Electric injection molding revolutionizing manufacturing

Abstract:

Electric injection molding machines offer unparalleled precision and efficiency, greatly enhancing industry productivity. This article highlights how YIZUMI is at the forefront of technological change, providing superior solutions for a wide range of industries.

The manufacturing industry is constantly evolving, and one of the most significant advancements in recent years is the rise of electric injection molding. Offering unparalleled precision and efficiency, electric injection molding machines are transforming production processes across various sectors. This article delves into the benefits of electric injection molding, its applications, maintenance, and how YIZUMI is leading the charge with cutting-edge technology.

Why are electric injection molding machines preferred?

As the industry changes and evolves, electric injection molding machines have become the preferred choice for many manufacturers, the advantages are obvious.

Precision and Repeatability: Electric injection molding machines provide superior precision and repeatability compared to hydraulic machines. This is crucial for producing high-quality parts with tight tolerances.

Energy Efficiency: These machines are significantly more energy-efficient. They consume less power because they only use energy when needed, unlike hydraulic systems that run continuously.

Speed and Productivity: Electric machines offer faster cycle times, which enhances productivity. Their rapid response and high acceleration rates reduce production time.

Clean and Quiet Operation: Electric injection molding machines operate more quietly and without the risk of hydraulic fluid leaks, making them ideal for cleanroom environments.

Reduced Maintenance: With fewer moving parts and no hydraulic fluid, electric machines typically require less maintenance, leading to lower operational costs and increased uptime.

What Applications Benefit from Electric Injection Molding?

Electric injection molding machines are particularly beneficial for a wide range of applications that require precise and consistent manufacturing processes.

Medical Devices - Precision and cleanliness are paramount in the medical field. Electric injection molding ensures consistent quality for medical devices, surgical instruments, and diagnostic equipment.

Electronics - The production of electronic components requires precise molding to meet exact specifications. Electric machines provide the accuracy needed for these intricate parts.

Automotive - The automotive industry benefits from the high precision and repeatability of electric injection molding for producing components such as connectors, housings, and interior parts.

Consumer Goods -For products that require high-quality finishes and precise dimensions, electric injection molding is ideal. This includes items like plastic containers, toys, and household goods.

Aerospace - Components used in aerospace applications demand exacting standards. Electric injection molding meets these stringent requirements with high precision and consistency.

How to Maintain Electric Injection Molding Machines?

Maintaining electric injection molding machines is crucial for ensuring long-term performance and reliability. Here are some maintenance tips for you to care your facility!

1. Regular Inspection: Conduct regular inspections to identify and address any potential issues early. Check for wear and tear, loose connections, and proper lubrication.

2. Cleanliness: Keep the machine and its environment clean. Dust and debris can affect machine performance and lead to defects in molded parts.

3. Software Updates: Ensure that the machine’s software is up to date. Manufacturers often release updates that improve performance and address any known issues.

4. Calibration: Regularly calibrate the machine to maintain accuracy and precision. This is especially important for applications requiring tight tolerances.

5. Training: Provide ongoing training for operators to ensure they are familiar with the latest best practices and machine capabilities.

How does YIZUMI lead in electric injection molding technology?

