Revolutionizing Small-Scale Manufacturing: Desktop Moulding

Abstract:

Desktop moulding, also known as benchtop injection moulding, offers a compact and cost-effective alternative to traditional industrial machines. These smaller-scale machines are designed to fit on a workbench, making them ideal for limited spaces. Desktop moulding machines maintain the precision and capabilities of their larger counterparts while providing the flexibility and affordability needed by SMEs.

In the ever-evolving world of manufacturing, small and medium enterprises (SMEs) face unique challenges. Limited resources, space constraints, and the need for high precision and efficiency are some of the hurdles they must overcome. Enter desktop moulding, a transformative technology that is revolutionizing small-scale manufacturing. This article explores the benefits, applications, and innovations of desktop moulding, with a special focus on YIZUMI’s advanced solutions that enable companies to achieve precision and efficiency on a compact scale.

Challenges for Small and Medium Enterprises

SMEs often struggle with the high costs and complexities associated with traditional injection moulding processes. Large industrial machines are expensive, require significant space, and demand substantial energy and maintenance. These factors can be prohibitive for smaller operations looking to produce high-quality components efficiently. Additionally, SMEs need flexible solutions that can adapt to varying production needs without compromising on precision or quality.

Introduction to Desktop Moulding

Desktop moulding, also known as benchtop injection moulding, offers a compact and cost-effective alternative to traditional industrial machines. These smaller-scale machines are designed to fit on a workbench, making them ideal for limited spaces. Desktop moulding machines maintain the precision and capabilities of their larger counterparts while providing the flexibility and affordability needed by SMEs.

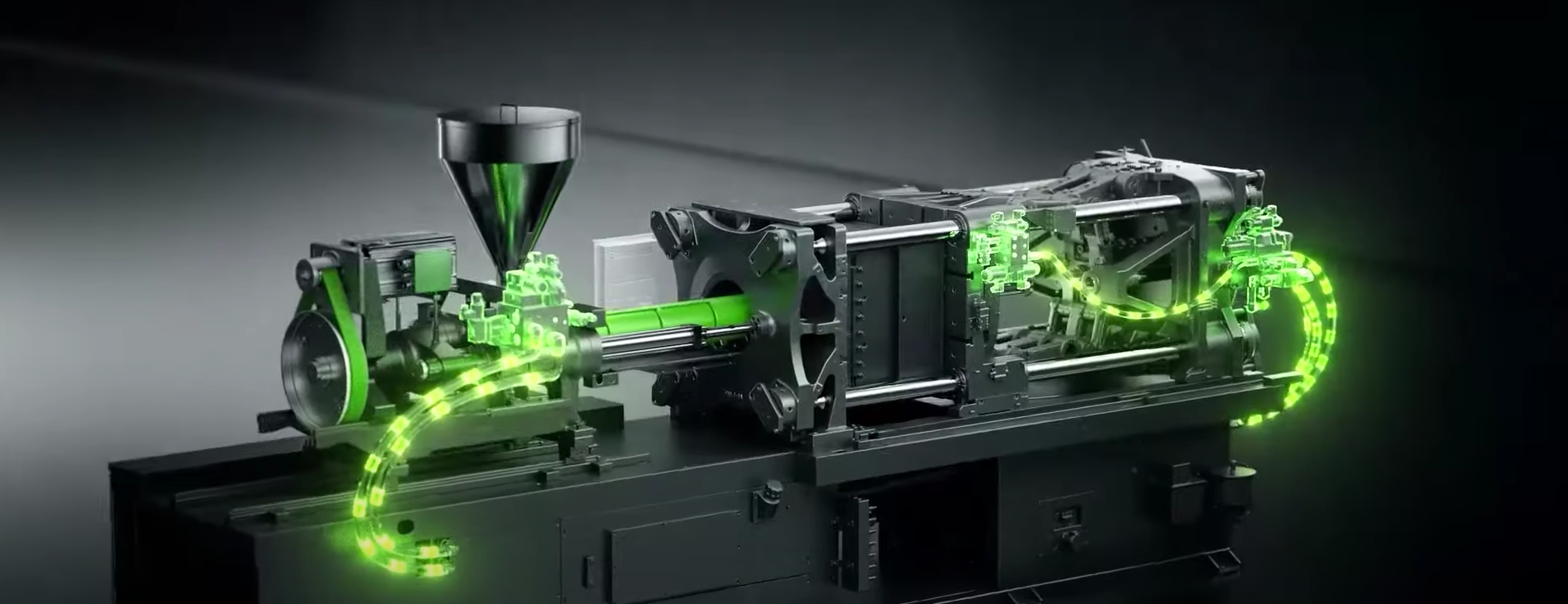

Desktop moulding machines work on the same principles as traditional injection moulding. They melt plastic pellets and inject the molten material into a mould cavity, where it cools and solidifies into the desired shape. The primary difference lies in the size and scale of the machines, making them suitable for small to medium production runs and prototyping.

