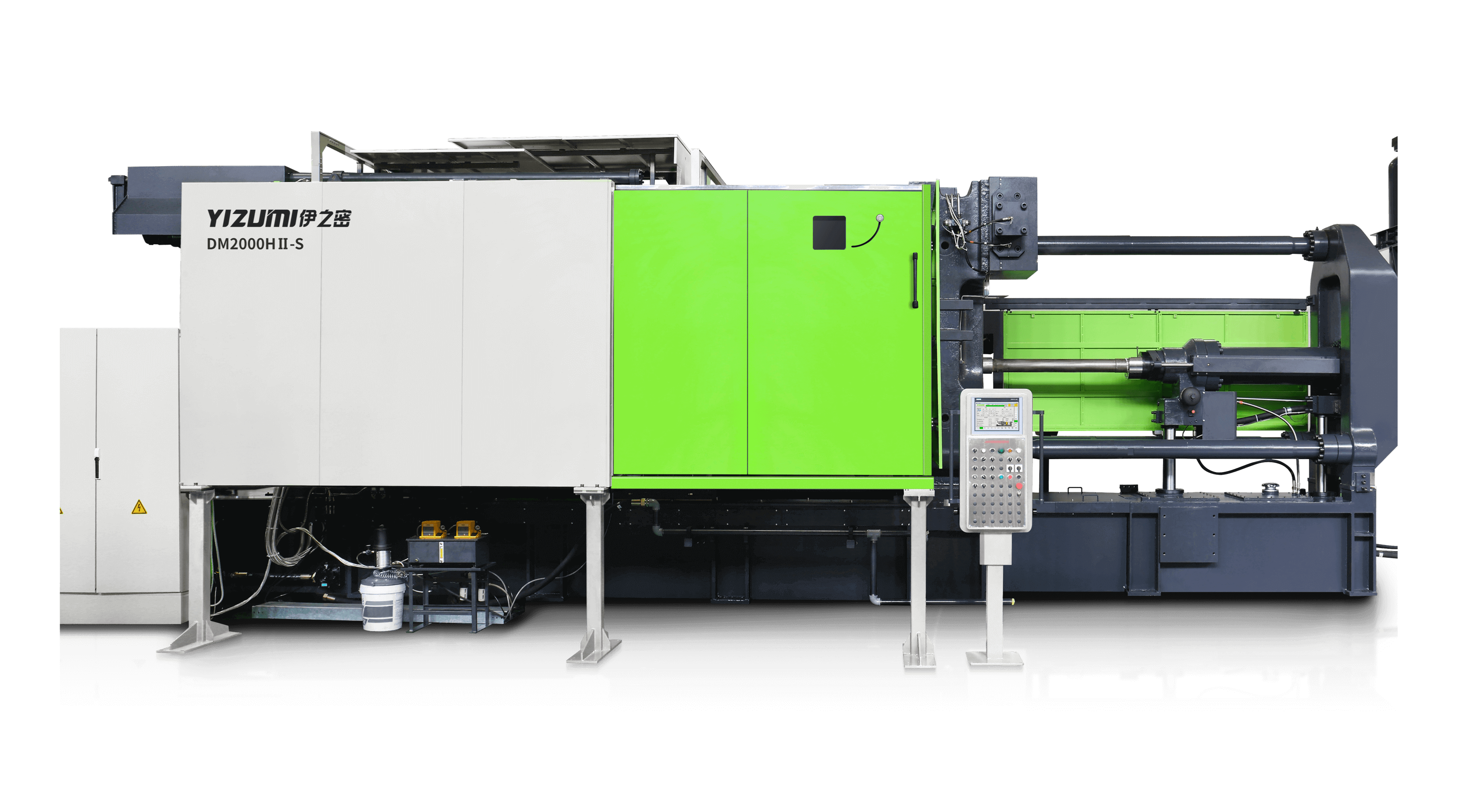

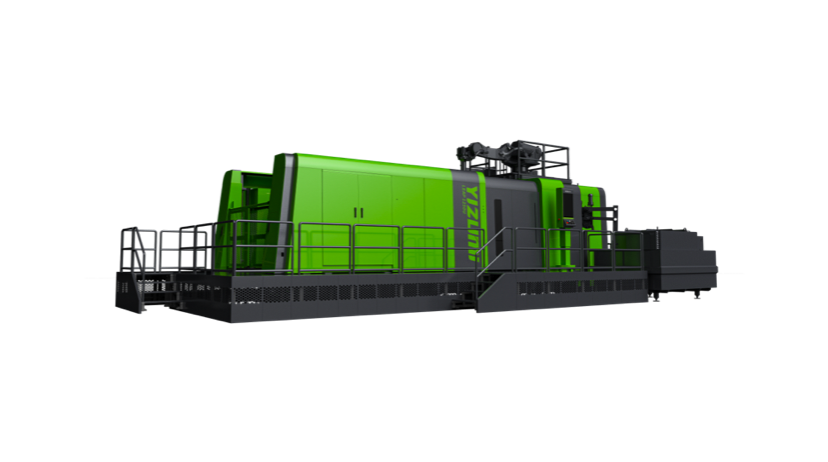

Machine Introduction

Machine Introduction

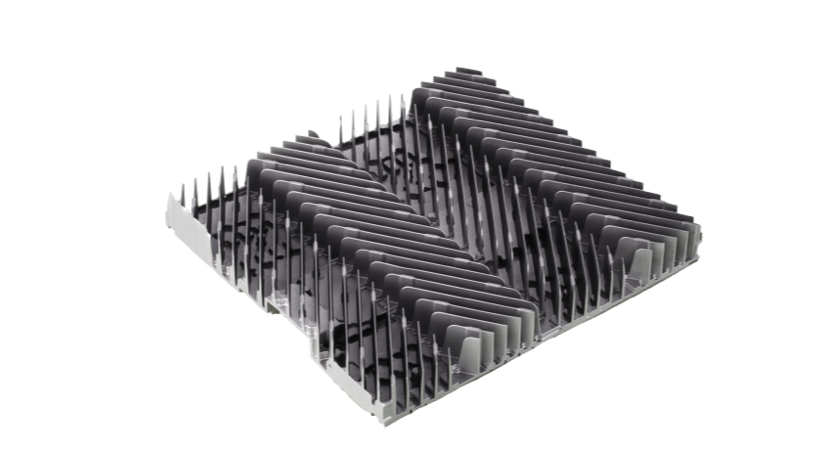

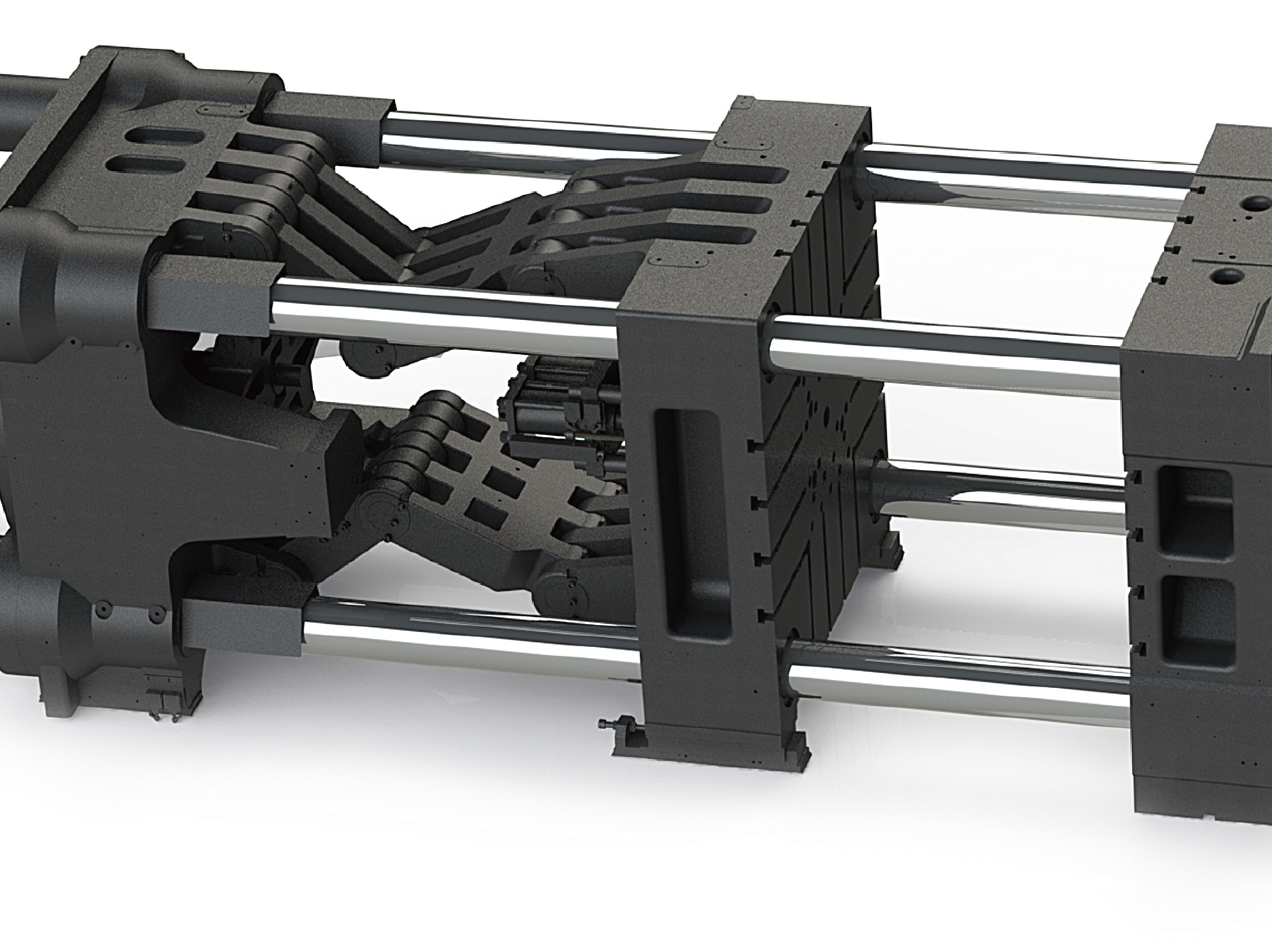

Clamping Unit

Re-Designed high rigidity platen

- Further increased platen rigidity protects the die casting tools during operation;

- A new design based on FEM analysis offers an even distribution of force by minimized platen bending.-

- A new design based on FEM analysis offers an even distribution of force by minimized platen bending.-

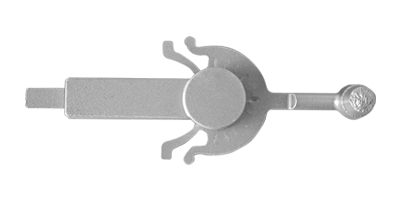

Designed for extended service life

- Re-designed toggle geometry based on detailed movement simulations provides improved platen movement characteristics;

- which extends the toggle service life and further decreases the closing and opening time.

- which extends the toggle service life and further decreases the closing and opening time.

Optimized Toggle Lubrication Design

Improved and centrally located toggle system lubrication and grease system ease the operation of the machine so that an extended machine service life is ensured.

