Improving efficiency and bringing innovation: advanced stacked mold design

Abstract:

YIZUMI's FF Series Electric Injection Molding Machine sets a new standard with its advanced stacked mold design, surpassing traditional machines by integrating seamless automation and intellectualization. This innovation ensures superior quality consistency and operational efficiency. With clamping forces ranging from 900 to 13,800 kN, the FF Series excels in molding applications requiring enhanced thickness, precision, and complexity.

Innovation and efficiency are key drivers of success in today's fast-moving manufacturing industry. One technological advancement that has significantly impacted the sector is stack mould design. This innovative approach uses multi-layered moulds to produce complex parts with high efficiency and precision. By intelligently combining different materials, stack mould design allows for targeted improvements in component properties, making it a crucial tool for modern manufacturers. This article explores the fundamentals of stack mould design, its benefits, applications, and best practices for maintaining high standards.

Understanding Stack Mould Design

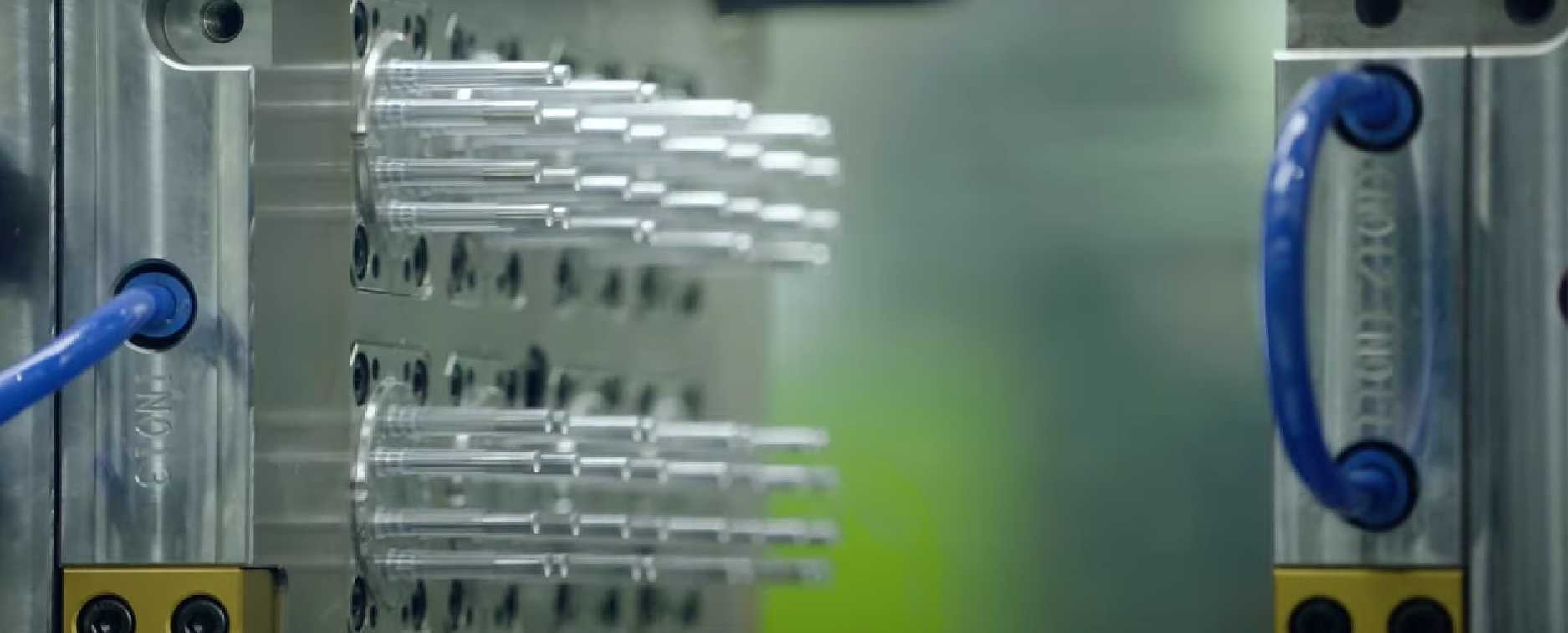

Stack mould design involves the use of multi-layered moulds arranged in a vertical stack, allowing for the simultaneous production of multiple parts within a single cycle. This design essentially doubles or triples the output without requiring additional machines or increasing the footprint of the manufacturing setup. The core concept revolves around increasing the productivity of injection moulding processes while maintaining, or even enhancing, the quality and precision of the produced parts.

