Who needs a small injection molding machine?

Abstract:

Who needs a small injection molding machine and explore how YIZUMI's C-frame series meets the demands of low volume manufacturing, engineering prototypes, small businesses, hobbyists, and educational institutions.

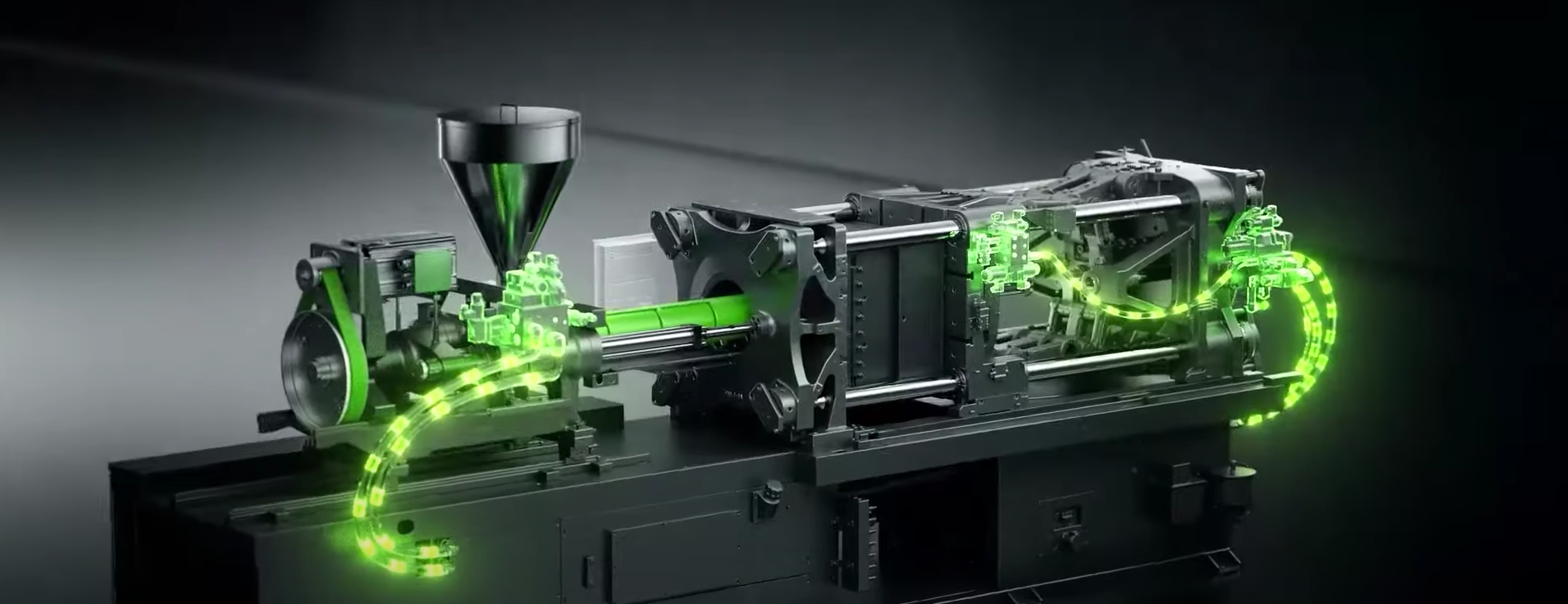

In the world of manufacturing, the right equipment can make all the difference. When it comes to producing small, precise parts, a small injection molding machine like YIZUMI's C-frame series can be a game changer. But who exactly needs this type of machinery? In this article, we will explore various scenarios where small injection machines excel, including low-volume manufacturing, engineering prototypes, small businesses, hobbyists, and educational institutions.

