Sustainable Production by YIZUMI Machines

Abstract:

Sustainable practices support ecological, human, and economic health and vitality

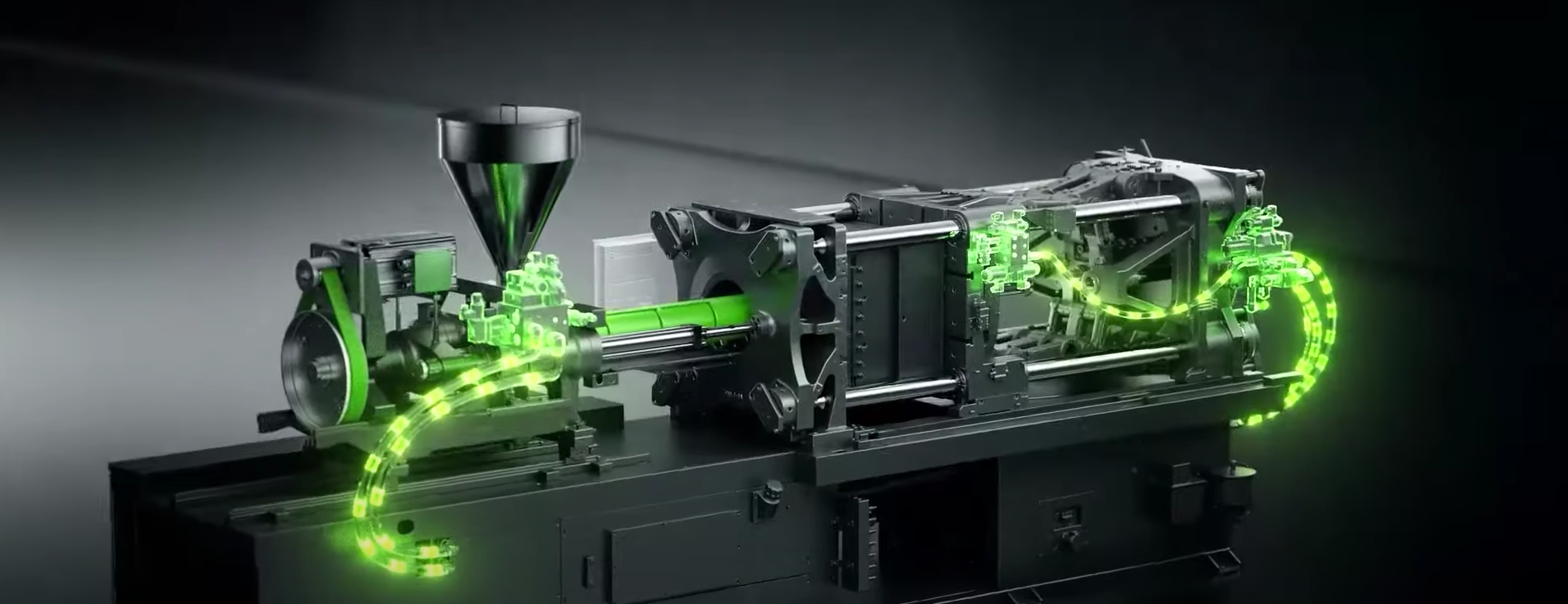

In the modern manufacturing landscape, sustainability has become a cornerstone of successful production strategies. As industries worldwide embrace eco-friendly practices, YIZUMI stands at the forefront, offering innovative machinery that supports sustainable production. One of our standout products, the Air Spring Molding Machine, exemplifies how advanced technology can meet both environmental and efficiency goals. In this article, we'll explore the sustainable production practices enabled by YIZUMI machines, focusing on our Air Spring Molding Machine and its benefits in rubber injection molding.

Understanding the Role of Machines in Sustainable Production

Manufacturers today face the dual challenge of increasing production efficiency while minimizing their environmental footprint. This is where sustainable production practices come into play. Sustainable production involves utilizing resources efficiently, reducing waste, and minimizing energy consumption. At YIZUMI, we understand that our machines play a crucial role in achieving these goals. Our rubber injection molding machines, particularly the Air Spring Molding Machine, are designed to enhance productivity while promoting eco-friendliness.