In a typical stack mould, multiple mould plates are stacked one above the other, with each plate containing cavities for the parts to be molded. The mould opens and closes as a single unit, allowing for the injection of material into all cavities simultaneously. This setup significantly boosts production efficiency and is especially beneficial for high-volume manufacturing.

Improving Production Efficiency with Stack Mould Design

One of the primary advantages of stack mould design is its ability to enhance production efficiency. By using a stack mould, manufacturers can effectively double or triple their output without the need for additional machines or floor space. This not only reduces capital expenditure but also lowers operating costs.

YIZUMI’s Advanced Stack Mould Solution

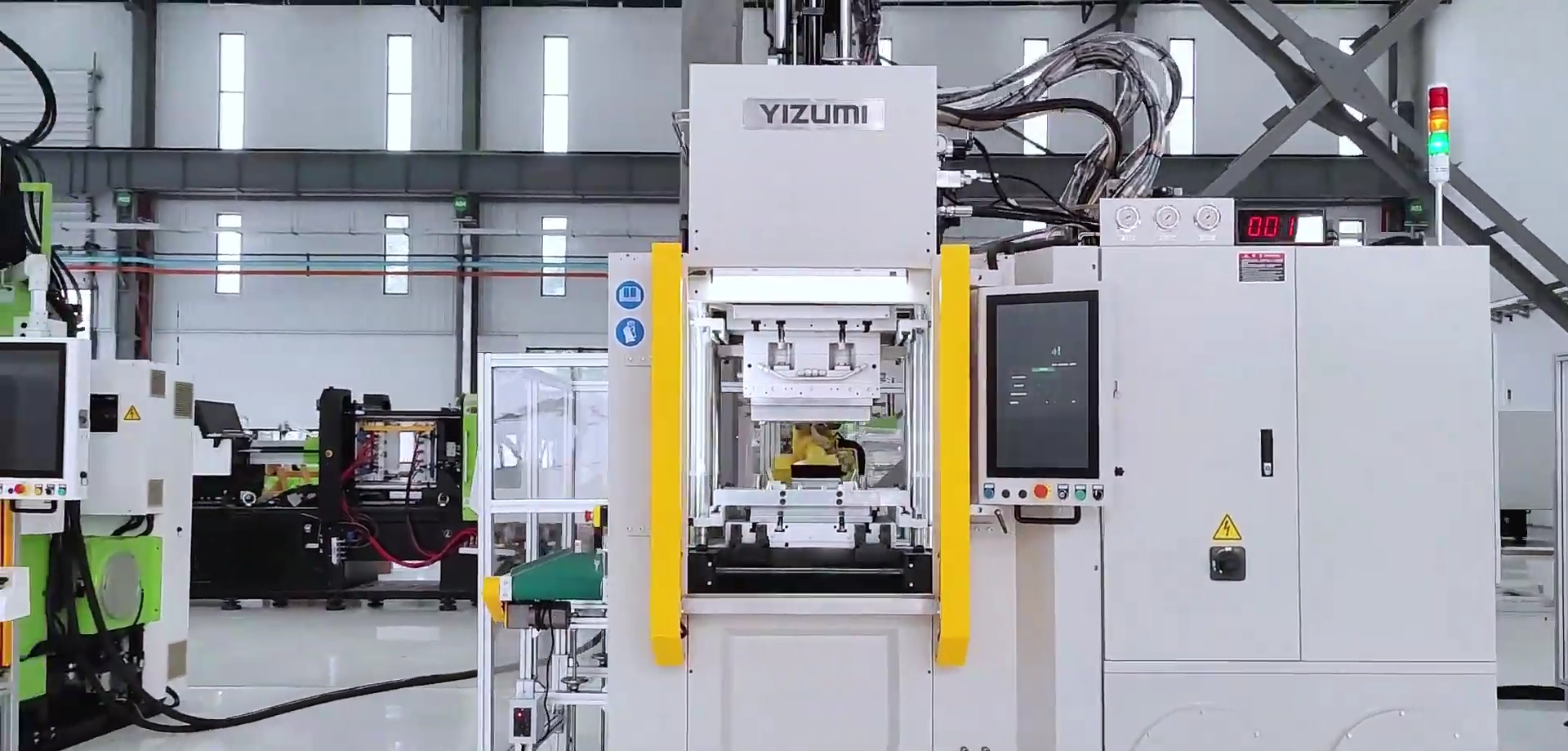

YIZUMI, a leader in injection moulding technology, offers an advanced stack mould solution designed to maximize efficiency and precision.

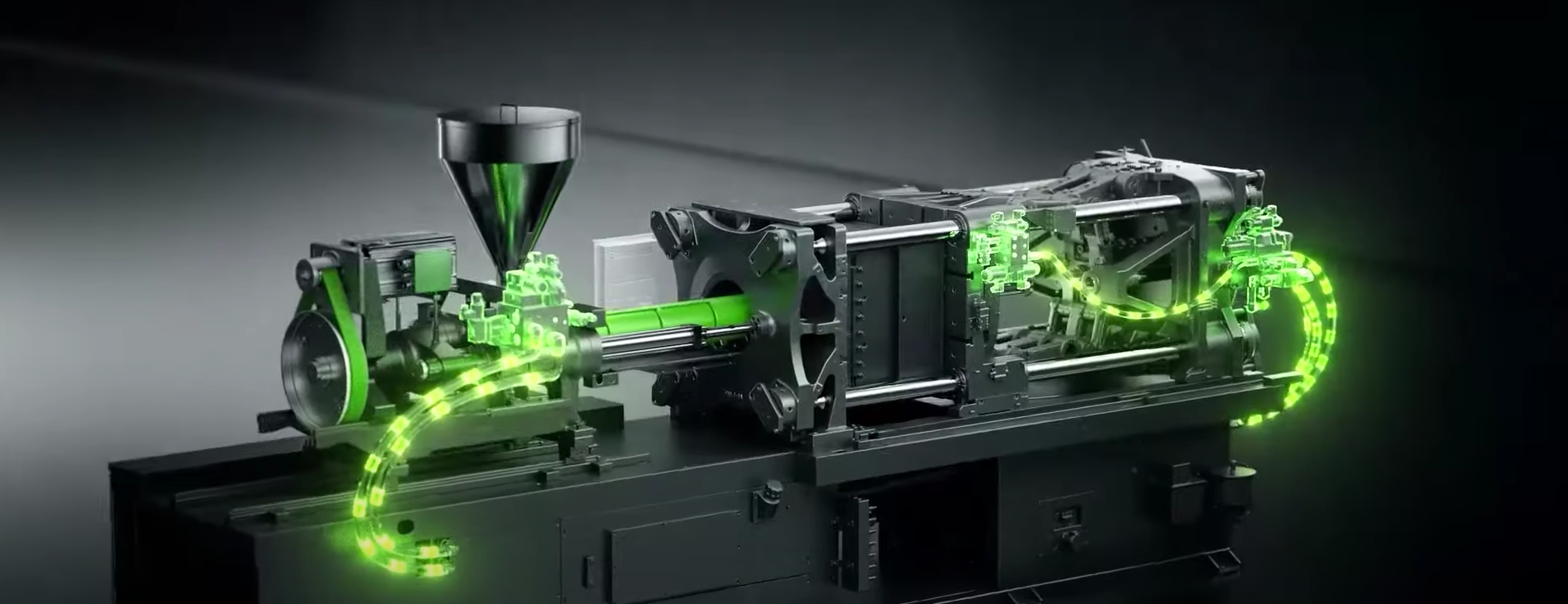

YIZUMI's FF Series Electric Injection Molding Machine sets a new standard with its advanced stacked mold design, surpassing traditional machines by integrating seamless automation and intellectualization. This innovation ensures superior quality consistency and operational efficiency. With clamping forces ranging from 900 to 13,800 kN, the FF Series excels in molding applications requiring enhanced thickness, precision, and complexity.

