Innovative Medical Device Production Using Rubber Injection Molding

Abstract:

Rubber Injection Molding is at the forefront of innovation in medical device manufacturing, offering precise and reliable solutions for complex healthcare needs. This article explores how this advanced technology is reshaping the production landscape, highlighting its benefits, real-world applications, and future prospects within the healthcare industry. Discover how rubber injection molding is driving efficiency, quality, and innovation in creating essential medical components critical to modern healthcare advancements.

In the ever-evolving field of medical device manufacturing, precision and reliability are paramount. As healthcare demands grow increasingly complex, innovative manufacturing techniques like rubber injection molding are stepping up to meet these challenges. This article explores how rubber injection molding is revolutionizing the production of medical devices, offering insights into its benefits, applications, and future prospects within the healthcare industry.

Introduction to Rubber Injection Molding

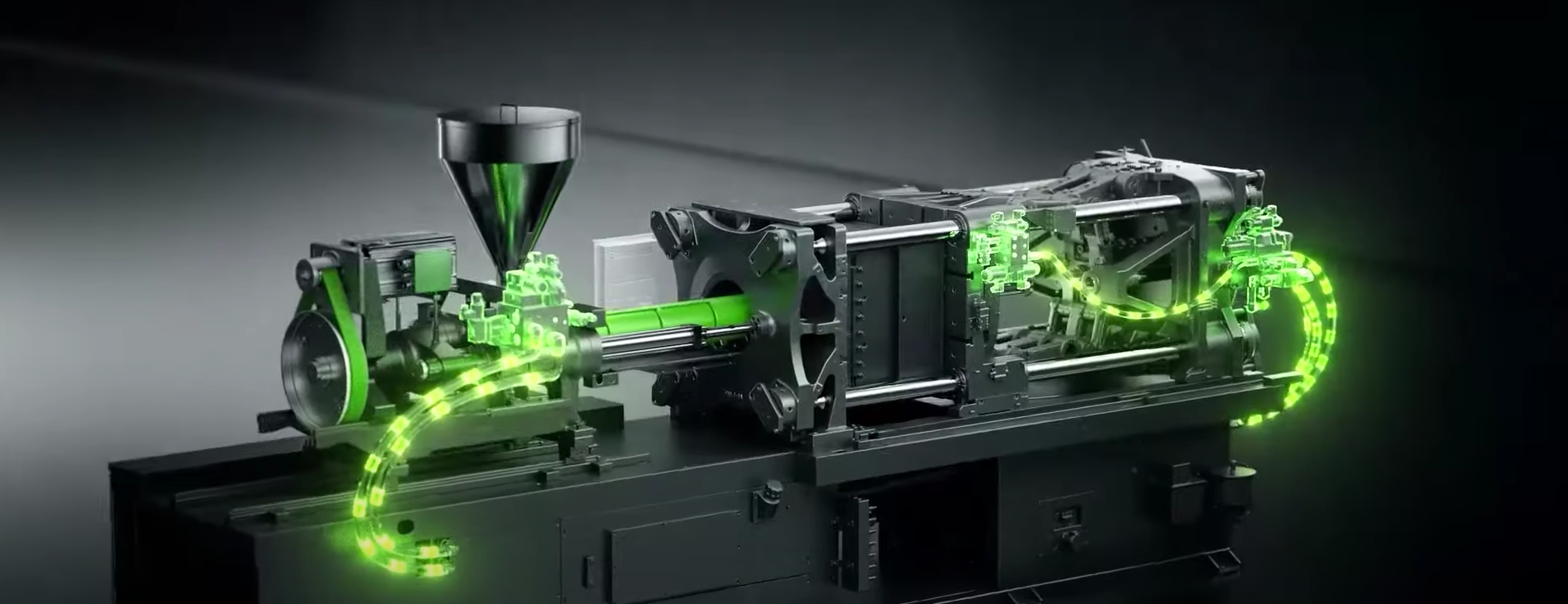

Rubber injection molding is a process that involves injecting heated rubber into a mold cavity, where it cools and solidifies into the desired shape. This technique allows for the production of complex and precise components that are essential in the medical field. The process begins with the preparation of the rubber material, which is heated and then injected under high pressure into a mold. Once in the mold, the rubber cools and takes the form of the cavity, resulting in a finished part that meets exact specifications.