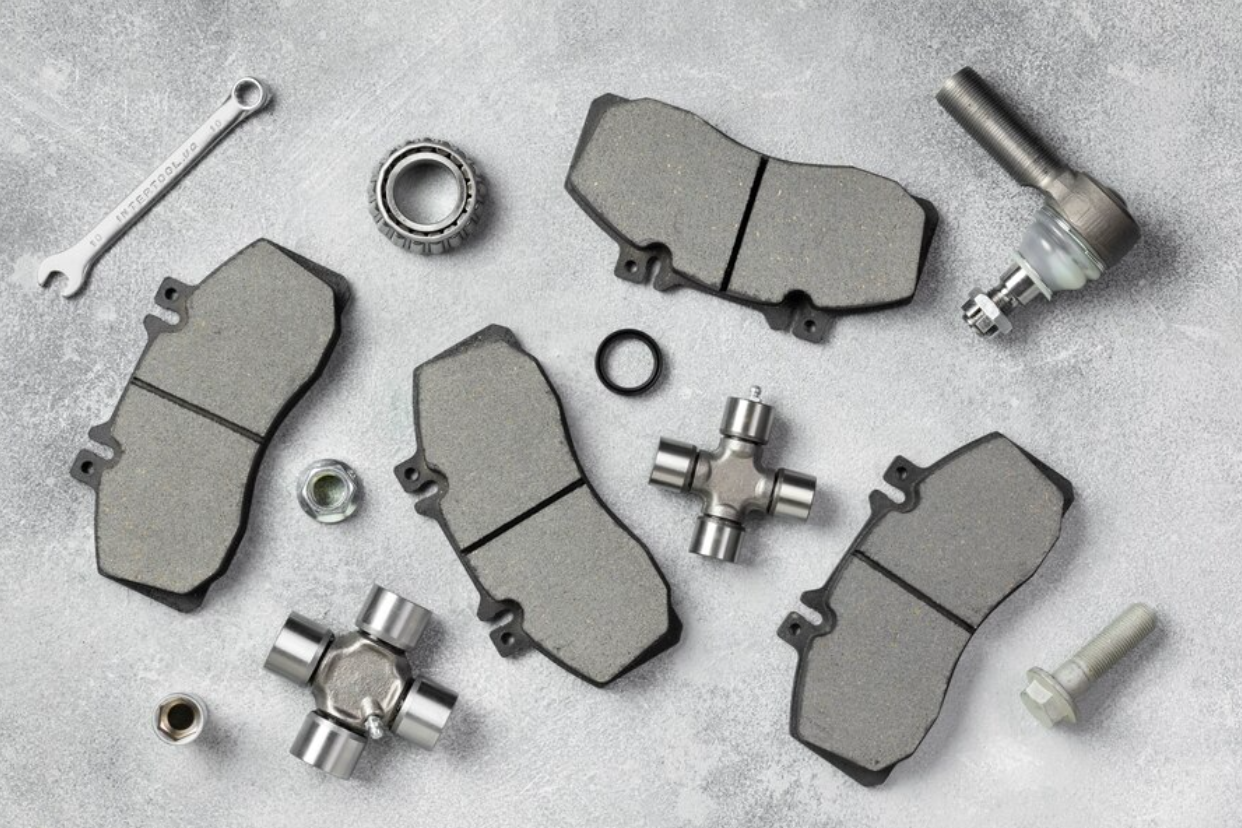

The demand for small parts is on the rise in various industries, including automotive, electronics, and consumer goods. A small injection molding machine provides the flexibility and efficiency needed to meet these demands without the overhead of larger machinery. The C-frame series from YIZUMI offers a compact and powerful solution for manufacturers looking to produce high-quality components.

Low Volume Manufacturing

One of the primary applications for a small injection machine is low volume manufacturing. Many businesses require a limited number of specialized parts, and investing in a large injection molding machine may not be feasible.

