What Is Die Casting? Overview, Materials, Process, & Applications

Abstract:

Die casting is a cornerstone manufacturing process that delivers high-quality metal components with exceptional precision and efficiency. At its core, die casting involves forcing molten metal into a mold cavity under high pressure, producing durable parts with tight tolerances and complex geometries.

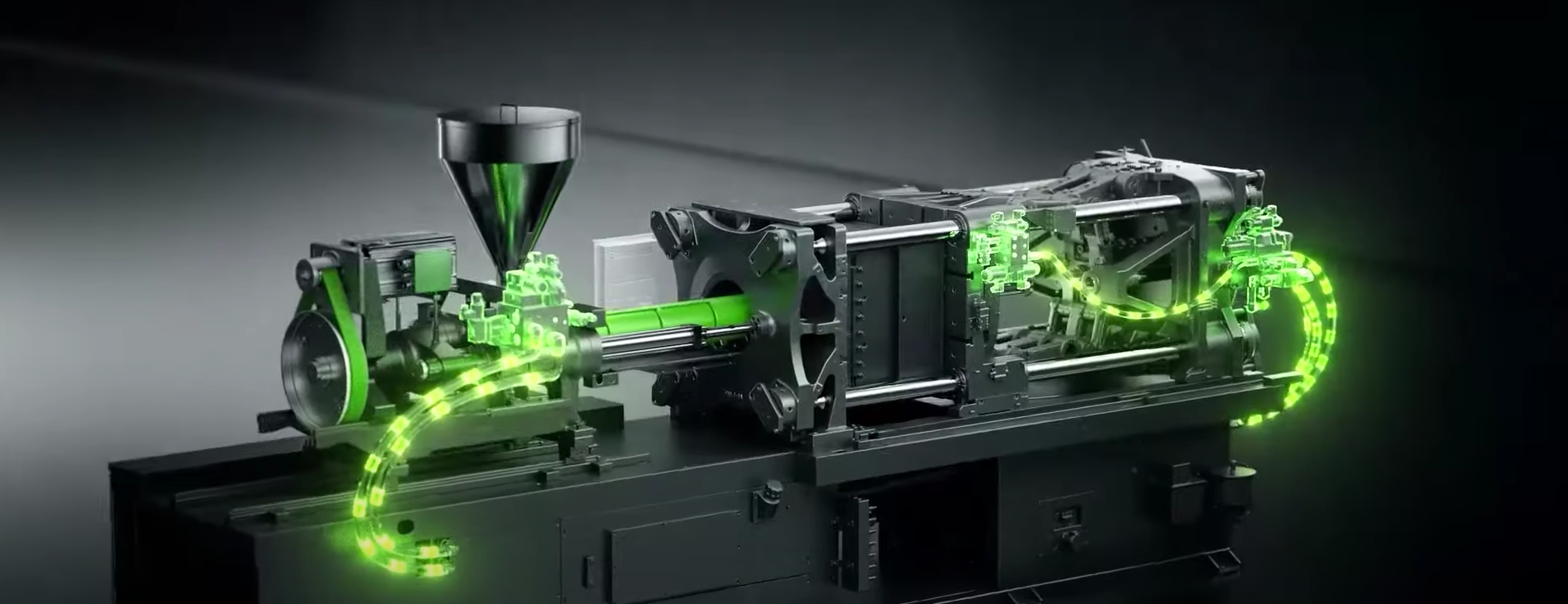

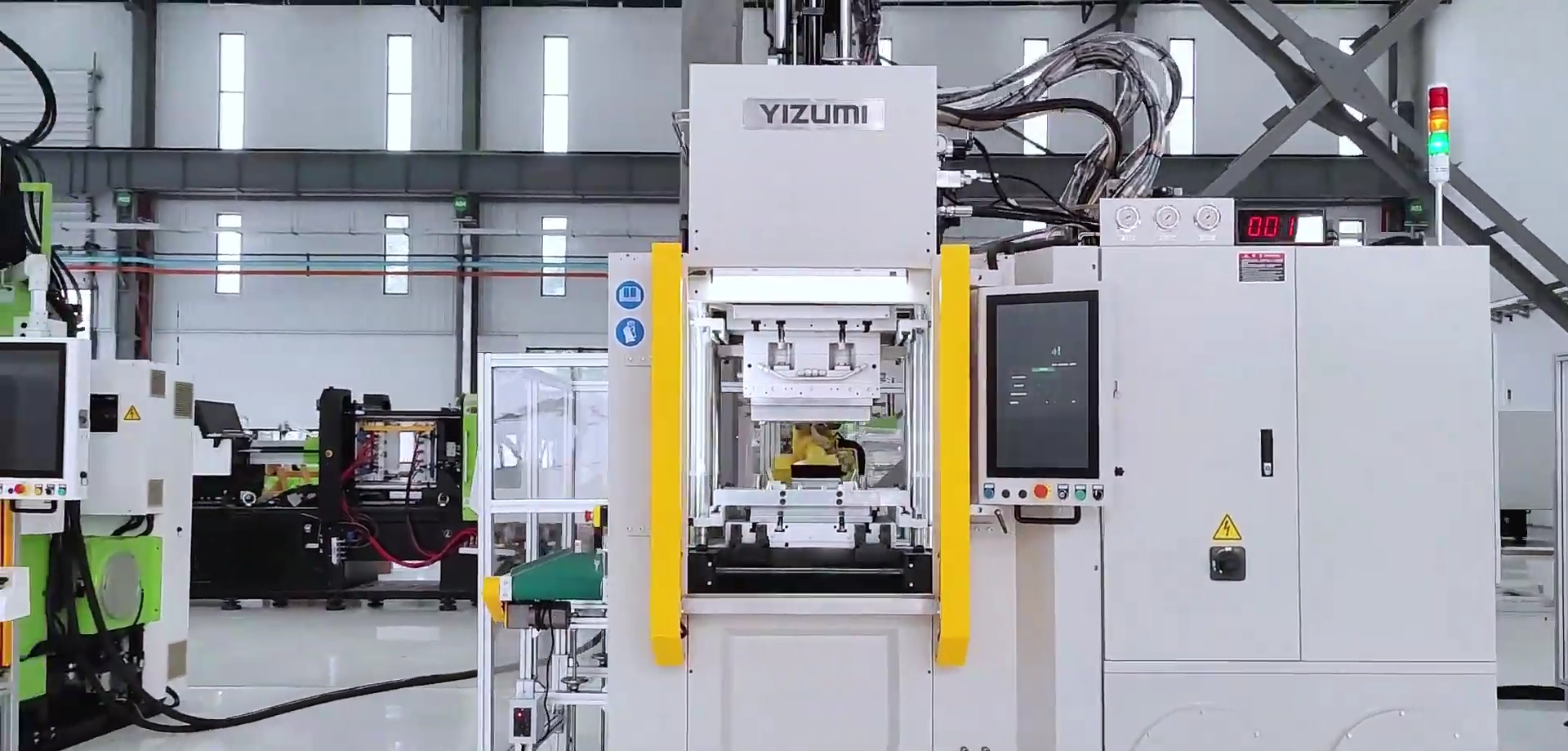

Die casting is a cornerstone manufacturing process that delivers high-quality metal components with exceptional precision and efficiency. At its core, die casting involves forcing molten metal into a mold cavity under high pressure, producing durable parts with tight tolerances and complex geometries. This article explores the fundamentals of die casting, its materials, process, applications, and the advanced capabilities of YIZUMI's HM Series High-performance Hot Chamber Die Casting Machine and HII-S Series High-end Cold Chamber Die Casting Machine (1000-5000T).

Die Casting Mold Overview

A die casting mold, also referred to simply as a die, is the core component of the die casting process, which is widely used to produce precise metal parts. The mold serves as the cavity into which molten metal is injected, shaping the material as it cools and solidifies. These molds are generally constructed from hardened tool steel or other high-performance alloys, carefully selected for their ability to withstand the harsh conditions of the casting process. The hardness and strength of the steel ensure that the mold can endure repeated use without warping, cracking, or losing its shape, which is crucial for maintaining consistent quality and precision in the cast parts.