1. Material Preparation - Raw rubber materials are selected based on specific performance requirements. Materials are weighed and mixed to achieve the desired compound, often including additives like accelerators, activators, and fillers.

2. Injection Unit - The rubber compound is fed into a heated barrel where it is heated and softened to a viscous state suitable for molding. Screw mechanisms or ram injectors force the material into the mold cavity under high pressure.

3. Mold Design and Clamping - The mold consists of two halves (core and cavity) designed to the shape and dimensions of the desired part. The mold is securely clamped shut to prevent leakage and maintain pressure during injection.

4. Injection and Curing - The heated rubber compound is injected into the mold cavity through a gate or sprue system. The mold is held closed under pressure until the rubber cures to the desired hardness and shape. Curing may be accelerated by heat or chemical agents depending on the type of rubber used.

5. Cooling and Ejection - Once cured, the mold is cooled to solidify the rubber part. The mold opens, and the finished part is ejected by ejector pins or automated systems. Excess material (flash) is trimmed or removed as necessary.

Advantages of Rubber Injection Molding for Medical Devices

Rubber injection molding offers numerous advantages for manufacturing medical devices, making it an ideal choice for the healthcare industry.

Precision and Consistency: Rubber injection molding provides high precision and consistency, which are crucial for medical devices that must meet stringent quality standards.

Efficiency: The process allows for the rapid production of large volumes of parts, significantly reducing lead times and increasing overall efficiency.

Complex Geometries: This molding technique can produce intricate and complex shapes that are often required for advanced medical devices.

Material Versatility: A wide range of rubber materials can be used, each offering unique properties such as flexibility, durability, and biocompatibility, essential for medical applications.

Cost-Effectiveness: Rubber injection molding is cost-effective for both high and low-volume production, making it suitable for various medical device manufacturing needs.

Applications of Rubber Injection Molding in Healthcare

Rubber injection molding is extensively utilized within the healthcare industry due to its capability to manufacture a diverse array of medical devices and components. This process is crucial for producing items such as silicone seals for medical instruments, elastomeric components for drug delivery systems, and intricate parts for surgical equipment.

Seals and Gaskets - Used in various medical devices to prevent leakage and ensure proper functioning.

Syringe Plungers - Precision-molded rubber parts ensure smooth operation and accurate dosing.

Medical Tubing - Flexible and durable rubber tubing is essential for many medical applications, such as IV lines and catheters.

Wearable Medical Devices - Custom rubber components are used in wearable devices that monitor patient health, providing comfort and durability.

Orthopedic Devices - Rubber injection molding produces components used in prosthetics and orthotics, offering high durability and comfort.

