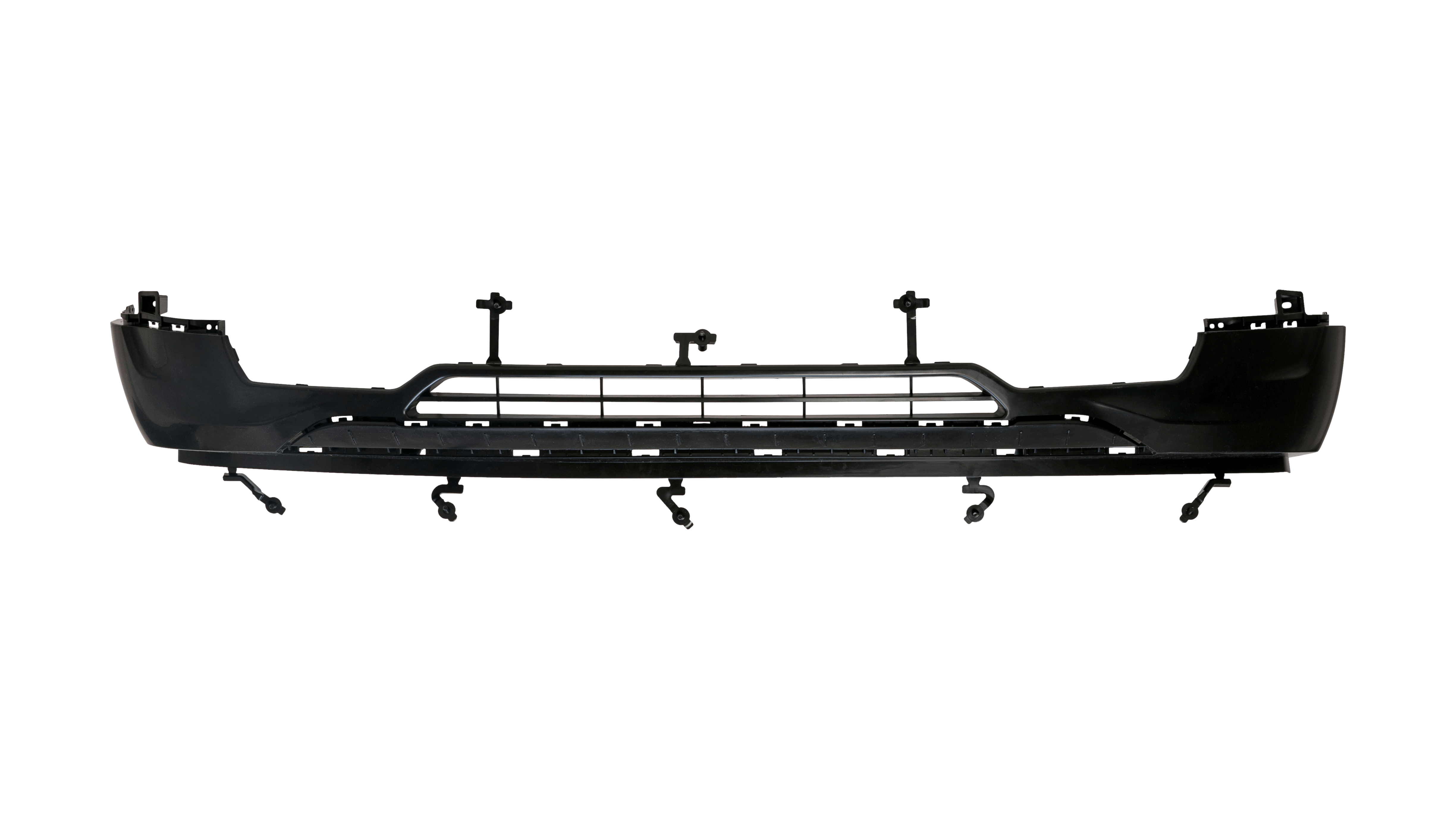

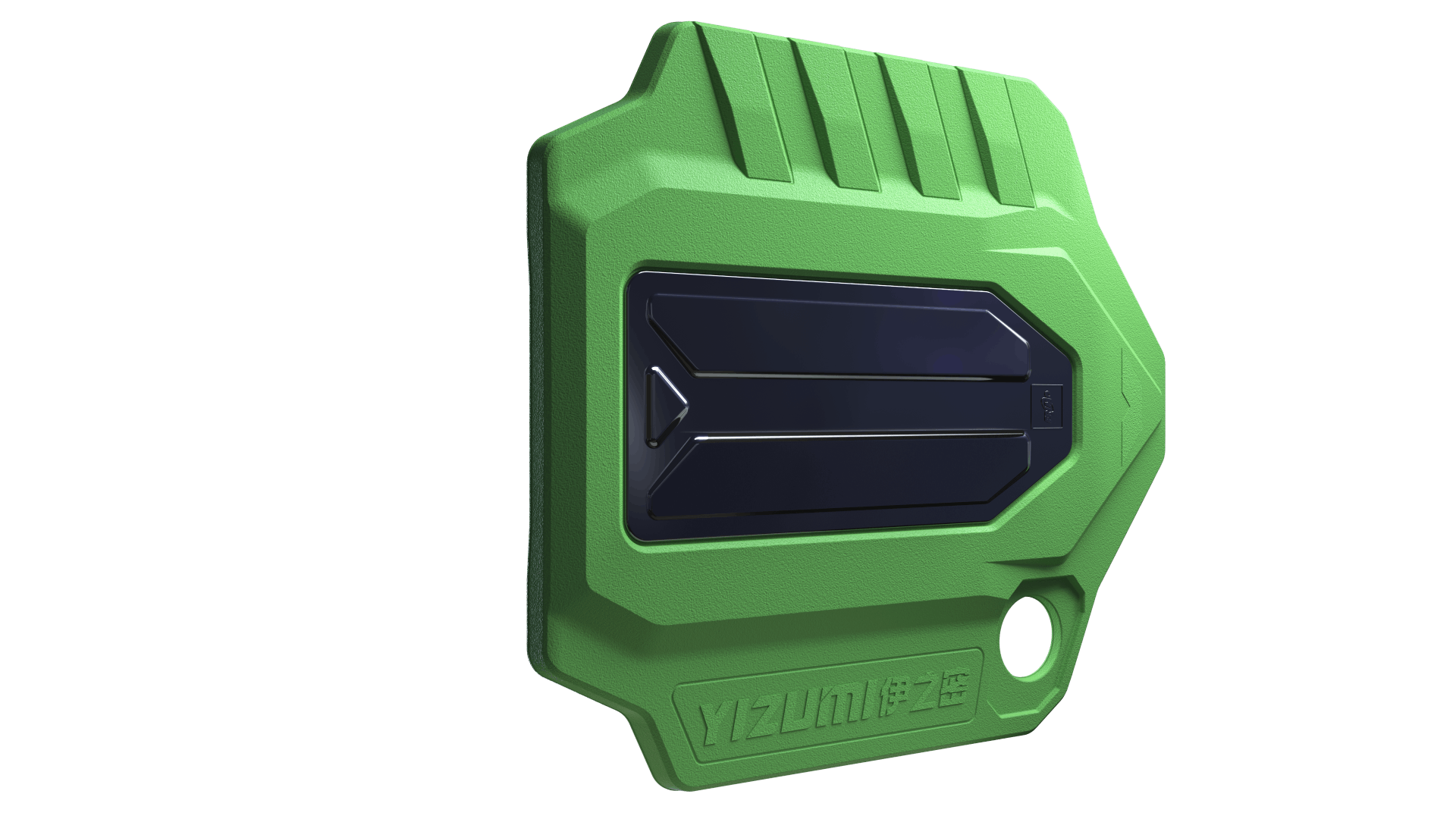

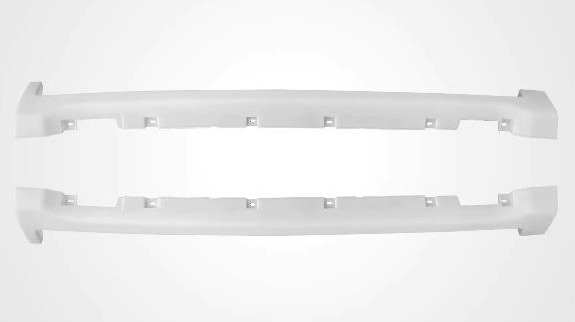

Exterior trim parts—High quality, high efficiency.