The die casting mold is typically divided into two main parts: the fixed half and the movable half. The fixed half is stationary and contains the primary features and cavities that define the shape of the cast component. The movable half, as the name suggests, can open and close to allow for the injection of molten metal and the removal of the finished part. When the two halves are closed, they form a tight seal that ensures the molten metal fills the cavity precisely without leakage or distortion. After the metal solidifies, the movable half opens, and the part is ejected, typically with the help of ejector pins.

Die casting molds can incorporate cooling and ejector systems to improve efficiency. Precision in mold design is critical for ensuring the quality of the final product, which is why manufacturers like YIZUMI focus on integrating advanced die protection and intelligent clamping systems into their die casting machinery.

What Are the Types of Die Casting?

Die casting processes are classified primarily into two types: hot chamber and cold chamber, each with distinct applications and advantages.

Hot Chamber Die Casting

Hot chamber die casting is ideal for materials with low melting points, such as zinc, magnesium, and lead. YIZUMI’s HM Series High-performance Hot Chamber Die Casting Machine excels in this category.

· High Efficiency: The HM Series features an optimized injection system with two-stage control, ensuring precise and stable production for industries like 3C, bathroom hardware, and home furnishing.

· User-Friendly Design: Equipped with a Siemens PLC control system and an intuitive human-machine interface, it simplifies operation and reduces setup times.

· Enhanced Productivity: The high-speed toggle system achieves shorter cycle times while maintaining consistent quality, making it the ideal choice for high-volume production.

Cold Chamber Die Casting

Cold chamber die casting is used for materials with higher melting points, such as aluminum, brass, and copper alloys. YIZUMI’s HII-S Series High-end Cold Chamber Die Casting Machine (1000-5000T) sets the benchmark in this segment.

· Unmatched Precision: The HII-S Series offers improved casting accuracy and reduced pressure build-up time, meeting the demands of large-scale, high-quality production.

· Energy Efficiency: Its advanced hydraulic drive system ensures faster cycle times with minimal energy consumption.

· Durable Design: Built for longevity, the re-engineered clamping and injection units enhance machine stability and reduce maintenance costs.

What Are the Steps Involved in Die Casting?

Die casting involves several key steps that ensure the production of high-quality components:

1. Preparation: The mold is cleaned and lubricated to facilitate the smooth release of the cast part.

2. Molten Metal Injection: In hot chamber machines, the metal is melted within the machine itself, while in cold chamber machines, it is melted externally and transferred to the injection chamber.

3. Filling: Molten metal is injected into the mold cavity at high pressure, ensuring precise filling of intricate details.

4. Cooling: The metal solidifies within the mold. Cooling systems integrated into YIZUMI machines ensure uniform solidification.

5. Ejection: The cast part is ejected from the mold. Intelligent die clamping systems in YIZUMI’s machines reduce flash and protect the mold during this process.

6. Trimming and Finishing: Excess material is removed, and the part undergoes additional finishing processes as required.

What Are the Most Suitable Materials for Die Casting?

Die casting is compatible with a variety of metals, including:

· Zinc: Ideal for hot chamber die casting due to its low melting point and high ductility.

· Magnesium: Lightweight and corrosion-resistant, suitable for automotive and aerospace applications.

· Aluminum: Known for its strength-to-weight ratio, commonly used in cold chamber processes for structural components.

· Brass: Offers excellent thermal conductivity and durability, often used for electrical components.

YIZUMI’s die casting machines are engineered to handle these materials with exceptional precision and efficiency.

