Products

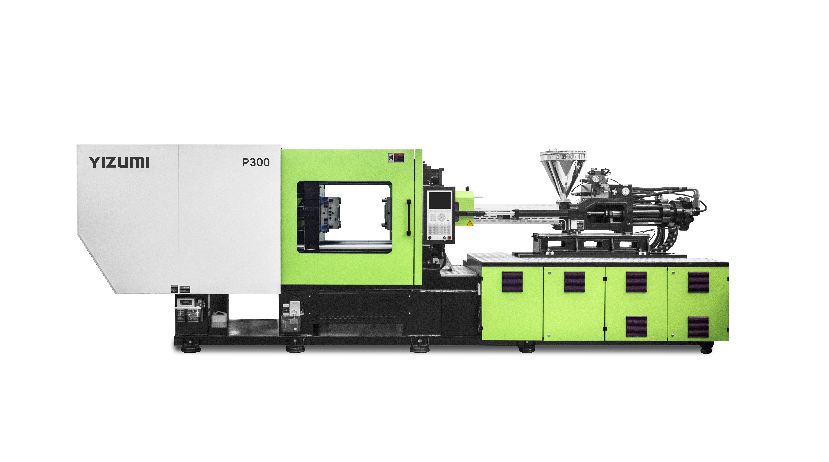

Toggle-clamping Hydraulic Injection Molding Machine

Multi-component Injection Molding Machine

High-speed Injection Molding Machine

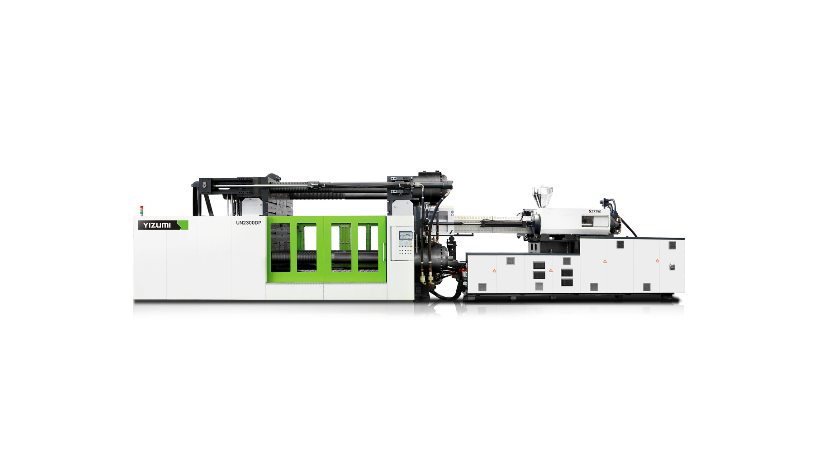

Two-platen Injection Molding Machine

Electric Injection Molding Machine

Special-usage Injection Molding Machine

Vertical Injection Molding Machine

Application

Global Service

Contact Us

Contact us for professional and considerate services.

Contact Us

Media Center

View more

Company News

Latest News

2026-01-28

YIZUMI Global Headquarters Tops Out as a Global Operations Hub

2026-01-01

YIZUMI's New Year Message: Stay Focused and Keep Evolving

2025-12-31

YIZUMI 2025 Highlights: Global Vision, Smart Manufacturing

2026-02-25

Injection Molding Machine Clamping Systems: Toggle vs Two-Platen Compared

In injection molding, the clamping system is one of the most critical components of an injection molding machine. While injection units, control systems, and automation solutions often receive significant attention, the clamping mechanism ultimately determines mold stability, part consistency, machine footprint, and production efficiency.

2026-02-25

Applications of Electric Injection Molding Machines in Medical Manufacturing

The demand for high-quality medical devices and components — including disposable consumables, precision micro-components, and complex polymer parts — continues to rise sharply. This growth has propelled the adoption of advanced manufacturing solutions, particularly electric injection molding machines, which are increasingly recognized as the gold standard for producing high-precision plastic parts in the medical industry.

2026-01-19

YIZUMI & GF Casting Solutions: Power Europe’s Die Casting Future

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.