Key features include a dual-cylinder parallel ejection design for uniform mold release force and precise ejection positioning within 0.2mm, crucial for achieving high product accuracy and repeatability. The machine utilizes High Stability TBF technology to maintain operational reliability and incorporates a unique "SMART" mold protection feature for enhanced safety and mold longevity.

The FF Series also employs Servo Direct Control (SDC) technology, employing four independent servo motors to control injection, plasticizing, clamping, and ejection. This allows for faster feedback, responsive control, and precise adjustments in speed, position, and pressure, meeting the stringent demands of high-precision manufacturing.

Applications of Stack Mould Design

Automotive: In the automotive industry, stack moulds are used to produce components such as dashboards, door panels, and other interior parts. The high efficiency of stack moulds meets the demand for large quantities of precision parts.

Packaging: For the packaging industry, stack moulds are ideal for producing containers, caps, and closures in high volumes. The ability to produce multiple parts in a single cycle enhances productivity.

Consumer Goods: The consumer goods sector benefits from stack mould design for products such as household items, toys, and electronics. The precision and efficiency of stack moulds ensure high-quality output.

Medical Devices: Stack moulds are used in the medical field to produce components like syringes, vial caps, and other critical medical parts. The precision of stack moulds ensures that all components meet stringent quality standards.

Best Practices and Tips for Maintaining High Standards

To achieve the best results with stack mold design, manufacturers should adhere to several critical best practices.

-Regular maintenance of stack molds is critical to ensure optimal performance and longevity. This involves scheduling routine inspections to check for any signs of wear, damage, or corrosion. Cleaning the mold surfaces regularly helps prevent buildup of contaminants that could affect part quality. Lubrication of moving parts such as slides, lifters, and ejector pins ensures smooth operation and extends the life of these components. By addressing issues promptly and proactively maintaining stack molds, manufacturers can minimize downtime and production interruptions.

-Implementing stringent quality control measures is essential to uphold the integrity of parts produced by stack molds. This includes conducting regular inspections of molded parts to check for defects such as flash, sink marks, or dimensional inaccuracies. Testing can involve measurements, visual inspections, and functional tests to verify that parts meet specified requirements. By maintaining high standards of quality control, manufacturers can ensure consistency in part quality and customer satisfaction.

-Comprehensive training programs for operators are crucial to ensure they have the knowledge and skills required to operate and maintain stack molds effectively. Training should cover mold setup, operation procedures, troubleshooting common issues, and proper maintenance practices. Well-trained operators can identify potential problems early, perform routine maintenance tasks correctly, and respond efficiently to issues that arise during production. Continuous training also keeps operators updated on new technologies and best practices, enhancing overall efficiency and reducing errors.

-The quality of materials used in mold construction directly impacts durability, performance, and longevity. Choosing high-quality materials, such as tool steels with excellent wear resistance and heat treatment capabilities, ensures that stack molds can withstand the rigors of high-volume production. High-quality materials also contribute to maintaining dimensional stability and minimizing mold maintenance requirements over time. Investing in superior materials upfront can result in lower long-term maintenance costs and higher overall productivity.

-Collaborating with manufacturers like YIZUMI to customize stack mold solutions tailored to specific production needs offers several advantages. Customization allows for the optimization of mold design to achieve the desired part geometry, cycle time reduction, and enhanced part quality. Manufacturers can work closely with mold suppliers to incorporate features such as specialized cooling channels for improved heat dissipation, ergonomic designs for easier maintenance access, and advanced automation for increased productivity. Customized stack mold solutions are designed to maximize efficiency and quality while addressing unique production challenges effectively.

Conclusion

Stack mould design is revolutionizing the manufacturing industry by significantly improving production efficiency and enabling the creation of complex parts with high precision. YIZUMI’s advanced stack mould solutions exemplify the benefits of this innovative approach, offering manufacturers robust, efficient, and customizable options for a wide range of applications. By understanding the fundamentals of stack mould design and implementing best practices, manufacturers can achieve higher productivity, reduced costs, and superior quality in their production processes.

For more information on YIZUMI’s stack mould solutions and how they can enhance your manufacturing capabilities, visit YIZUMI’s official website. Embrace the future of manufacturing with advanced stack mould design and discover the difference it can make in your production efficiency and product quality.