Wide and clear sight

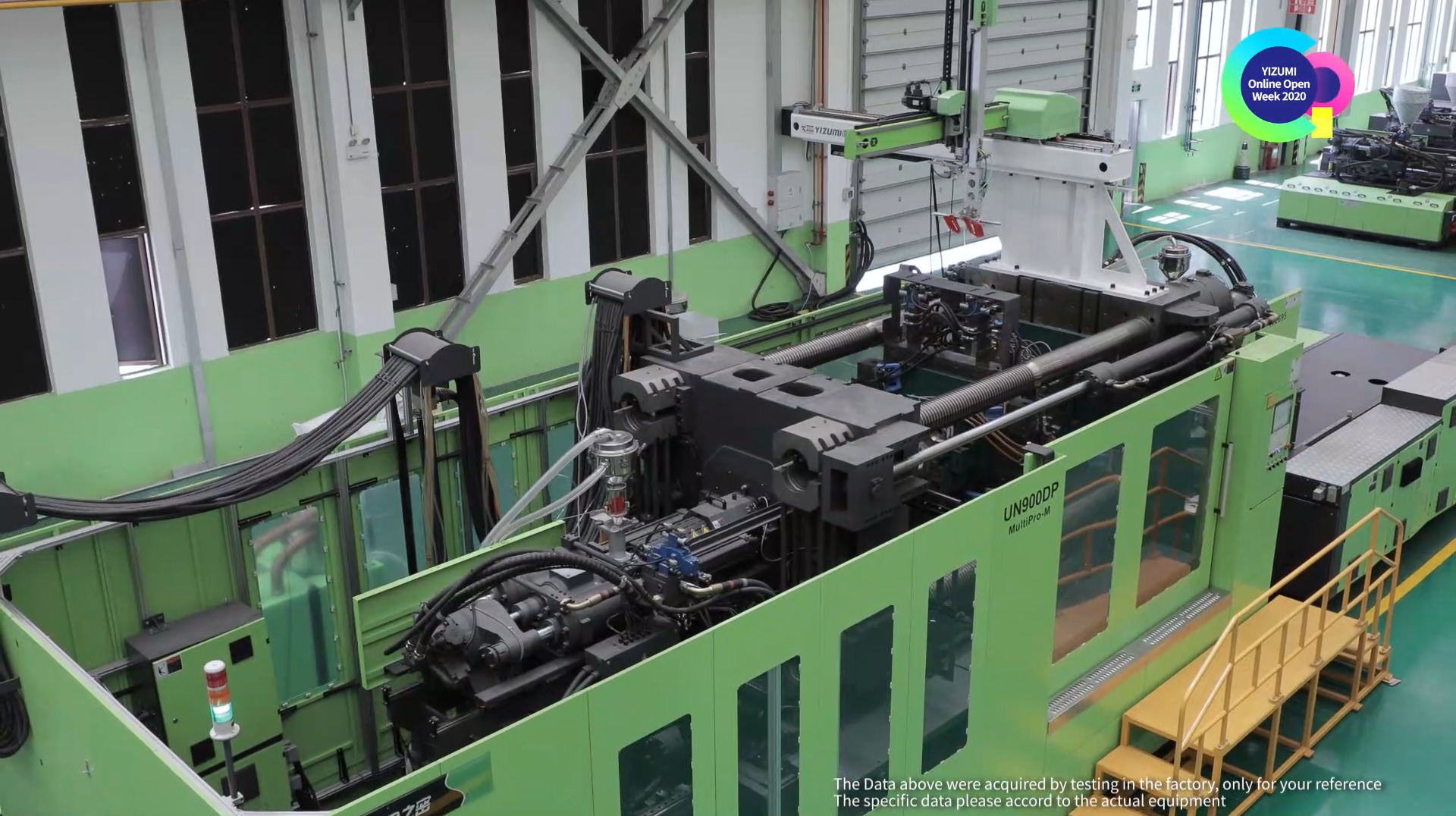

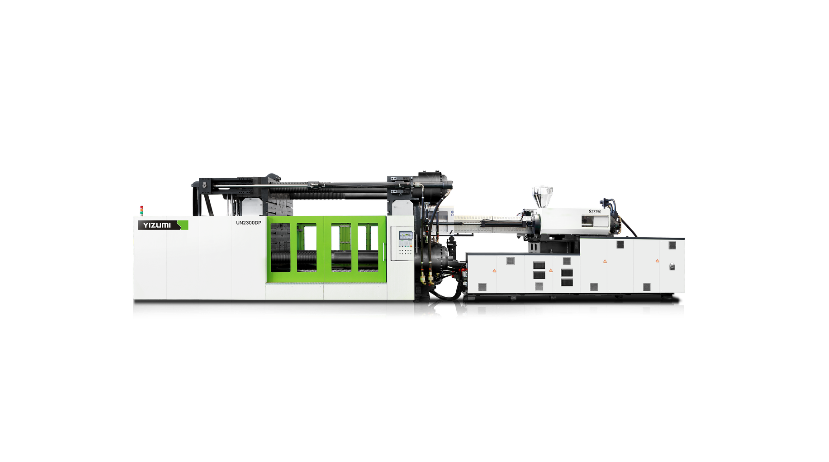

With injection molding solutions like single-color or multi-color, multi-material, multi-layer, and compression injection, Yizumi can achieve efficient and high-quality production of lighting parts.