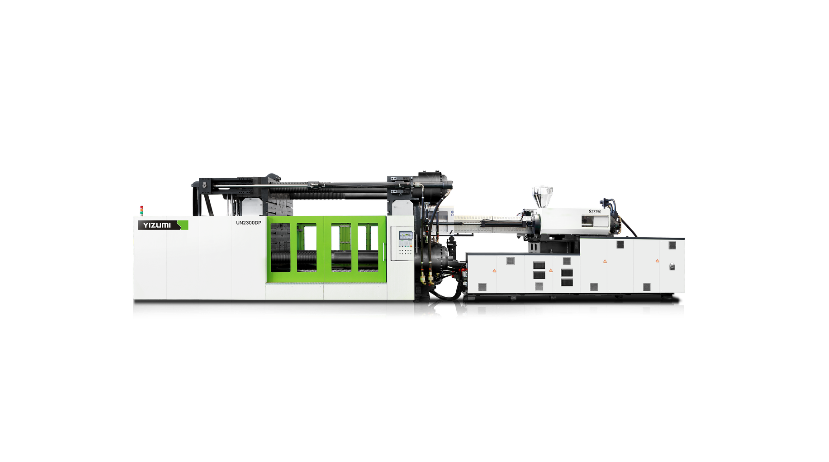

High safety secured by high quality: YIZUMI is well-acquainted with the production of high-quality modern interior trim parts and panels in the automobile Industry. We develop innovative solutions that are cost-effective, balanced in the purchase and use costs, and sustainable for our customers based on material properties and the advantages of different processes.

Application Highlights

Economic

Give full play to the advantages according to the advantages of materials and processes to achieve the goal of “using the right material in the right place.”