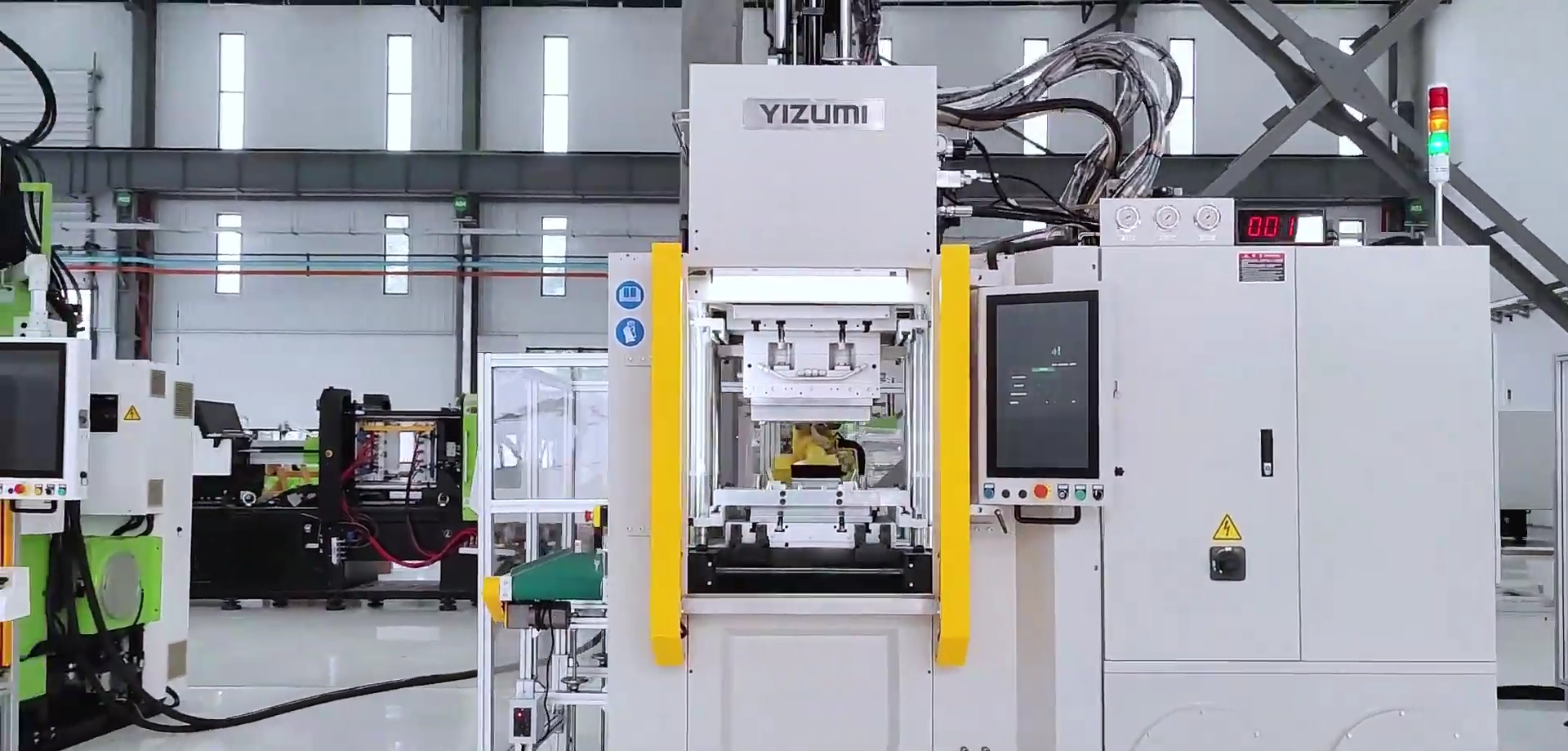

YIZUMI's C-frame series is designed specifically for such tasks, allowing manufacturers to create small, precise parts with inserts and profile jointing. With its compact footprint and energy-efficient design, it is ideal for businesses looking to optimize their production without compromising quality.

