Machine Introduction Video

Machine Introduction Video

Clamping Unit

Stable Tie-Bar Free(TBF) structure

- No contact between the platen and the tie bars, and no lubricating oil on the tie bars, avoid contamination to product;

- Low mechanical friction resistance during mold opening and closing, less energy loss;

- Stable and reliable structure.

- Low mechanical friction resistance during mold opening and closing, less energy loss;

- Stable and reliable structure.

Injection pressure closed-loop control

- Make the control more precise and the molding more stable and reliable;

- Stability accuracy of injection pressure and holding pressure up to ± 0.1Mpa.

- Stability accuracy of injection pressure and holding pressure up to ± 0.1Mpa.

Linear guide rail structure

- Guiding accuracy can reach 0.02mm;

- Fast and stable mold opening and closing, with high repeatability up to±0.03mm.

- Fast and stable mold opening and closing, with high repeatability up to±0.03mm.

Injection Unit

High speed injection

Injection speed can reach up to 120-150mm/s for more diversified molding applications so that requirements of commonly used medical products can be met.

High plasticizing efficiency, good plasticizing effect

For raw materials commonly used in medical industry like PP, PS, high-plasticizing and high-mixing screw is used to improve plasticizing efficiency and effect, with over 20% increase when compared with general screw, showing better plasticizing efficiency.

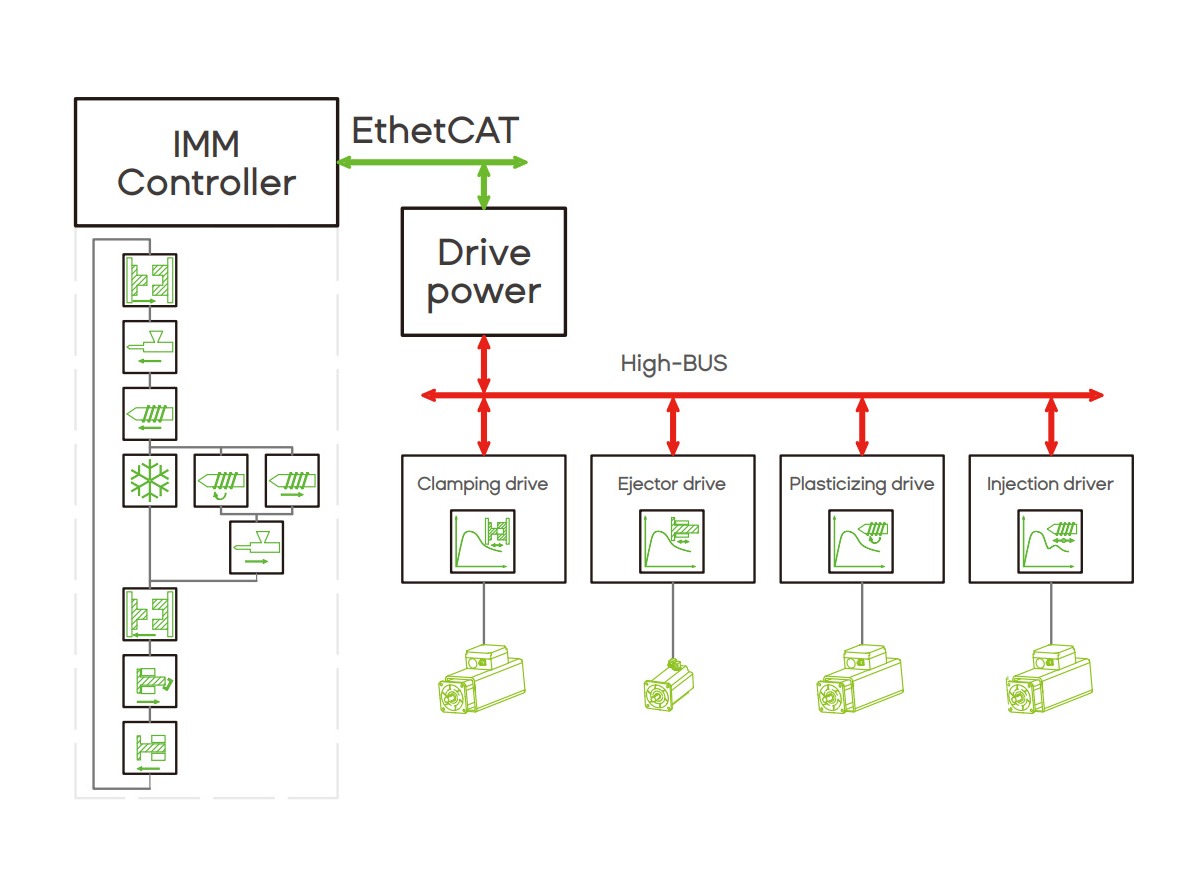

Unique SDC servo direct control technology

- The process algorithm built into the servo driver isindependently developed by YIZUMI;

- Control cycle was reduced from 2-4ms to 0.125ms;

- Injection position, mold opening and closing positionswitching position and control position accuracy aremore accurate.

- Control cycle was reduced from 2-4ms to 0.125ms;

- Injection position, mold opening and closing positionswitching position and control position accuracy aremore accurate.

Intelligent weight control

- Automatic monitoring and real-time dynamic adjustment of molding process parameters;

- Effectively reduce the impact of external factors on the molding process, such as mold temperature, raw material properties, etc., to improve the stability of the process;

- Effectively reduce product weight differences and improve consistency.

- Effectively reduce the impact of external factors on the molding process, such as mold temperature, raw material properties, etc., to improve the stability of the process;

- Effectively reduce product weight differences and improve consistency.

Product Video

Industry Application

Relevant Recommendation

Relevant Products

Relevant Technologies

Relevant Automation

Service Process

01

Process/Mold Analyse and Design

- Raw materials selection

- Product design

- Mold flow analysis

- Mold design suggestion

02

Equipment Selection Suggestions

- Product performance

- Product quality

- Ease of use

- Safety requirements

03

Whole Plant Planning Advice

- Planning of production line

- Arrangements for people, machines, and materials according to process flow

- Peripheral automation

- Smart connection

04

Delivery Solutions

- Professional installation and debugging

- On-site operation training

- Molding process training

05

After Sales Solutions

- YFO services

- Preventive maintenance

- Device upgrade

Download

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.