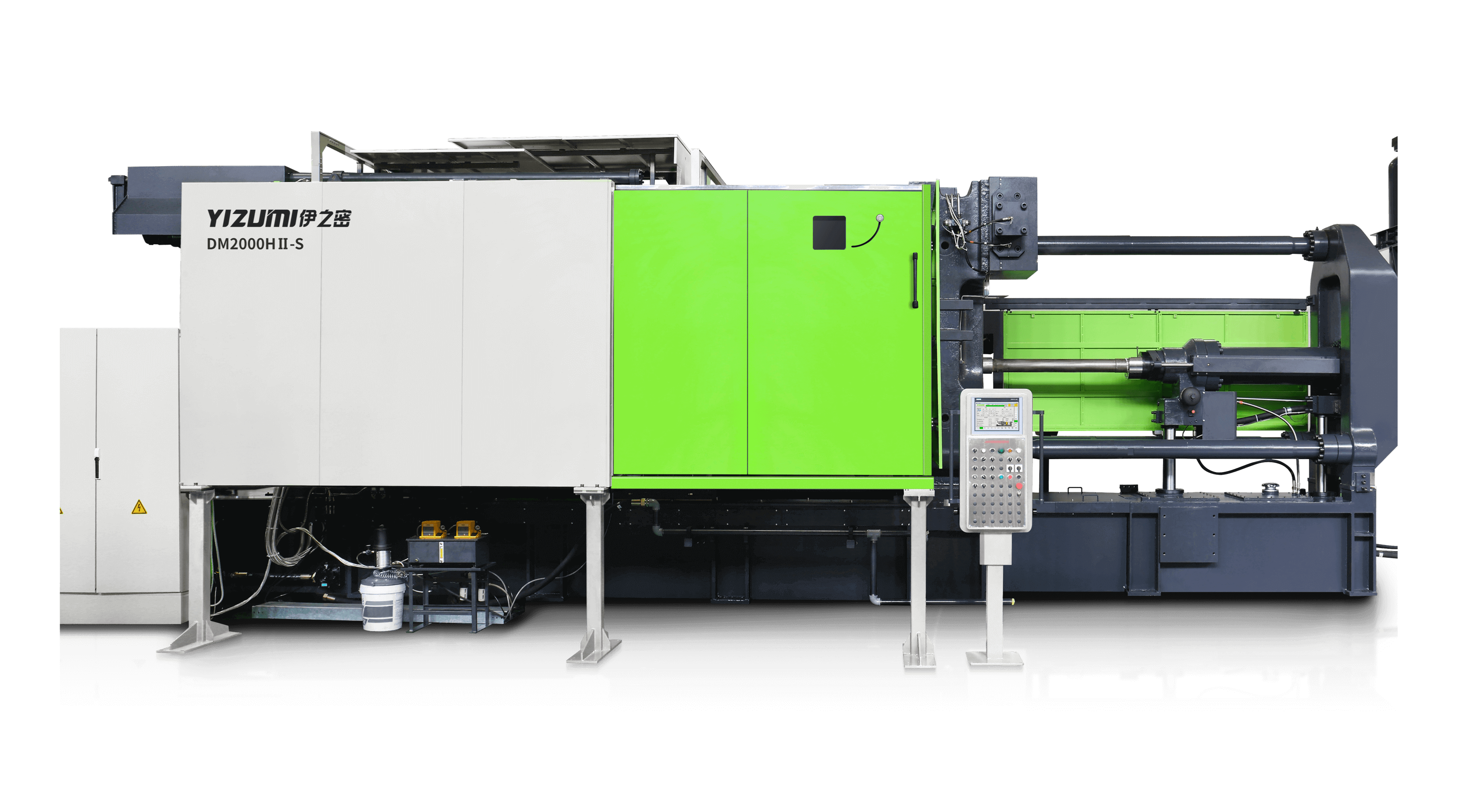

Yi-Cast Injection System

Complete closed-loop real-time control of slow speed, fast speed, and intensification pressure. No need for too much user adjustment. Just set the required values directly.

Yi-drive Pump Unit

The pump station adopts servo + Feed technology with a high energy efficiency that saves more electricity for customers.

ORCA Control System

The control system employs an IPC industrial computer equipped with a 24 inch touch panel to meet the needs for precise control of the injection machine.

Intelligent Die Opening / Closing System

Accurate control of any die opening position. The repeatability accuracy of the die opening position is up to ±1mm. It also offers automatic clamping force detection and die height adjustment features.

Product Video

Industry Application

Relevant Recommendation

Relevant Products

Relevant Technologies

Service Process

01

Process/Mold Analyse and Design

- Raw materials selection

- Product design

- Mold flow analysis

- Mold design suggestion

02

Equipment Selection Suggestions

- Product performance

- Product quality

- Ease of use

- Safety requirements

03

Whole Plant Planning Advice

- Planning of production line

- Arrangements for people, machines, and materials according to process flow

- Peripheral automation

- Smart connection

04

Delivery Solutions

- Professional installation and debugging

- On-site operation training

- Molding process training

05

After Sales Solutions

- YFO services

- Preventive maintenance

- Device upgrade

Download

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.