The C-frame structure, made from high-strength alloy steel, ensures long-term stability during production. This reliability is critical for low volume manufacturing, where consistency in output is essential. By choosing a small injection molding machine, businesses can maintain control over their production processes, allowing for rapid adjustments and improvements as needed.

Engineering Prototype, Research and Development

In the realm of engineering prototypes and R&D, the ability to quickly produce test parts is vital. A small injection molding machine can facilitate rapid prototyping, enabling engineers and designers to test their concepts in real-world conditions.

The modular design of YIZUMI's C-frame series allows for easy adjustments and adaptations, making it suitable for various materials such as EPDM, TPE, and LSR. This versatility is crucial for R&D teams, as they often work with a range of materials and designs.

Moreover, the ultra-high injection pressure capability of the C-frame series enables the production of specialized parts that may require precise specifications. By investing in a small injection machine, companies can streamline their development processes and bring products to market faster.

Bootstrap Entrepreneurs in a Small Business

For entrepreneurs starting a small business, having access to efficient and cost-effective manufacturing solutions is critical. A small injection molding machine allows entrepreneurs to produce their products without the heavy investment typically associated with larger machinery.

YIZUMI's C-frame series is particularly appealing to small business owners due to its energy-saving features. With up to 50% energy savings compared to traditional machines, entrepreneurs can reduce their operational costs while maintaining high-quality production standards.

Additionally, the user-friendly design of the C-frame series simplifies the operation and maintenance processes. This ease of use empowers entrepreneurs who may not have extensive manufacturing experience to produce their products effectively. By leveraging a small injection molding machine, these business owners can focus more on growth and innovation rather than getting bogged down by complex machinery.

Hobbyists / Engineers Alone

Hobbyists and independent engineers often seek out affordable, versatile equipment to support their projects. A small injection machine can serve as an invaluable tool for individuals looking to create unique, custom parts for their projects.

The compact design of YIZUMI's C-frame series makes it an ideal fit for smaller workshops or even home environments. Its modular capabilities allow hobbyists to experiment with different materials and designs without a significant financial investment.

Moreover, the ability to produce parts on-demand means that hobbyists can quickly adapt their projects to new ideas or improvements, enhancing their creativity and efficiency. With a small injection molding machine, engineers and hobbyists alike can take full control of their production processes and achieve their project goals more effectively.

Education

Educational institutions, especially those specializing in engineering and manufacturing, stand to gain immensely from the integration of a small injection molding machine into their academic programs. The C-frame series, in particular, serves as an invaluable educational tool, providing students with hands-on experience in the intricacies of injection molding. This practical exposure not only deepens their understanding of the manufacturing process but also offers insights that are crucial for their future careers.

By working with YIZUMI's C-frame series, students can delve into various critical aspects of the molding industry, including mold design, material selection, and the operational functions of molding machinery. This kind of practical knowledge is essential for equipping the next generation of engineers and manufacturers with the expertise they need to thrive in a fast-evolving industry.

Moreover, the energy-efficient and user-friendly design of the C-frame series allows educational institutions to demonstrate modern manufacturing techniques without incurring excessive operational costs. Incorporating a small injection molding machine into the curriculum not only enhances the learning experience but also ensures that students are well-prepared for the challenges of today's competitive job market. By offering such hands-on training, schools can effectively bridge the gap between theoretical knowledge and real-world application, fostering a new wave of skilled professionals ready to contribute to the manufacturing sector.

Conclusion

In conclusion, a small injection molding machine like YIZUMI's C-frame series offers significant advantages across various sectors. From low volume manufacturing to R&D, small businesses, hobbyists, and educational institutions, the versatility and efficiency of this machinery make it a wise investment.

With YIZUMI's commitment to quality and innovation, we provide manufacturers with the tools they need to excel in their production processes. By choosing a small injection machine, businesses and individuals can enhance their productivity while maintaining high standards of quality. If you want to experience more about the charm of molding equipment, please visit YIZUMI's website!