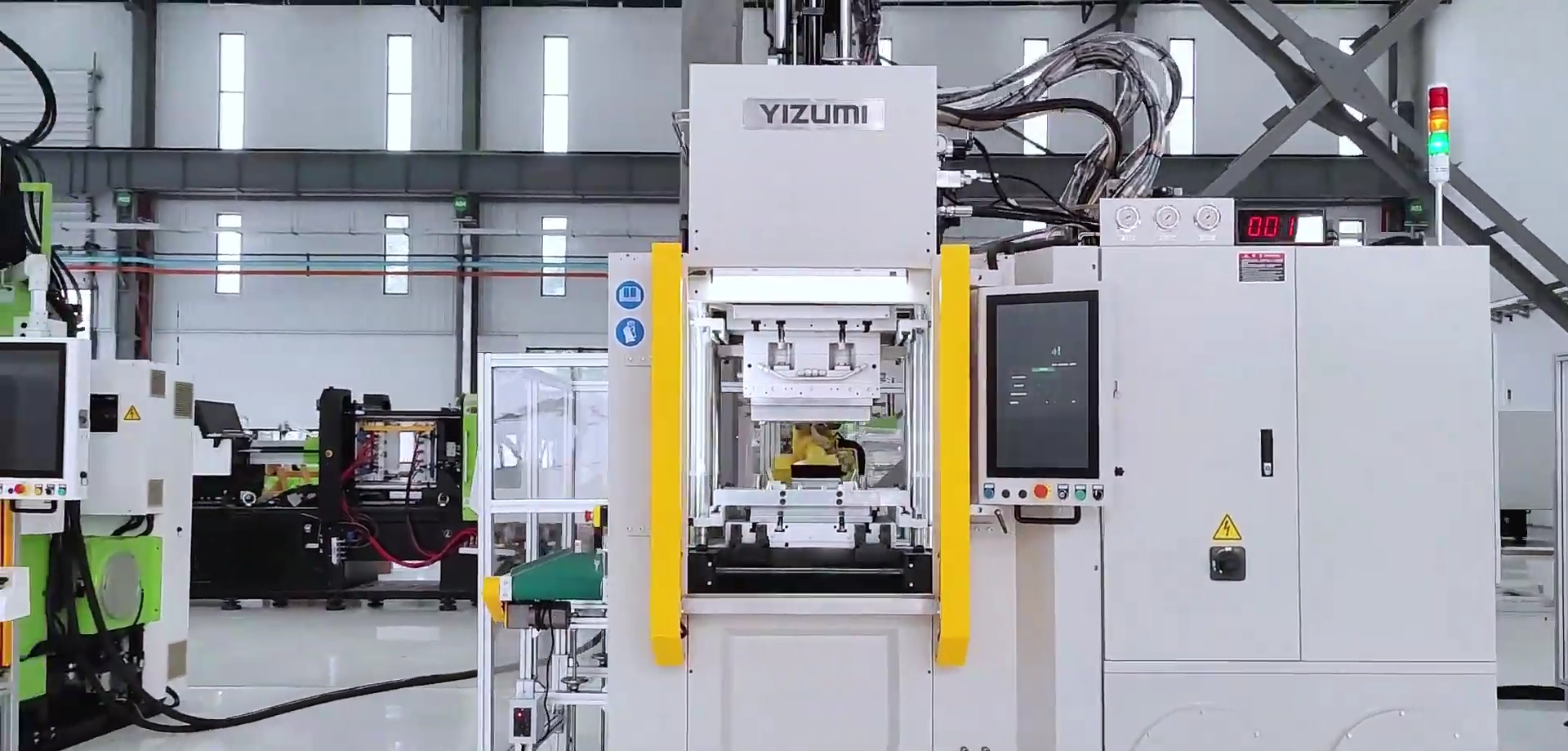

YIZUMI stands at the forefront of electric injection molding technology, offering innovative solutions that meet the diverse needs of modern manufacturers.

