Machine Introduction Video

Machine Introduction Video

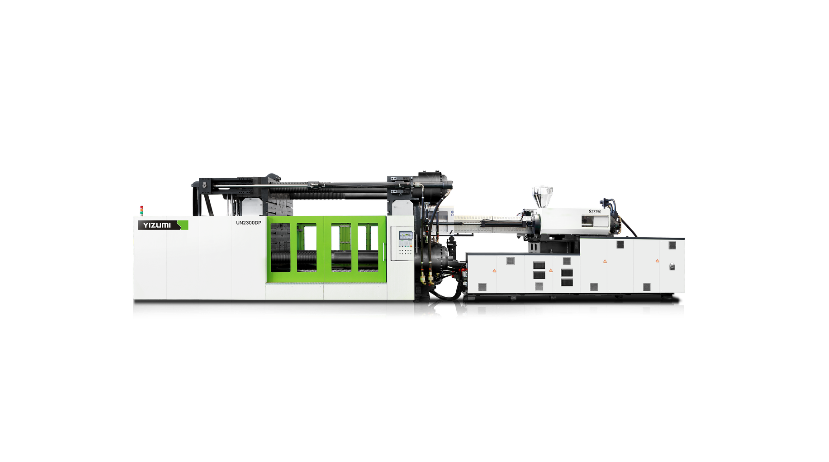

Clamping Unit

Integrated turntable

- Integrated design, high rigidity, large bearing capacity and compact structure;

- The turntable is standard with servo motor with high precision and rotation speed. It can be equipped with multiple groups of water-oil-gas diversion systems at high flow rate.

- The turntable is standard with servo motor with high precision and rotation speed. It can be equipped with multiple groups of water-oil-gas diversion systems at high flow rate.

Digital closed-loop positioning control technology (DCPC)

Turntable driven by servo motor is controlled by DCPC technology, with high rotating speed, smooth operation without impact, accurate positioning and repeatability up to ±0.005°.

Automatic flow-distribution shaft system

Turntable is applied with German automatic flow distribution shaft system, with double layer structure for oil-water separation. It offers centralized management for oil, water and gas. Multi-angle rotary of station is also available by 0° , 90° ,120° , 180° ,240° or 360° , no wear and no tangling for pipeline, wider application.