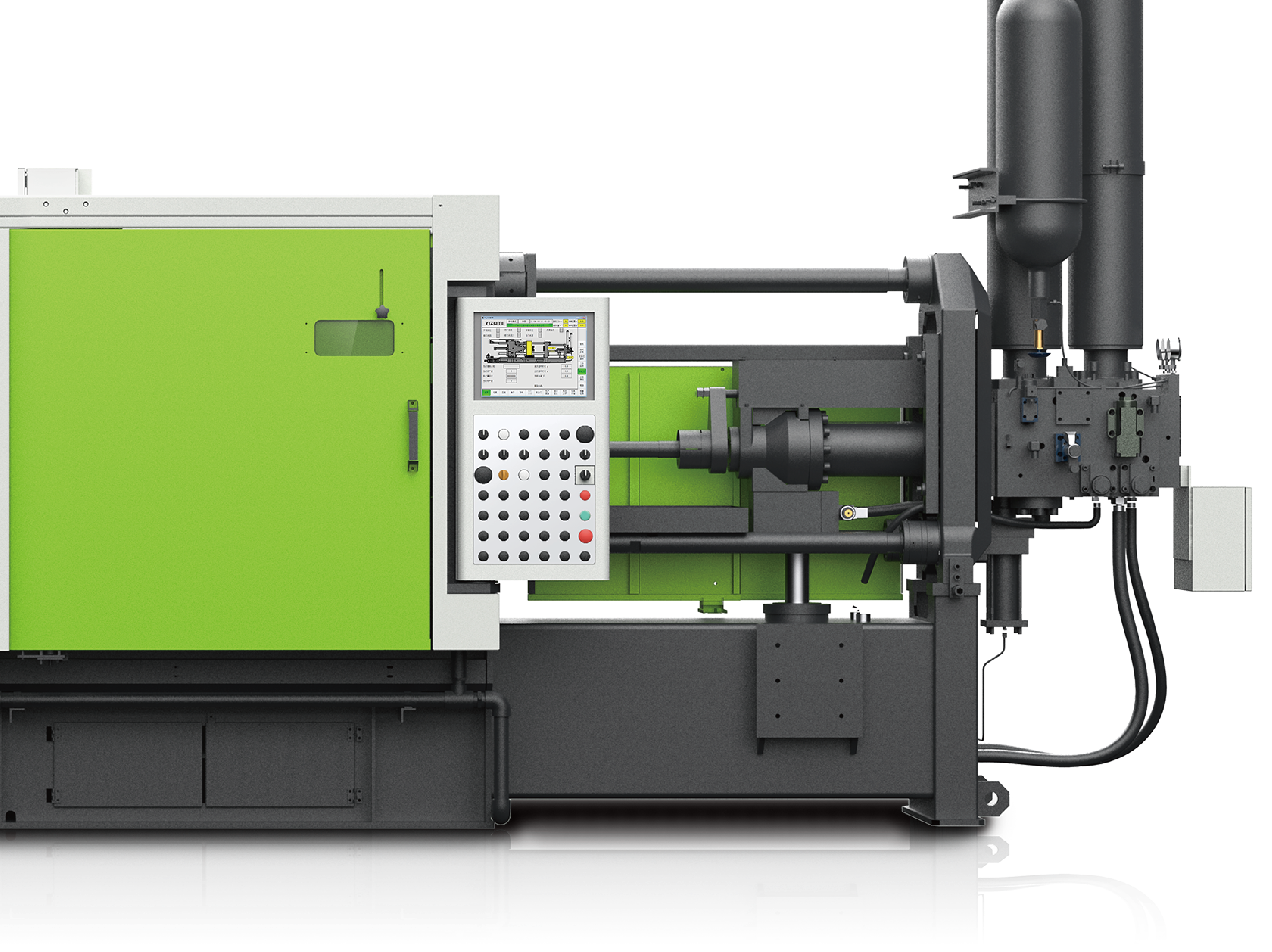

Injection Unit

Pressure build-up time shortened by 30%

Further improved pressure build-up time by over 30%. The HII-S pressure build-up time offers great performance to any casting process.

Precision improved by 20%

The HII-S provides a high standard of precision to switch over to the cavity filling phase. A repeatability of max +/-2mm satisfies the highest requirements.

Fast and Precise Hydraulic Drive System

- The third generation servo drive offers even Less noise emissions if compared to the previous design. System noise reduction of about 20%;

- Stabilizing power surges automatically for up to 5 minutes, this system offers great operational stability even with fluctuating main power;

- This efficient servo pump system ensures the lowest possible oil temperatures, further enhancing operational efficiency;

- Reduced system response time improves reaction time and the highest operational performance.

- Stabilizing power surges automatically for up to 5 minutes, this system offers great operational stability even with fluctuating main power;

- This efficient servo pump system ensures the lowest possible oil temperatures, further enhancing operational efficiency;

- Reduced system response time improves reaction time and the highest operational performance.

International Standard Electrical Control System

- The integrated operating panel is easy to use and saves time for the operator as well as the casting process engineers;

- Further optimized layout and structure of our HMI increases flexibility in managing machine functions via a large touchscreen;

- Intuitive and easy-to-understand maintenance functions, such as maintenance tips, comprehensive alarm messages as well as operation guidance, increase operational efficiency.

- Further optimized layout and structure of our HMI increases flexibility in managing machine functions via a large touchscreen;

- Intuitive and easy-to-understand maintenance functions, such as maintenance tips, comprehensive alarm messages as well as operation guidance, increase operational efficiency.

