developed the dedicated high-end hydraulic oil of Y2, Y3, and HI together with international premium brands such as Shell, Chevron, and Caltex.