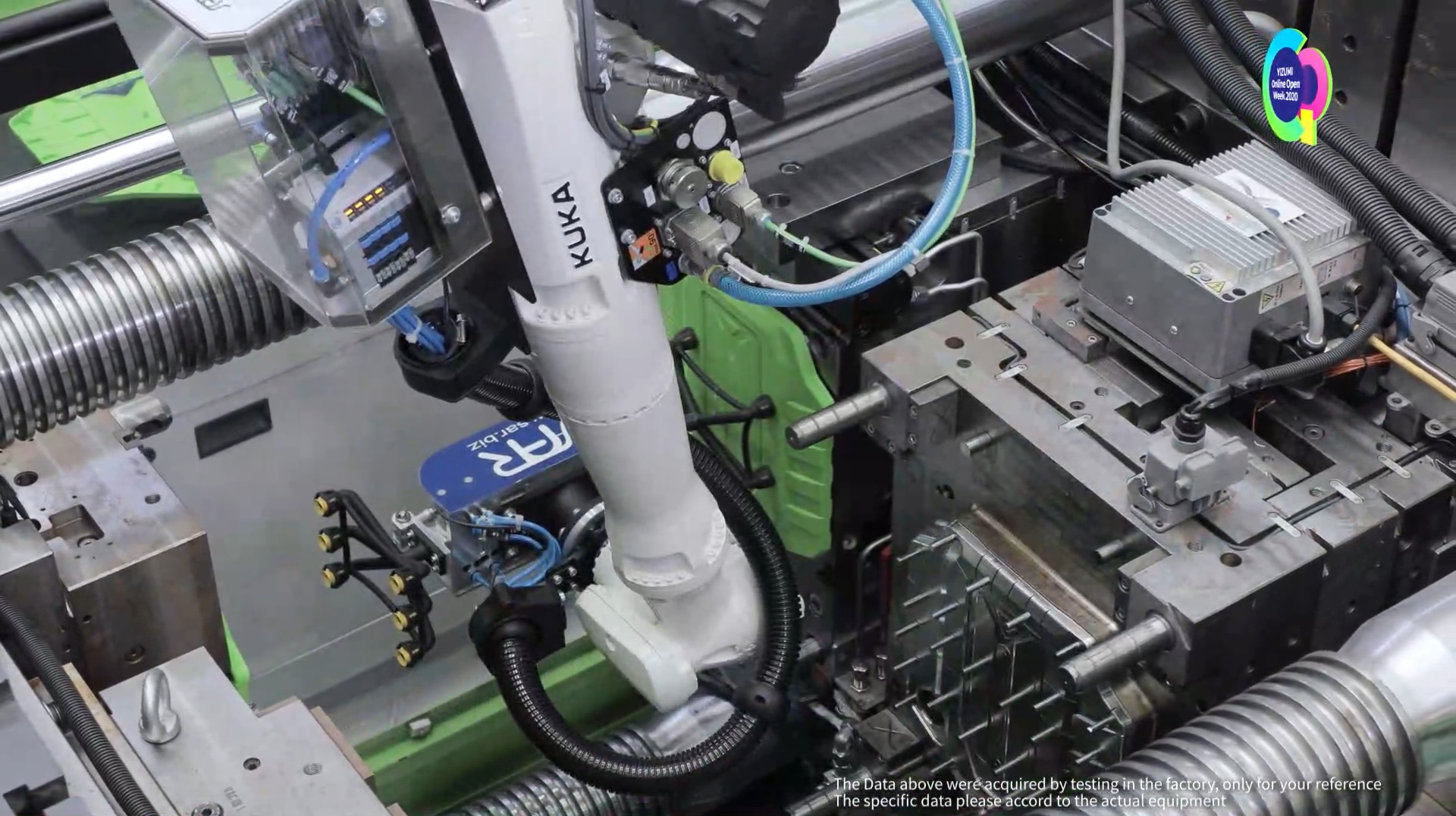

Efficient

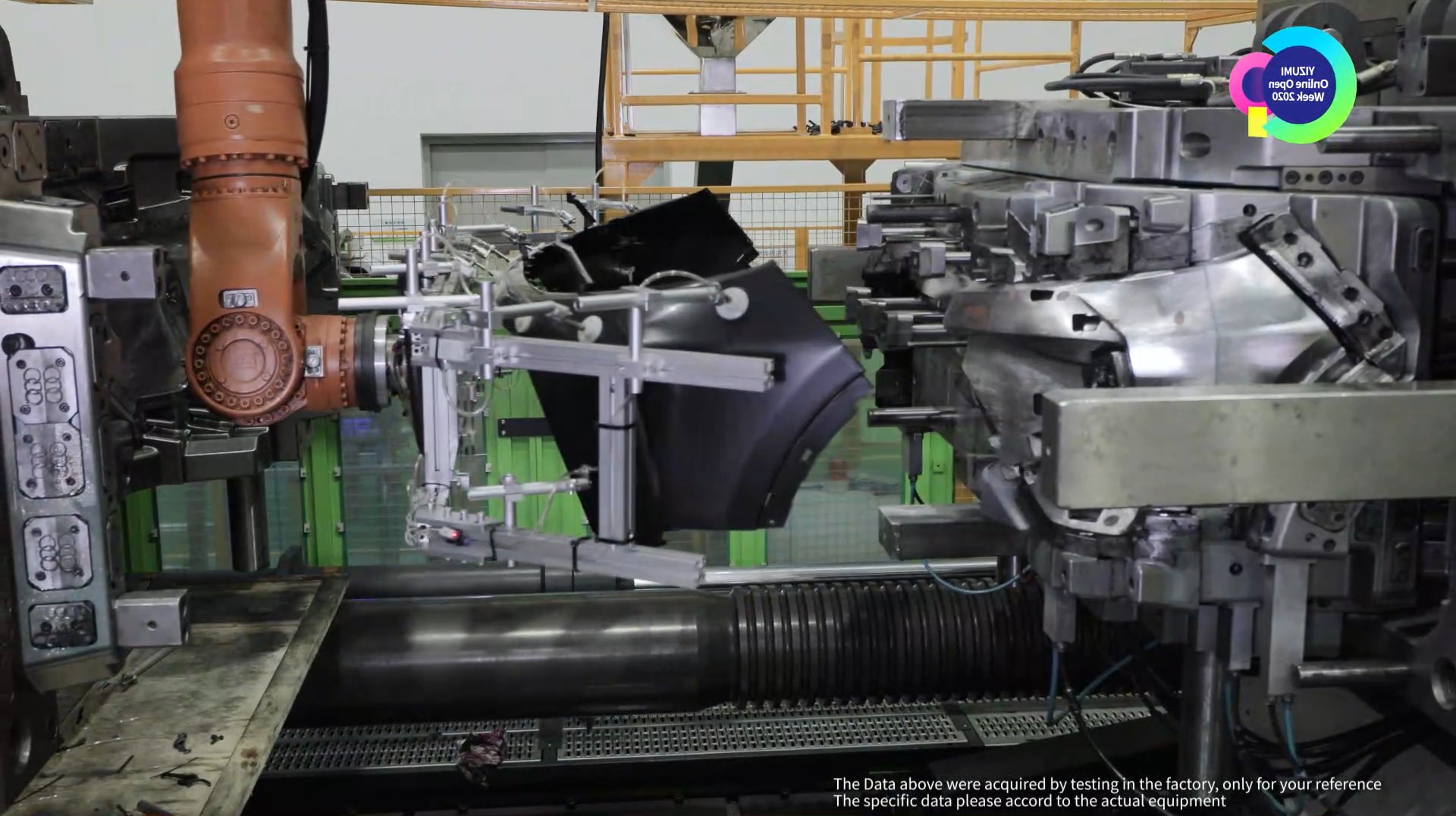

Provide overall solutions with a high automation level to realize automatic, unmanned, and information-based production.