Industry Application

Relevant Recommendation

Relevant Products

Relevant Technologies

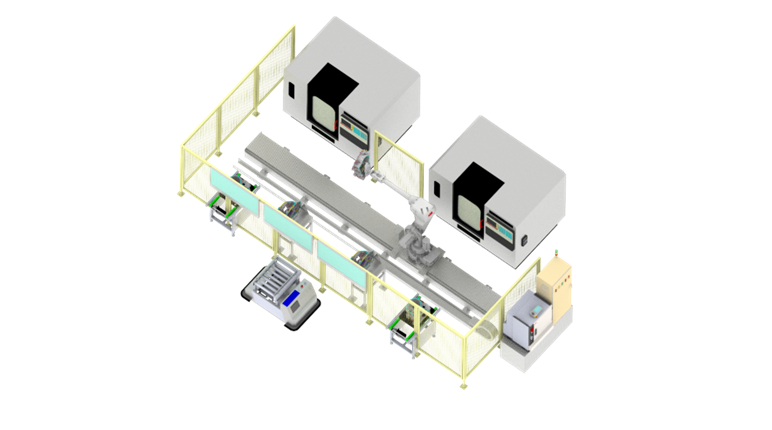

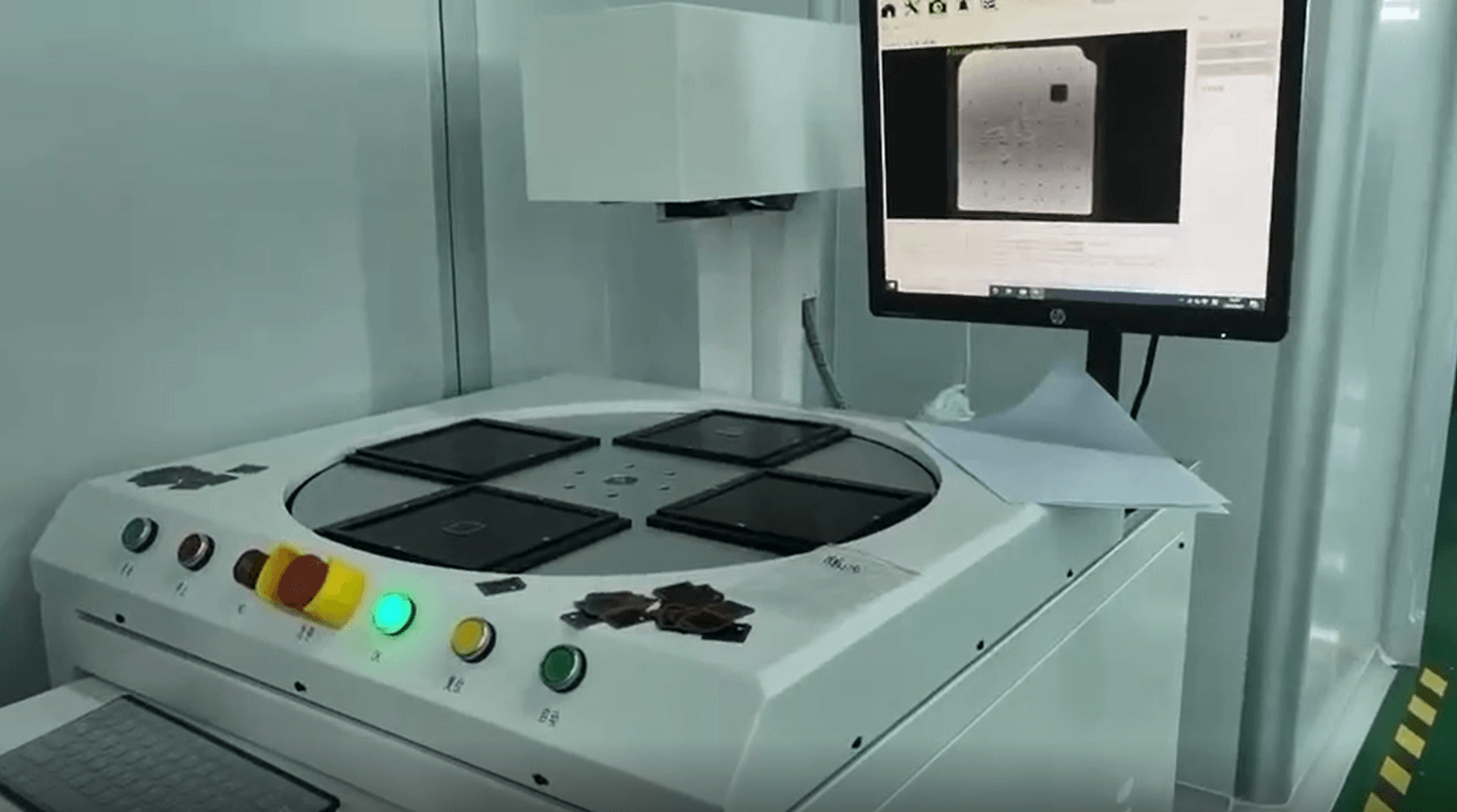

Relevant Automation

Service Process

01

Process/Mold Analyse and Design

- Raw materials selection

- Product design

- Mold flow analysis

- Mold design suggestion

02

Equipment Selection Suggestions

- Product performance

- Product quality

- Ease of use

- Safety requirements

03

Whole Plant Planning Advice

- Planning of production line

- Arrangements for people, machines, and materials according to process flow

- Peripheral automation

- Smart connection

04

Delivery Solutions

- Professional installation and debugging

- On-site operation training

- Molding process training

05

After Sales Solutions

- YFO services

- Preventive maintenance

- Device upgrade

Download

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.