Application Highlights

Heavy-duty Die Casting Machines

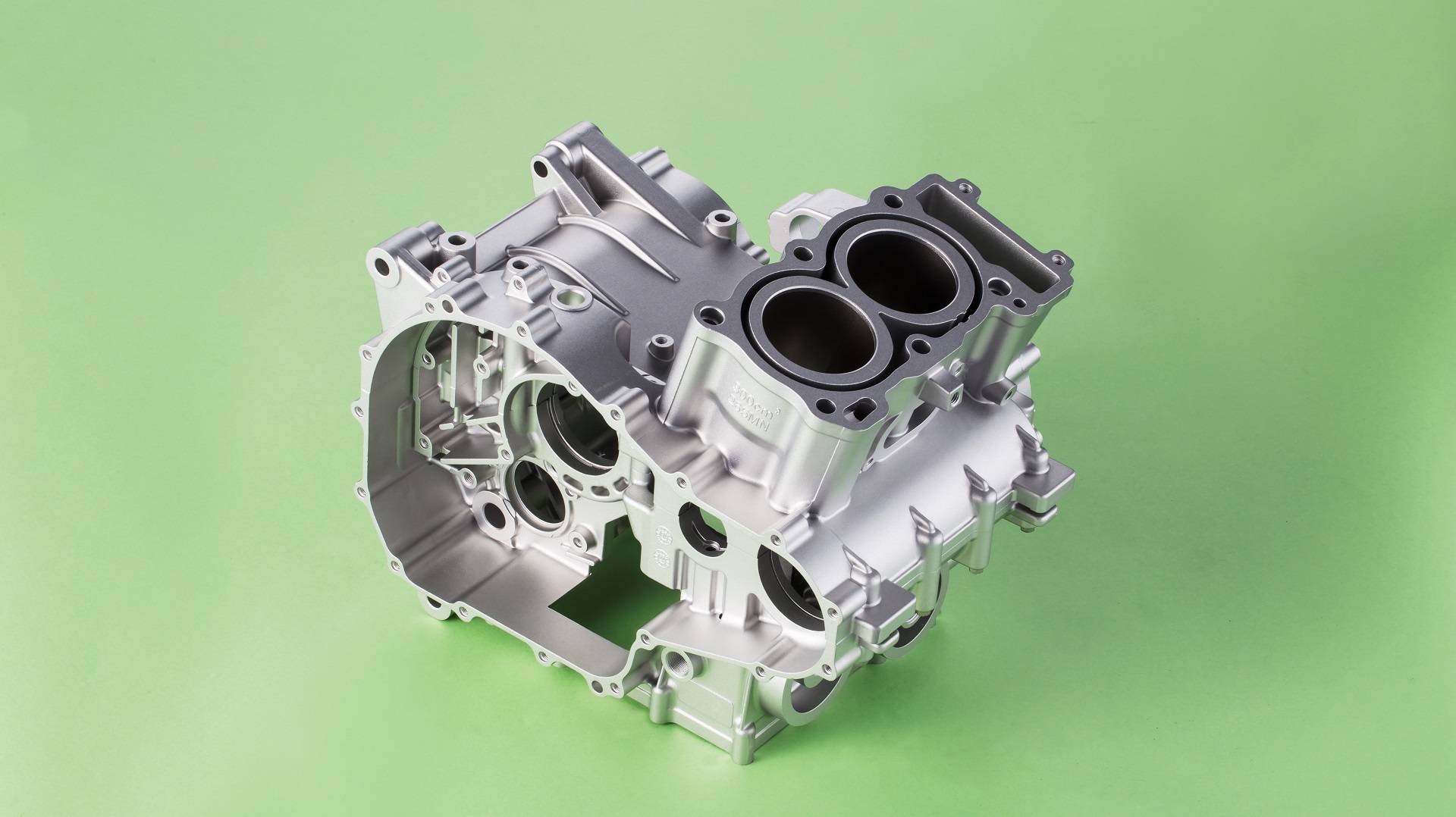

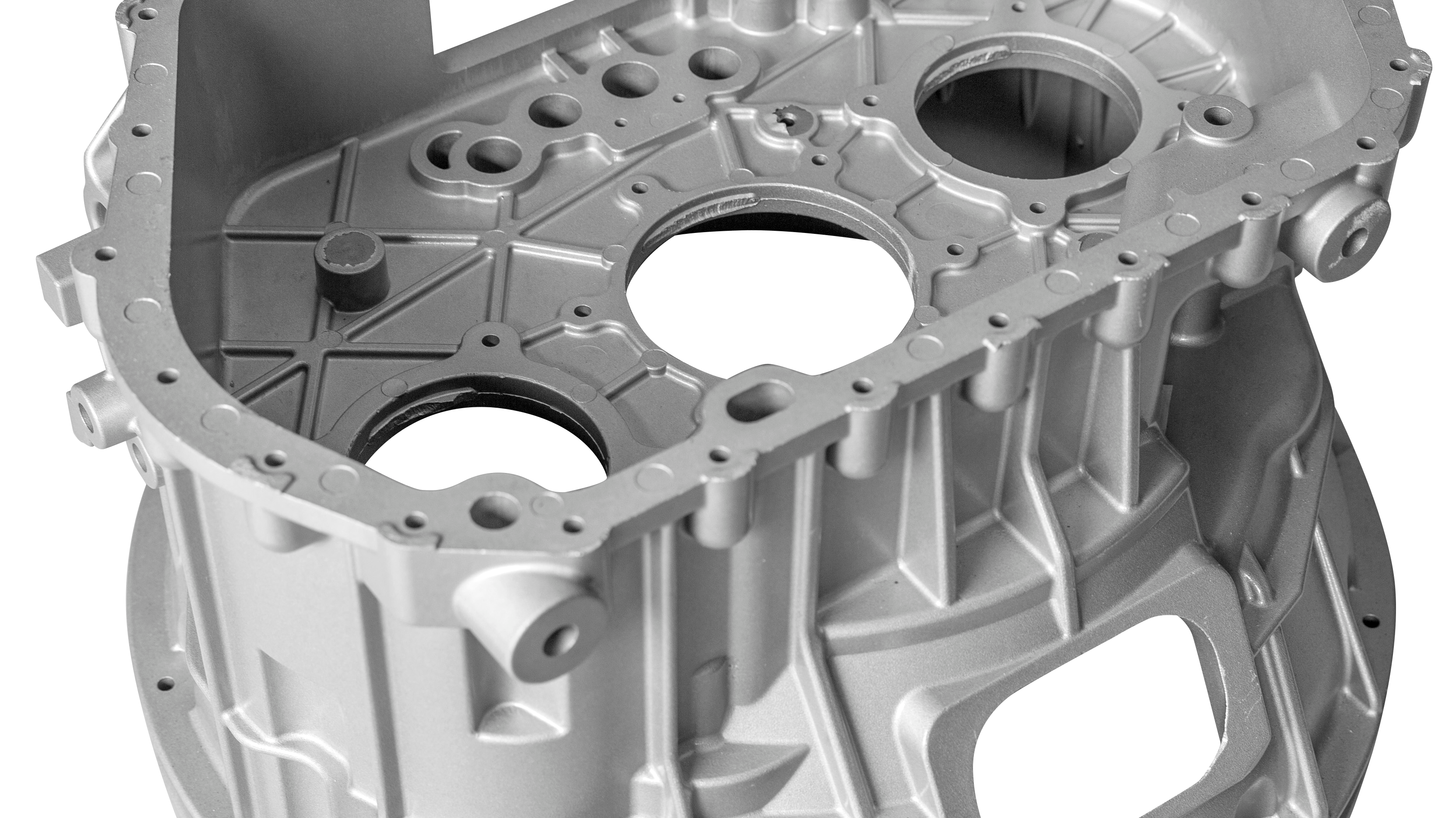

Automobile engine blocks and transmission housings of heavy-duty trucks are large in volume and weight, requiring the use of 2500-5000 tonnage heavy-duty die-casting machines.

Innovation Advantages

Changing from gravity casting iron parts to aluminum alloy die castings with thinner average wall thickness reduces the weight of parts by more than 70%.

Core Technology

To fulfill the requirements of automotive parts for high-quality and traceability, the system is equipped with a high performance injection unit to provide strong filling capability and short pressure build-up time. The real-time control technology is used to ensure the stability of processes.

Process Technology

Combined with automatic insertion technology, it can achieve fully automatic die-casting production. The annual output of a single production line can exceed 100,000 units. We also provide one-stop solutions for customers.

Powertrain Parts Application

Service Process

- Raw materials selection

- Product design

- Mold flow analysis

- Mold design suggestion

- Product performance

- Product quality

- Ease of use

- Safety requirements

- Planning of production line

- Arrangements for people, machines, and materials according to process flow

- Peripheral automation

- Smart connection

- Professional installation and debugging

- On-site operation training

- Molding process training

- YFO services

- Preventive maintenance

- Device upgrade

![[old]LEAP Series Die Casting Machine](/uploads/2022-12-14/71015ea3-f53f-43c6-9176-88fc631e01a11670947886135.png)

![[old] HII-S Series High-end Cold Chamber Die Casting Machine(1000-5000T)](/uploads/2023-06-05/d58e81d3-4969-46b7-801e-b4f2736113071685956662265.png)

![[old] HII-S Series High-end Cold Chamber Die Casting Machine(180-900T)](/uploads/2023-01-05/b67dc467-19d1-4dec-9030-6d6e2faf71d71672908700118.png)