The Air Spring Molding Machine: A Sustainable Solution

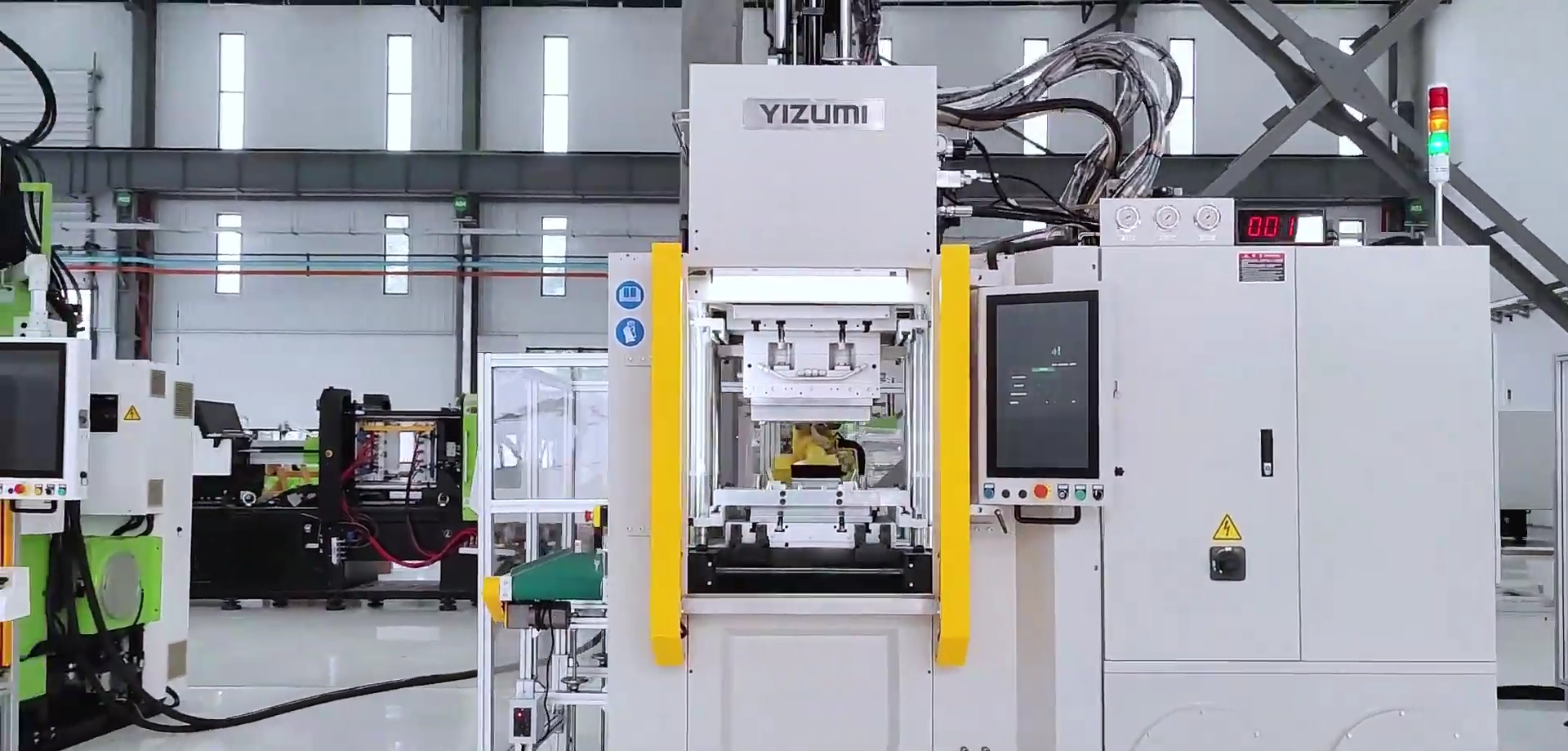

The Air Spring Molding Machine is a prime example of YIZUMI's commitment to sustainable production. Designed in line with the advanced molding processes and performance requirements of European air springs, this machine is engineered for efficiency and precision. Here are some of its key features that contribute to sustainable production:

Four-Column Clamping Structure

The Air Spring Molding Machine features a robust four-column clamping structure that provides a large clamping stroke. This design allows for the installation of molds with a height range of 400 to 1100 mm, accommodating various product designs without compromising on quality. By enhancing mold versatility, we reduce the need for multiple machines, thereby saving resources and space.

High-Temperature Control Accuracy

One of the most significant challenges in rubber injection molding is maintaining consistent quality during the vulcanization process. Our machine achieves high-temperature control accuracy, with steam temperature control precise to ±2°C. This accuracy ensures that the vulcanized parts meet strict quality standards, reducing waste from defective products and rework.