Applications Across Small-Scale Manufacturing

Desktop moulding machines find extensive applications across diverse industries, offering significant advantages to small-scale manufacturing endeavors. These versatile machines cater to a broad spectrum of needs, enabling efficient production in contexts where limited quantities or specialized components are required. Their utilization spans across sectors such as product development, rapid prototyping, customized manufacturing, and small batch production. This accessibility and adaptability make desktop moulding a pivotal technology for enhancing innovation and accelerating production timelines in modern industry settings.

Prototyping: Desktop moulding machines provide an ideal platform for creating prototypes, enabling designers and engineers to iterate and perfect their designs before moving to full-scale production. This iterative process helps in identifying and resolving potential issues early, thereby saving time and costs associated with later-stage modifications.

Custom Parts: Small and medium-sized enterprises (SMEs) can leverage desktop moulding to produce custom parts internally. By reducing reliance on external suppliers, businesses can maintain greater control over production schedules and quality standards. This capability also facilitates shorter lead times, crucial for meeting dynamic market demands and customer preferences.

Short Production Runs: Desktop moulding is particularly advantageous for small production runs where traditional large-scale machinery might be economically impractical. These machines offer a cost-effective solution, minimizing overhead costs and operational complexities associated with larger equipment setups. This flexibility allows businesses to respond swiftly to market opportunities and efficiently manage inventory levels.

Startups: Startups benefit significantly from the accessibility and versatility of desktop moulding machines. With lower initial investment costs compared to larger industrial equipment, startups can initiate production quickly and test their product concepts with minimal financial risk. This rapid prototyping capability empowers startups to refine their offerings based on early market feedback, accelerating their time-to-market and enhancing competitiveness in their respective industries