Application Highlights

Customization

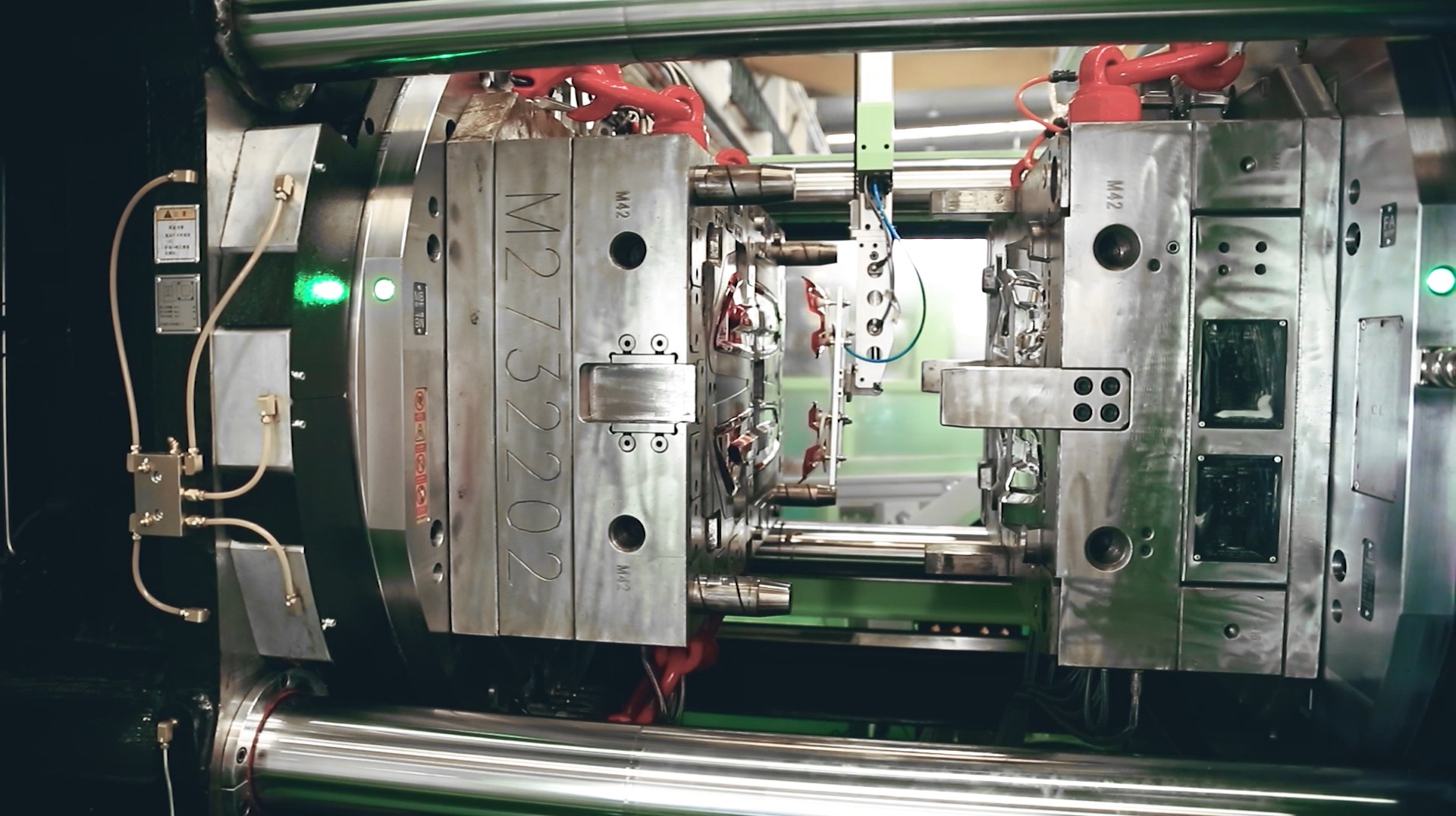

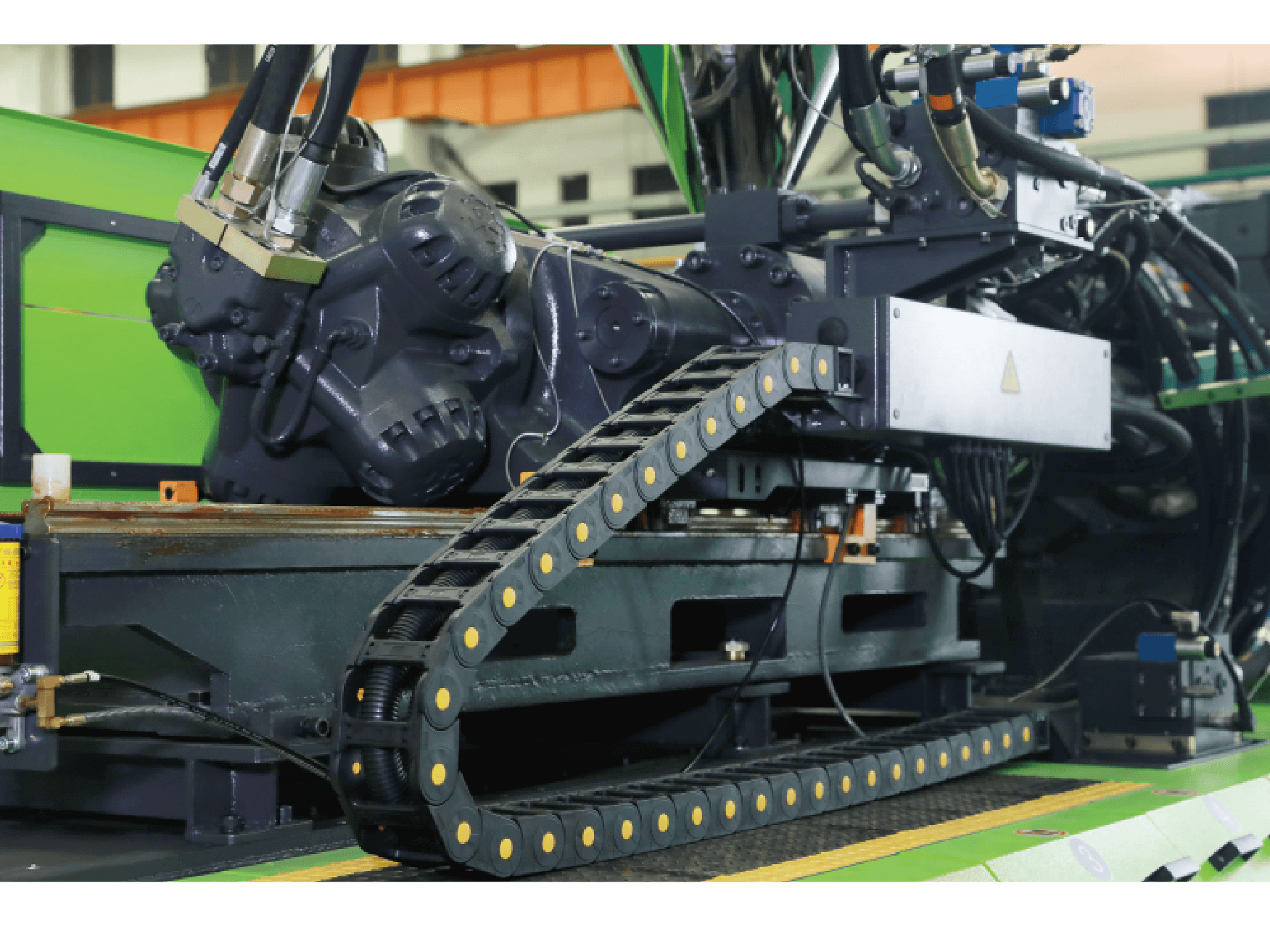

Customize multi-component injection molding machine to manufacture automotive lighting components.

High quality

Advanced technology and processes ensure high-quality products.

Automotive lighting Application

Product Video

Relevant Recommendation

Relevant Products

Relevant Technologies

Service Process

01

Process/Mold Analyse and Design

- Raw materials selection

- Product design

- Mold flow analysis

- Mold design suggestion

02

Equipment Selection Suggestions

- Product performance

- Product quality

- Ease of use

- Safety requirements

03

Whole Plant Planning Advice

- Planning of production line

- Arrangements for people, machines, and materials according to process flow

- Peripheral automation

- Smart connection

04

Delivery Solutions

- Professional installation and debugging

- On-site operation training

- Molding process training

05

After Sales Solutions

- YFO services

- Preventive maintenance

- Device upgrade

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.

Application Highlights

Product Video

Relevant Recommendation

Service Process

Contact Us

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.