Advanced Gas Control System

Sustainability is not just about energy efficiency; it also involves precise control of processes. Our Air Spring Molding Machine incorporates an advanced gas control system that enables precise management of high and low-pressure nitrogen during forming stages. This technology allows for optimal performance based on the specific requirements of different products, thereby enhancing the overall efficiency of the production process.

Eco-Friendly Features of YIZUMI Machines

Sustainable production isn't solely about the machines themselves; it's also about how they interact with the environment. YIZUMI machines, including the Air Spring Molding Machine, are designed with eco-friendliness in mind:

Free Programming with Siemens Control System

Our machines are equipped with a Siemens control system that allows users to self-program and compile production sequences according to their process requirements. This flexibility helps in optimizing production runs and reduces material waste, as manufacturers can adjust settings on-the-fly to meet changing demands without overproducing.

Safety and Emission Controls

YIZUMI is dedicated to meeting stringent safety standards. The Air Spring Molding Machine includes pneumatic doors and all-around safety guards that protect operators while minimizing emissions during vulcanization. By addressing gas emissions from the production process, we not only comply with environmental regulations but also contribute to cleaner production methods.

The Advantages of Rubber Injection Molding with YIZUMI

Rubber injection molding is a complex process that requires precision and efficiency. Our Air Spring Molding Machine is equipped with cutting-edge technology that enhances production capabilities, making it the preferred choice for manufacturers. Here are some advantages of using YIZUMI machines for rubber injection molding:

Enhanced Production Efficiency

With features like precise temperature control and an advanced gas control system, our machines enable faster cycle times and higher production rates. This translates to increased productivity without compromising on product quality. Manufacturers can achieve more in less time, which is crucial in today's fast-paced market.

Consistent Quality

Quality consistency is essential in manufacturing, particularly in industries where safety and reliability are paramount. The high control accuracy of the Air Spring Molding Machine ensures that every product meets the required specifications, reducing defects and enhancing customer satisfaction.

Energy Efficiency

YIZUMI machines are designed to operate with maximum energy efficiency. By reducing energy consumption during the molding process, we help manufacturers lower their operational costs while also minimizing their environmental impact. Our machines can use up to 30-80% less energy than conventional hydraulic machines, making them a sustainable choice for rubber injection molding.

Tips for Achieving Sustainable Production with YIZUMI

To fully leverage the benefits of our Air Spring Molding Machine and promote sustainable practices, consider the following tips:

Invest in Quality Machines: Choose high-quality machinery like YIZUMI's rubber injection molding machines that offer advanced features for efficiency and sustainability.

Regular Maintenance: Ensure your machines are regularly maintained to operate at peak efficiency, which can help prevent energy waste and reduce downtime.

Optimize Production Settings: Utilize the free programming capabilities of our Siemens control system to adapt production runs to meet demand without overproduction.

Monitor Resource Usage: Keep track of material and energy usage to identify areas where improvements can be made.

Embrace Eco-Friendly Practices: Incorporate eco-friendly practices into your production processes, such as recycling waste materials and minimizing emissions.

Conclusion

Sustainable production is not merely a passing trend; it is an imperative for the future of the manufacturing industry. As global awareness of environmental issues grows, the demand for eco-friendly practices in production becomes increasingly vital.

At YIZUMI, we recognize this need and are dedicated to developing machines that not only boost productivity but also align with sustainable practices. Our Air Spring Molding Machine is a prime example of this commitment, showcasing cutting-edge technology and features specifically designed to enhance operational efficiency while minimizing environmental impact. This innovative machine integrates advanced capabilities that allow manufacturers to optimize their production processes, resulting in lower energy consumption and reduced waste. By employing energy-efficient systems and utilizing materials that are less harmful to the environment, our Air Spring Molding Machine enables businesses to produce high-quality products while adhering to eco-friendly standards. Investing in YIZUMI machines represents a significant step for manufacturers aiming to achieve their sustainability goals.

By incorporating our technology into their operations, companies not only improve their productivity and profitability but also contribute to a more sustainable future for the planet. In a world where consumers increasingly value sustainability, embracing environmentally responsible manufacturing practices is not just beneficial—it's essential for long-term success. Through our commitment to innovation and sustainability, YIZUMI empowers manufacturers to lead the charge towards a greener and more responsible manufacturing landscape. If you want to experience more about the charm of molding equipment, please visit YIZUMI's website!