Advantages of YIZUMI's Desktop Moulding Solutions

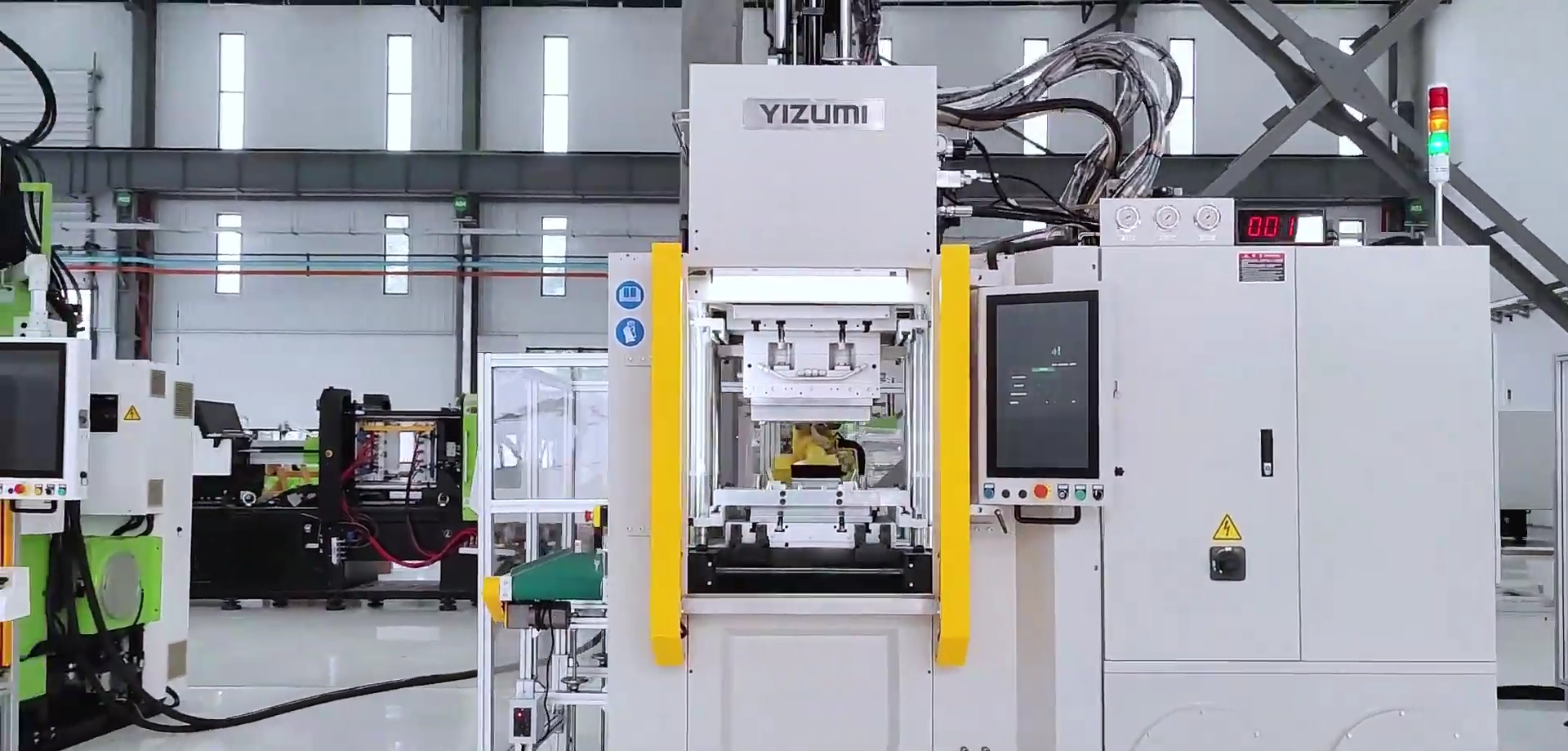

YIZUMI, a leader in injection moulding technology, offers advanced desktop moulding solutions that are transforming small-scale manufacturing. One notable product is the YIZUMI SpaceA S-Line Industrial Pellet 3D Printing.

Cost Efficiency: The YIZUMI SpaceA S-Line offers SMEs a breakthrough in small batch industrial manufacturing by utilizing common thermoplastic pellets for injection molding. This approach significantly reduces costs compared to specialized 3D printing materials, making advanced manufacturing processes more accessible even for SMEs with limited budgets. By leveraging widely available materials, businesses can lower production expenses without compromising on quality, thereby enhancing their competitiveness in the market.

High Surface Quality and Dimensional Accuracy: Through the integration of CNC machining automation and insert molding processes, the SpaceA S-Line ensures superior surface quality and precise dimensional accuracy. This capability is crucial for SMEs striving to maintain consistent product excellence and meet rigorous industry standards. By achieving high levels of precision in manufacturing, businesses can deliver products that meet or exceed customer expectations, fostering trust and satisfaction in their brand.

3D Reinforcement: The machine's capability to create complex product structures and 3-dimensional reinforcement using a 6-axis robot empowers SMEs to produce intricate parts and components efficiently. This feature is particularly beneficial for industries requiring robust and durable products, such as automotive or aerospace sectors. By enabling the production of sophisticated designs that are difficult or expensive with traditional methods, SMEs can expand their product offerings and explore new market opportunities.

High Output: Equipped with a screw extruder capable of achieving high throughput (>500g/h), the SpaceA S-Line ensures efficient production rates that cater to the needs of SMEs. This high output capacity supports faster manufacturing cycles and shorter turnaround times, enhancing overall operational efficiency. By maximizing production throughput, businesses can meet deadlines more effectively and scale their operations to meet increasing demand, thereby improving profitability and competitiveness.

Modular Design for Flexibility: The modular design of the SpaceA S-Line allows for flexible integration with various processes such as injection molding and image recognition. This versatility enables SMEs to adapt the machine to different production requirements and workflows, optimizing production efficiency and versatility. By customizing the machine's configuration to suit specific manufacturing needs, businesses can enhance workflow efficiency, minimize downtime, and streamline operations, ultimately driving productivity and profitability.

Conclusion

Desktop moulding is revolutionizing small-scale manufacturing by offering a compact, cost-effective, and precise solution for producing high-quality components. YIZUMI's advanced desktop moulding solutions, such as the DP Series Desktop Injection Moulding Machine, are at the forefront of this transformation, providing SMEs with the tools they need to compete and thrive in the modern manufacturing landscape.

By leveraging the benefits of desktop moulding, small and medium enterprises can overcome traditional manufacturing challenges, streamline their production processes, and bring innovative products to market with greater efficiency and speed. As the demand for flexible and affordable manufacturing solutions continues to grow, desktop moulding stands out as a game-changing technology that is shaping the future of small-scale production.

For more information on YIZUMI’s desktop moulding solutions and how they can enhance your manufacturing capabilities, visit YIZUMI’s official website. Embrace the future of small-scale manufacturing with advanced desktop moulding and discover the difference it can make in your production efficiency and product quality.