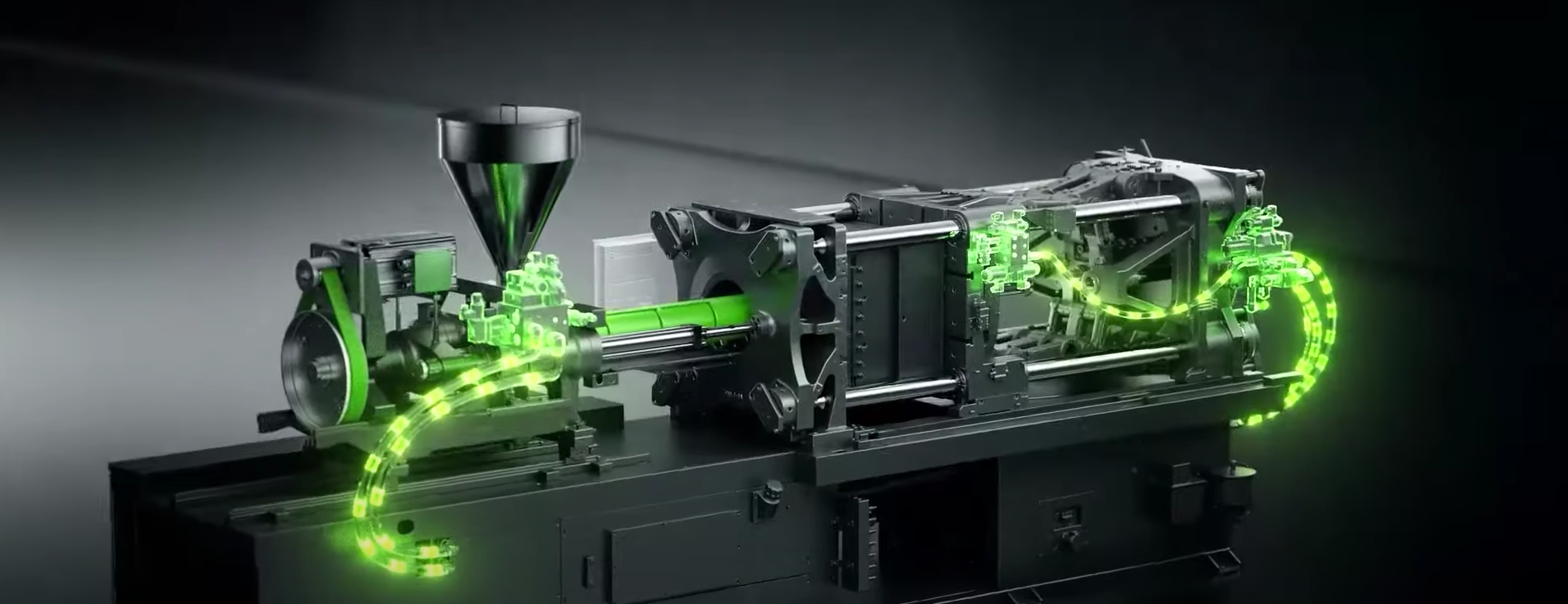

The YIZUMI FF Series Electric Injection Molding Machine stands out due to its advanced features and capabilities, surpassing traditional machine standards to enhance manufacturing efficiency and quality consistency. Designed to meet demanding core product needs, it offers clamping forces ranging from 900 to 13,800 kN.

-In the Clamping Unit, the FF Series utilizes a dual-cylinder parallel ejection design, ensuring uniform force application for mold release. This design achieves high precision with ejection position accuracy up to 0.2mm, crucial for maintaining product accuracy and repeatability. Additional functionalities include synchronized ejection modes, ejector retraction, and gate cutting inside the mold, enhancing operational versatility.

-The Injection Unit incorporates LGS (Linear Guide Support) technology for improved rigidity and reduced friction, enabling fast forward and backward movements without unnecessary resistance. A built-in hydraulic pump station and closed-loop injection pressure control technology further optimize performance, ensuring precise control over injection speed, position, and pressure.

-Unique servo direct control (SDC) technology enhances operational efficiency by independently controlling four servo motors for injection, plasticizing, clamping, and ejection. This setup allows for faster feedback, more responsive control, and enhanced accuracy in speed and pressure adjustments, meeting the stringent requirements of precision equipment.

-Managing these advanced capabilities is the European KEBA2000 Controller, which integrates standard Process Quality Control (PDP) and Statistical Process Control (SPC) features. It supports centralized real-time remote operation and control, facilitating seamless integration into networked manufacturing environments. Flexible I/O expansion modules enable further customization and programmability as per specific production needs.

In essence, the YIZUMI FF Series Electric Injection Molding Machine represents a technological leap forward, combining robust design with intelligent control features to deliver superior performance, reliability, and efficiency in modern injection molding operations. YIZUMI has been leading the way in electric injection molding technology, promoting the industry toward intelligence, high efficiency, and high precision with its profound accumulation of engineering technology, continuous technological innovation, and comprehensive customer support system.

The Future of Electric Injection Molding

Let's envision the future and trends of electric injection molding. Integration of Industry 4.0 technologies such as IoT and AI will enhance machine capabilities, enabling real-time monitoring, predictive maintenance, and advanced analytics to boost efficiency and productivity. Sustainable manufacturing will drive the development of more energy-efficient machines and promote the use of recyclable and biodegradable materials. Further advancements in technology will enhance precision and accuracy, expanding the applicability of electric injection molding to more demanding applications. Additionally, future machines will offer increased customization and flexibility, enabling manufacturers to swiftly adapt to evolving market needs and produce a broader range of products.

Conclusion

Electric injection molding is revolutionizing the manufacturing industry by offering unmatched precision, efficiency, and versatility. YIZUMI leads the way with its advanced technology and commitment to excellence, providing manufacturers with top-tier solutions for a wide range of applications. As the industry continues to evolve, YIZUMI’s innovative approach ensures that they remain at the forefront of electric injection molding technology, helping manufacturers achieve greater productivity and sustainability.

