Standard pneumatic injection nozzle

Water-cooled pneumatic injection nozzle - prevents liquid silicone leakage, and prevents the mold temperature from being transmitted to nozzle and resulting in curing reaction of mixed LSR in the nozzle.

Mixing screw for silicone

- Mixed compounds at the front end of the screw to ensure the fully blending of components A and B while eliminating phenomena such as adhesion, yellowing, or blackening;

- Sensitive seal rings are used as the adaptation to the high liquidity of silicone resin to reduce leakage during injection start-up and injection.

- Sensitive seal rings are used as the adaptation to the high liquidity of silicone resin to reduce leakage during injection start-up and injection.

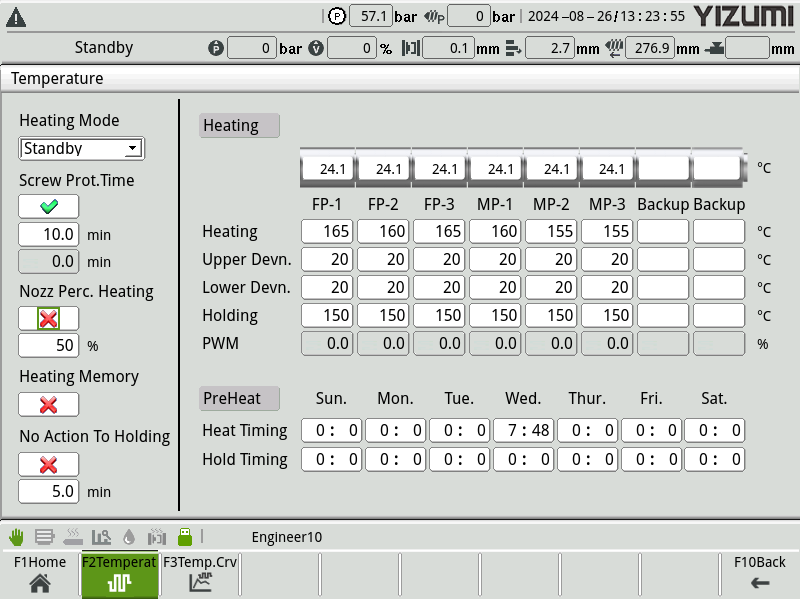

Temperature control for mold heating

- Visualized built-in mold temperature control to facilitate emperature adjusting;

- Separate connecting socket for each set of heating unit for the convenience of customers.

- Separate connecting socket for each set of heating unit for the convenience of customers.

Standard pneumatic 2-piece filter and air gun fittings

User friendly design for easy connection to the air gun and silicone feeder on site

Auxiliary Equipment - YIZUMI liquid silicone feeder

- Fully pneumatic secondary metering system, energy efficient and pollution free;

- Manual correction of A/B material component ratio. Ratio error less than 3%;

- Maintenance free design - silicone leakage free, less waste;

- Uniform color mixing with no flow marks,high repetition accuracy.

- Manual correction of A/B material component ratio. Ratio error less than 3%;

- Maintenance free design - silicone leakage free, less waste;

- Uniform color mixing with no flow marks,high repetition accuracy.

Product Video

Industry Application

Relevant Recommendation

Relevant Products

Relevant Technologies

Service Process

01

Process/Mold Analyse and Design

- Raw materials selection

- Product design

- Mold flow analysis

- Mold design suggestion

02

Equipment Selection Suggestions

- Product performance

- Product quality

- Ease of use

- Safety requirements

03

Whole Plant Planning Advice

- Planning of production line

- Arrangements for people, machines, and materials according to process flow

- Peripheral automation

- Smart connection

04

Delivery Solutions

- Professional installation and debugging

- On-site operation training

- Molding process training

05

After Sales Solutions

- YFO services

- Preventive maintenance

- Device upgrade

Download

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.