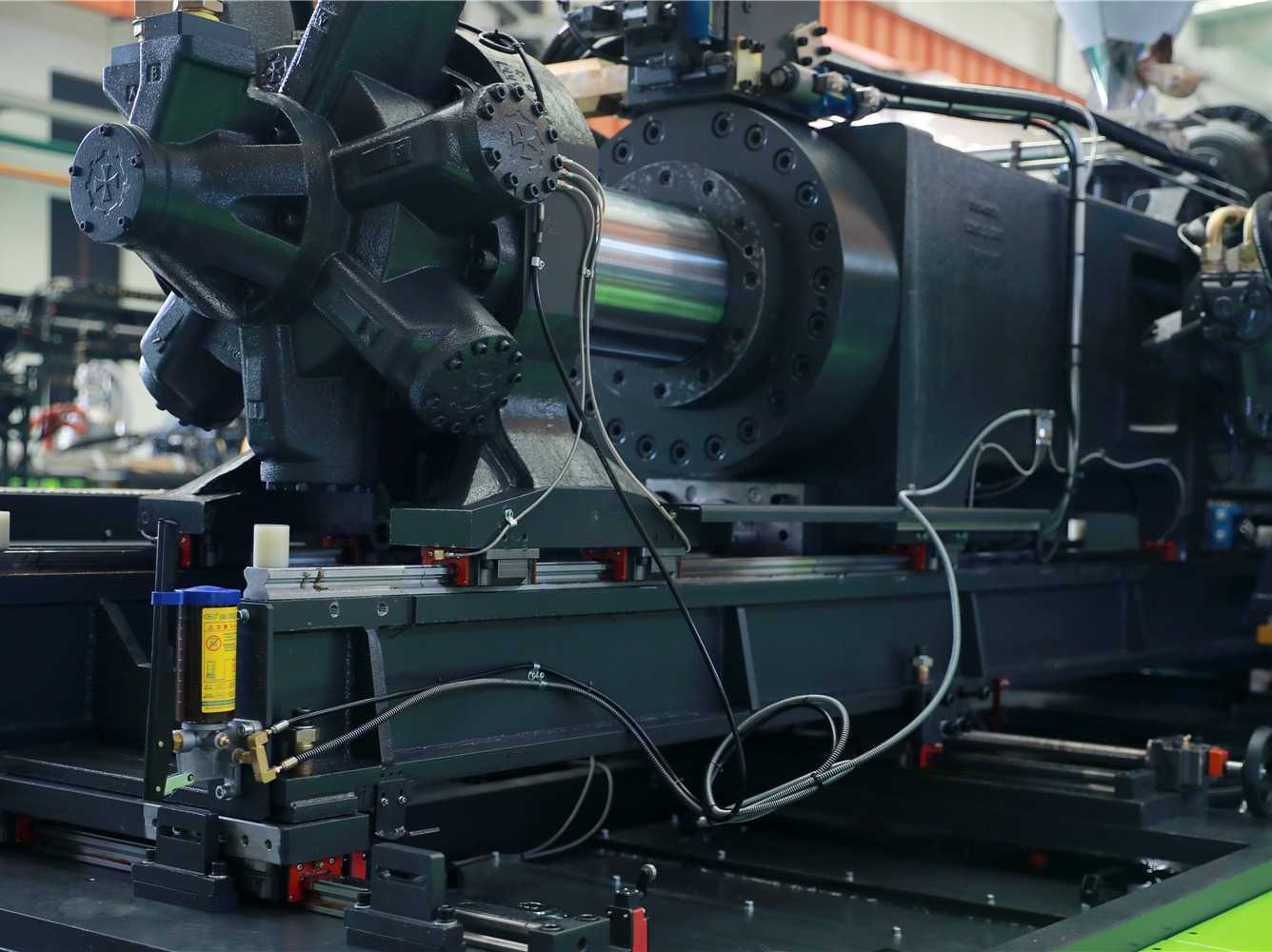

Injection Unit

High injection repeatability

Based on European single-cylinder injection molding technology, it brings low injection inertia and high leak-proof performance of cylinder;

Also combined with high mixing anti-stick screw and precise temperature control, injection stability is further enhanced, making the repeatability of product weight up to 3‰.

Also combined with high mixing anti-stick screw and precise temperature control, injection stability is further enhanced, making the repeatability of product weight up to 3‰.

Proportional valve-controlled back pressure

Precise control to enhance injection stability and provide necessary conditions for excellent plasticizing effect.

New-generation PID temperature control

With adaptive PID temperature control, the static temperature control accuracy reaches up to ±0.5℃

Precise control, reliable and stable, user-friendly design

Austrian KEBA controller is standard for two-platen multi-component injection molding machine. Controller design is reliable, stable, safe and user-friendly, applicable to various multi-component molding solutions, improving customer experience.

Horizontal turntable two-way injection molding

Horizontal turntable is suitable for the molding of long or large two-color products. It can help machine largely reduce clamping force comparing with vertical turntable. Also horizontal turntable can cooperate with the third and the fourth injection units(W type, L type, V type, etc.) in multi-component molding, providing more cost-effective solution.

Product Video

Industry Application

Relevant Recommendation

Relevant Products

Relevant Technologies

Relevant Automation

Service Process

01

Process/Mold Analyse and Design

- Raw materials selection

- Product design

- Mold flow analysis

- Mold design suggestion

02

Equipment Selection Suggestions

- Product performance

- Product quality

- Ease of use

- Safety requirements

03

Whole Plant Planning Advice

- Planning of production line

- Arrangements for people, machines, and materials according to process flow

- Peripheral automation

- Smart connection

04

Delivery Solutions

- Professional installation and debugging

- On-site operation training

- Molding process training

05

After Sales Solutions

- YFO services

- Preventive maintenance

- Device upgrade

Download

Contact Us

Please leave your message, and we will contact you soon!

Salutation *

First name *

Last name *

Phone number *

Country/Region *

Email *

Company *

City

Topic of interest *

Detail request (Subjects / Description / Questions)

Verification code *

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.

Contact Us

Please leave your message, and we will contact you soon!

Salutation *

First name *

Last name *

Phone number *

Country/Region *

Email *

Company *

City

Topic of interest *

Detail request (Subjects / Description / Questions)

Verification code *

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.