Applications of Die Casting

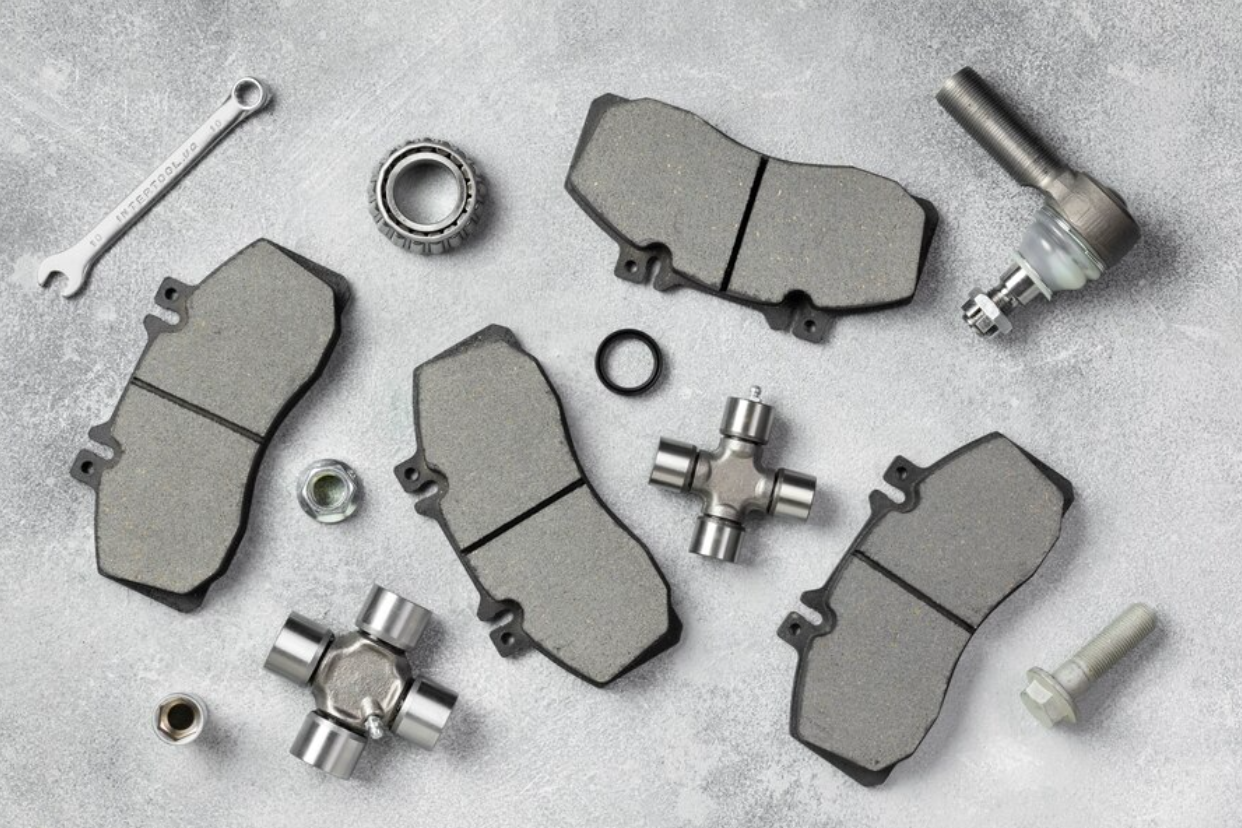

Die casting is used in a wide range of industries, including:

· Automotive: Manufacturing engine parts, transmission cases, and wheels.

· Consumer Electronics: Producing casings for smartphones, laptops, and other devices.

· Industrial Equipment: Creating housings, brackets, and other components.

· Household Appliances: Fabricating parts for refrigerators, washing machines, and more.

YIZUMI’s HM Series and HII-S Series cater to these diverse applications by offering versatility and reliability across multiple production environments.

Advantages and Disadvantages of Die Casting

Advantages

· High Precision: Produces components with tight tolerances and complex shapes.

· Efficiency: Shorter cycle times and high-volume production capabilities.

· Surface Quality: Smooth finishes reduce the need for additional machining.

· Material Utilization: Minimal waste compared to other manufacturing methods.

Disadvantages

· Initial Cost: High upfront cost for molds and equipment.

· Material Limitations: Not suitable for ferrous metals.

· Size Constraints: Larger parts may require multiple molds or processes.

Despite these challenges, YIZUMI’s advanced die casting machinery mitigates many of these drawbacks through intelligent design and innovative technologies.

Conclusion

Die casting remains an indispensable process in modern manufacturing, offering unparalleled precision, efficiency, and versatility. Whether it’s hot chamber or cold chamber die casting, YIZUMI’s machines provide cutting-edge solutions tailored to meet the diverse needs of industries worldwide.

The HM Series High-performance Hot Chamber Die Casting Machine and HII-S Series High-end Cold Chamber Die Casting Machine (1000-5000T) represent the pinnacle of die casting technology, combining energy efficiency, precision, and durability.

With our expertise in die casting and overall equipment solutions, YIZUMI continues to lead the way in empowering manufacturers to achieve their goals.