Mature

Adopt standard modular design and proven personalization to meet different production needs.

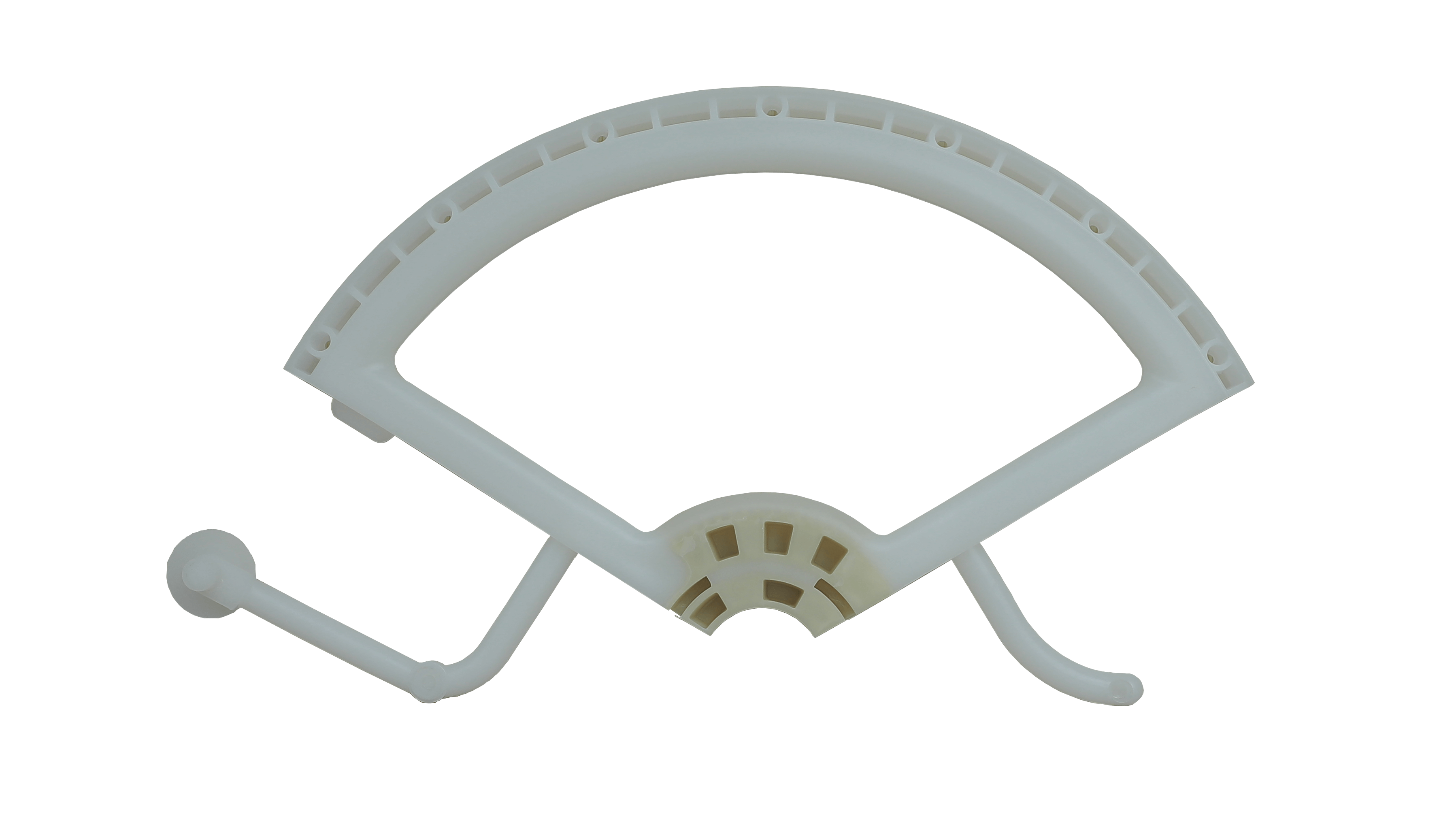

Exterior trim parts Application

Product Video

Relevant Recommendation

Relevant Products

Relevant Technologies

Service Process

01

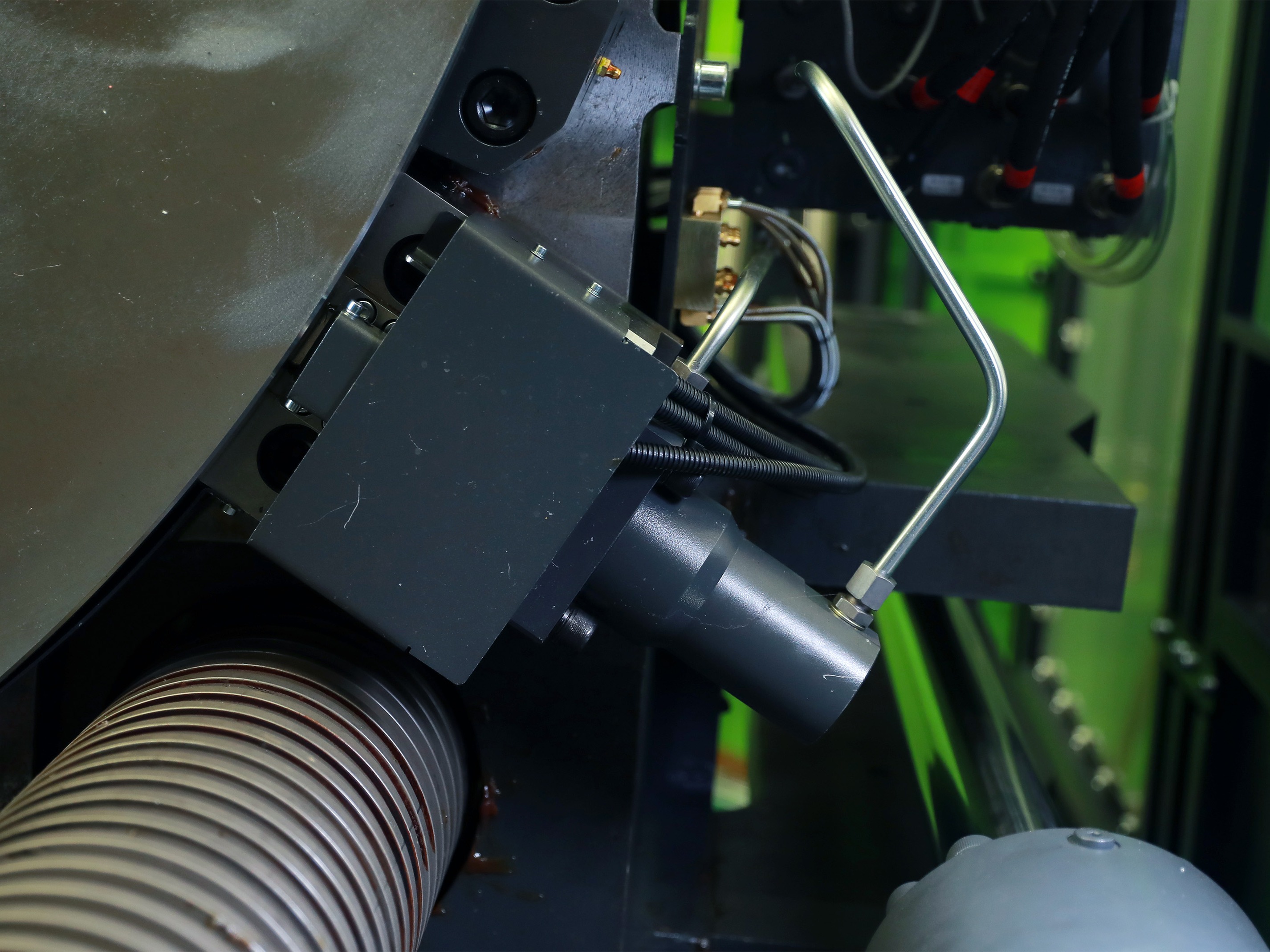

Process/Mold Analyse and Design

- Raw materials selection

- Product design

- Mold flow analysis

- Mold design suggestion

02

Equipment Selection Suggestions

- Product performance

- Product quality

- Ease of use

- Safety requirements

03

Whole Plant Planning Advice

- Planning of production line

- Arrangements for people, machines, and materials according to process flow

- Peripheral automation

- Smart connection

04

Delivery Solutions

- Professional installation and debugging

- On-site operation training

- Molding process training

05

After Sales Solutions

- YFO services

- Preventive maintenance

- Device upgrade

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.

Application Highlights

Product Video

Relevant Recommendation

Service Process

Contact Us

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.