Application Highlights

Innovative Product Design

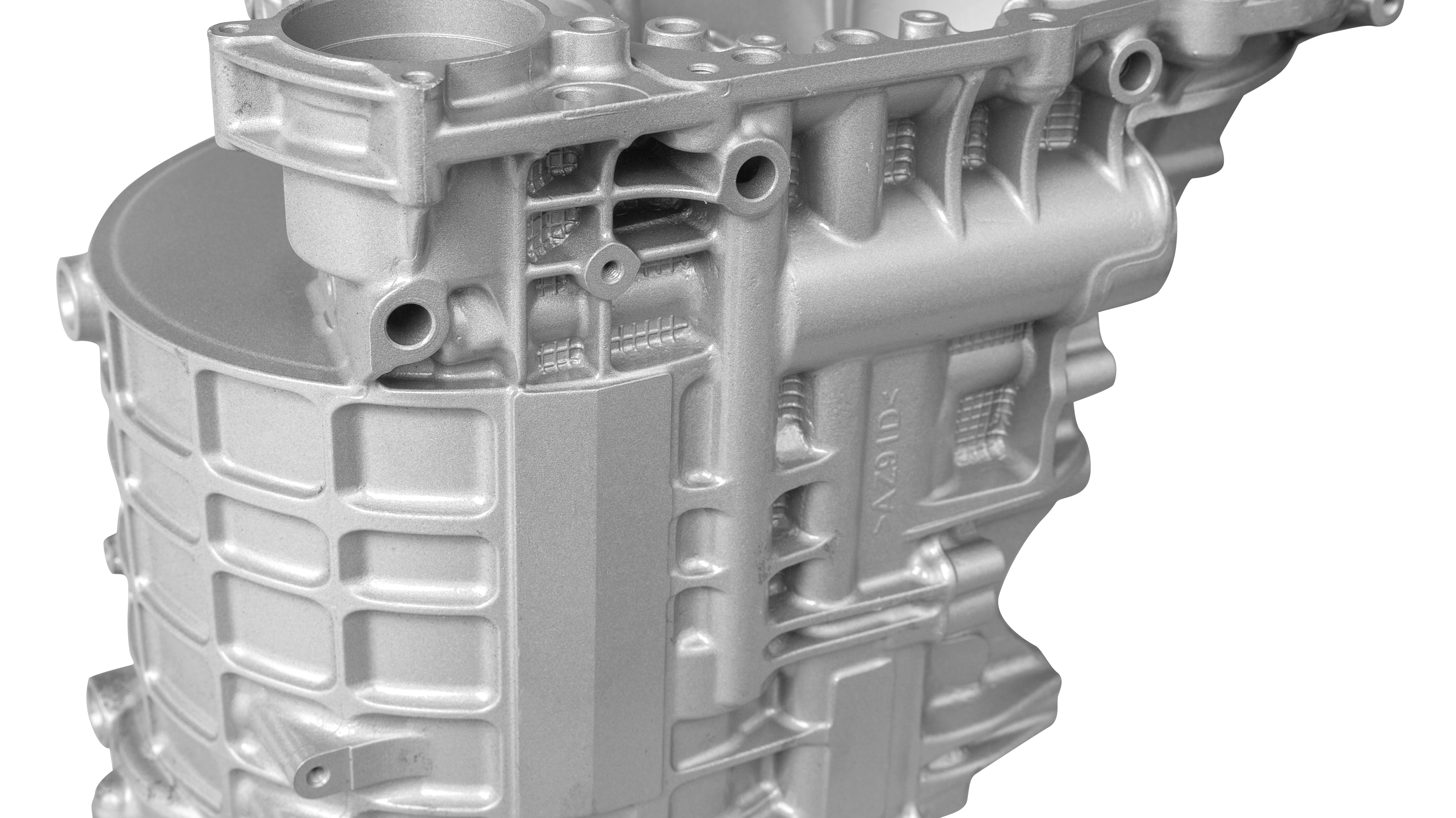

Electric drives, motors, and electric control systems for the new energy vehicles are increasingly integrated, changing from single-function parts to integrated multi-functional components. The tonnage of the required die-casting machine is also gradually rising to 1250-3500 tons.

Innovation Advantages

Die castings with uneven wall thickness have very high-quality requirements. Sections that need local cooling channels or have thick and large threaded holes have special requirements for strength or leakproof. Some products come with inserts.

Core Technology

The LEAP series die-casting machine equipped with the self-developed Yi-cast real-time controlled injection system offers ultra-high dynamic injection force to ensure sufficient filling capacity for thin-walled products. Extremely fast pressure build-up ensures the ability to compensate shrinkage in the thick and large sections.

Process Technology

YIZUMI's highly flexible production cell allows for quick changeover between different products of the same grade and the monitoring of speed and extrusion stroke ensures high-quality control and traceability of various products.

New Energy Auto Parts Application

Service Process

- Raw materials selection

- Product design

- Mold flow analysis

- Mold design suggestion

- Product performance

- Product quality

- Ease of use

- Safety requirements

- Planning of production line

- Arrangements for people, machines, and materials according to process flow

- Peripheral automation

- Smart connection

- Professional installation and debugging

- On-site operation training

- Molding process training

- YFO services

- Preventive maintenance

- Device upgrade

![[old]LEAP Series Die Casting Machine](/uploads/2022-12-14/71015ea3-f53f-43c6-9176-88fc631e01a11670947886135.png)