For more information about YIZUMI’s electric injection molding machines and how they can benefit your operations, visit YIZUMI’s official website. Embrace the future of manufacturing with YIZUMI’s cutting-edge solutions and discover the difference that industry-leading technology can make.

How to Maintain Electric Injection Molding Machines?

Maintaining electric injection molding machines is crucial for ensuring long-term performance and reliability. Here are some maintenance tips for you to care your facility!

1. Regular Inspection: Conduct regular inspections to identify and address any potential issues early. Check for wear and tear, loose connections, and proper lubrication.

2. Cleanliness: Keep the machine and its environment clean. Dust and debris can affect machine performance and lead to defects in molded parts.

3. Software Updates: Ensure that the machine’s software is up to date. Manufacturers often release updates that improve performance and address any known issues.

4. Calibration: Regularly calibrate the machine to maintain accuracy and precision. This is especially important for applications requiring tight tolerances.

5. Training: Provide ongoing training for operators to ensure they are familiar with the latest best practices and machine capabilities.

How does YIZUMI lead in electric injection molding technology?

YIZUMI stands at the forefront of electric injection molding technology, offering innovative solutions that meet the diverse needs of modern manufacturers.

The YIZUMI FF Series Electric Injection Molding Machine stands out due to its advanced features and capabilities, surpassing traditional machine standards to enhance manufacturing efficiency and quality consistency. Designed to meet demanding core product needs, it offers clamping forces ranging from 900 to 13,800 kN.

(https://www.yizumi.com/en/ims/ff-series-electric-injection-molding-machine)

-In the Clamping Unit, the FF Series utilizes a dual-cylinder parallel ejection design, ensuring uniform force application for mold release. This design achieves high precision with ejection position accuracy up to 0.2mm, crucial for maintaining product accuracy and repeatability. Additional functionalities include synchronized ejection modes, ejector retraction, and gate cutting inside the mold, enhancing operational versatility.

-The Injection Unit incorporates LGS (Linear Guide Support) technology for improved rigidity and reduced friction, enabling fast forward and backward movements without unnecessary resistance. A built-in hydraulic pump station and closed-loop injection pressure control technology further optimize performance, ensuring precise control over injection speed, position, and pressure.

-Unique servo direct control (SDC) technology enhances operational efficiency by independently controlling four servo motors for injection, plasticizing, clamping, and ejection. This setup allows for faster feedback, more responsive control, and enhanced accuracy in speed and pressure adjustments, meeting the stringent requirements of precision equipment.

-Managing these advanced capabilities is the European KEBA2000 Controller, which integrates standard Process Quality Control (PDP) and Statistical Process Control (SPC) features. It supports centralized real-time remote operation and control, facilitating seamless integration into networked manufacturing environments. Flexible I/O expansion modules enable further customization and programmability as per specific production needs.

In essence, the YIZUMI FF Series Electric Injection Molding Machine represents a technological leap forward, combining robust design with intelligent control features to deliver superior performance, reliability, and efficiency in modern injection molding operations. YIZUMI has been leading the way in electric injection molding technology, promoting the industry toward intelligence, high efficiency, and high precision with its profound accumulation of engineering technology, continuous technological innovation, and comprehensive customer support system.

The Future of Electric Injection Molding

Let's envision the future and trends of electric injection molding. Integration of Industry 4.0 technologies such as IoT and AI will enhance machine capabilities, enabling real-time monitoring, predictive maintenance, and advanced analytics to boost efficiency and productivity. Sustainable manufacturing will drive the development of more energy-efficient machines and promote the use of recyclable and biodegradable materials. Further advancements in technology will enhance precision and accuracy, expanding the applicability of electric injection molding to more demanding applications. Additionally, future machines will offer increased customization and flexibility, enabling manufacturers to swiftly adapt to evolving market needs and produce a broader range of products.

Conclusion

Electric injection molding is revolutionizing the manufacturing industry by offering unmatched precision, efficiency, and versatility. YIZUMI leads the way with its advanced technology and commitment to excellence, providing manufacturers with top-tier solutions for a wide range of applications. As the industry continues to evolve, YIZUMI’s innovative approach ensures that they remain at the forefront of electric injection molding technology, helping manufacturers achieve greater productivity and sustainability.

For more information about YIZUMI’s electric injection molding machines and how they can benefit your operations, visit YIZUMI’s official website. Embrace the future of manufacturing with YIZUMI’s cutting-edge solutions and discover the difference that industry-leading technology can make.

(https://www.yizumi.com/en/)