Application Highlights

Innovative Product Design

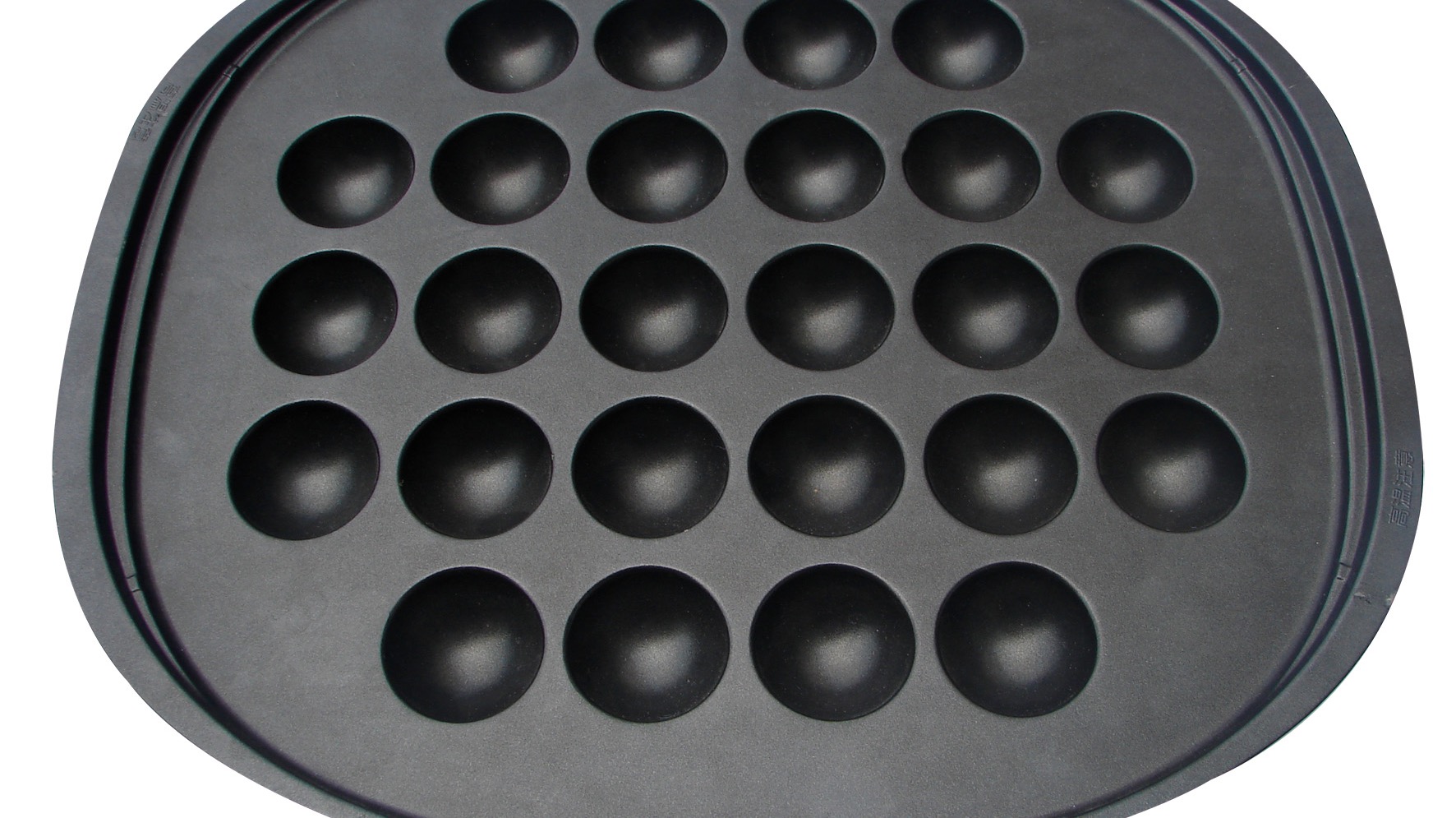

This kind of product has a requirement of a non-stick pan, and the working surface of the product should be treated with Teflon, due to the need to cycle heat in the working process, to prevent foaming, this kind of die casting products have strict gas content requirements.

Innovation Advantages

Whether using magnesium or aluminum alloy, our experience with nearly 500 mobile phone medium plate machines worldwide proves that our high-speed small die casting machine solution is the best choice for your precision structural parts.

Key Technology

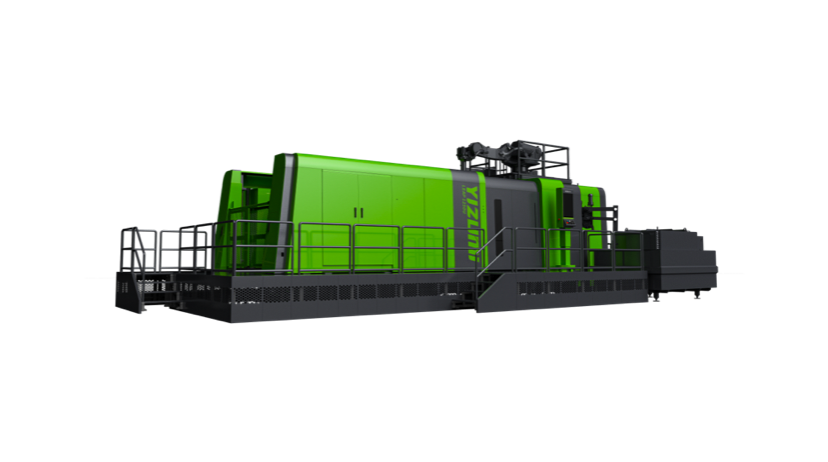

A mature and stable H2 series high-performance small and medium die casting machine, equipped with fully integrated soup feeding, spray and parts taking equipment, makes the operation of the whole die casting unit into an integrated machine.

Technology

The stable ultra-low speed performance of the Imi die casting machine is combined with optimized high speed starting points. , ensures that there is no enrolling air in the filling process of the die casting, and minimizes the gas content of the die casting. It provides a sufficient guarantee for the quality of small household appliances under heat.

Baking Pan Parts Application

Service Process

- Raw materials selection

- Product design

- Mold flow analysis

- Mold design suggestion

- Product performance

- Product quality

- Ease of use

- Safety requirements

- Planning of production line

- Arrangements for people, machines, and materials according to process flow

- Peripheral automation

- Smart connection

- Professional installation and debugging

- On-site operation training

- Molding process training

- YFO services

- Preventive maintenance

- Device upgrade