Quality Assurance and Compliance

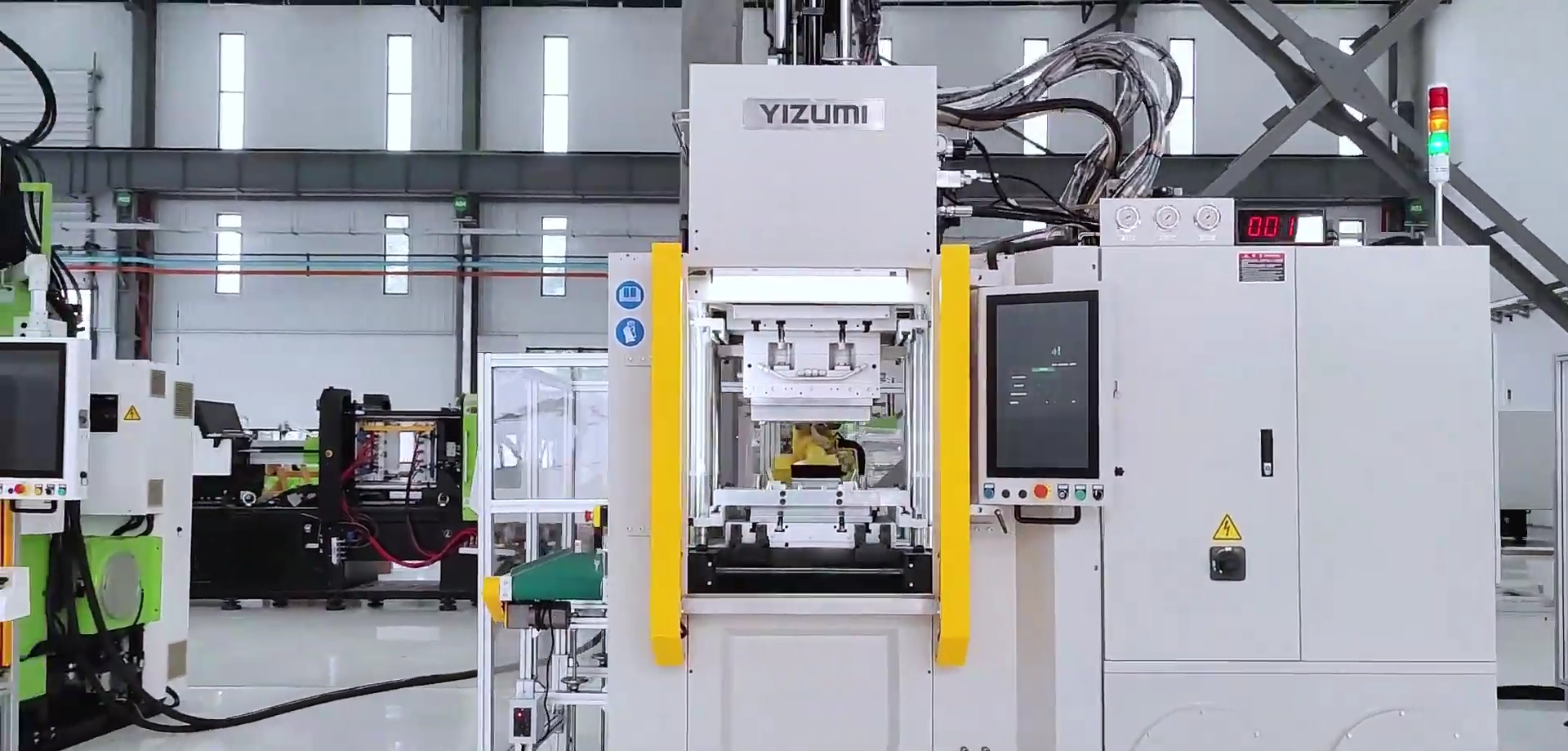

Ensuring the highest quality and compliance with regulatory standards is critical in medical device manufacturing. YIZUMI, a leader in rubber injection molding technology, offers state-of-the-art solutions designed to meet these stringent requirements.

YIZUMI's YL-Horizontal series represents a pinnacle in rubber injection molding technology, meticulously designed with input from a European technical team to meet rigorous standards of consistency, reliability, and speed for ensuring stable, high-quality automated production.

It offers unmatched flexibility, accommodating rubber, plastics, Liquid Silicone Rubber (LSR), and High Temperature Vulcanization (HTV) compounds, enabling efficient production across diverse demands. Energy efficiency is prioritized with a 3rd generation system that cuts energy consumption by up to 50%, supporting sustainable practices and reducing operational costs. CE safety standards ensure superior controllability, featuring precise screw speed control, proportional back pressure regulation, and advanced temperature management for consistent quality. Designed for agility, the series includes a retractable injection nozzle and easily disassembled injection piston, minimizing downtime and maximizing efficiency during compound changes. High-speed PLC systems facilitate seamless integration with Manufacturing Execution Systems (MES) and central control PCs, optimizing data exchange and production management. Automated ejecting devices and brush systems further enhance efficiency by streamlining O-ring production and mold cleaning, reducing manual labor and overall production costs.

YIZUMI's rubber injection molding machines excel in precision control, ensuring exact injection and consistent quality across all components. Designed to meet rigorous international standards for medical device manufacturing, these machines guarantee compliance with regulatory requirements. They combine high-speed production capabilities with top-tier quality, suitable for both large-scale production runs and smaller batches. User-friendly operation and maintenance are facilitated through intuitive design, minimizing downtime and boosting productivity. applications.

Conclusion

Rubber injection molding is at the forefront of innovation in medical device manufacturing, offering precise and reliable solutions for the complex needs of the healthcare industry. With its numerous advantages, wide range of applications, and potential for future advancements, this technology is driving efficiency, quality, and innovation in the production of essential medical components. YIZUMI, with its cutting-edge rubber injection molding machines, is leading the way in delivering superior solutions that meet the highest standards of the medical device industry.

For more information on YIZUMI’s rubber injection molding solutions and how they can benefit your medical device manufacturing processes, visit YIZUMI’s official website. Discover how YIZUMI is revolutionizing the world of rubber injection molding and setting new benchmarks for excellence in medical device production.