Comprehensive Maintenance Routines for Plastic Injection Molding Machines: Ensuring On-Time Production

Abstract:

Learn essential preventive maintenance routines for plastic injection molding machines. Discover how YIZUMI's service support and products help minimize downtime and maximize efficiency.

Introduction:

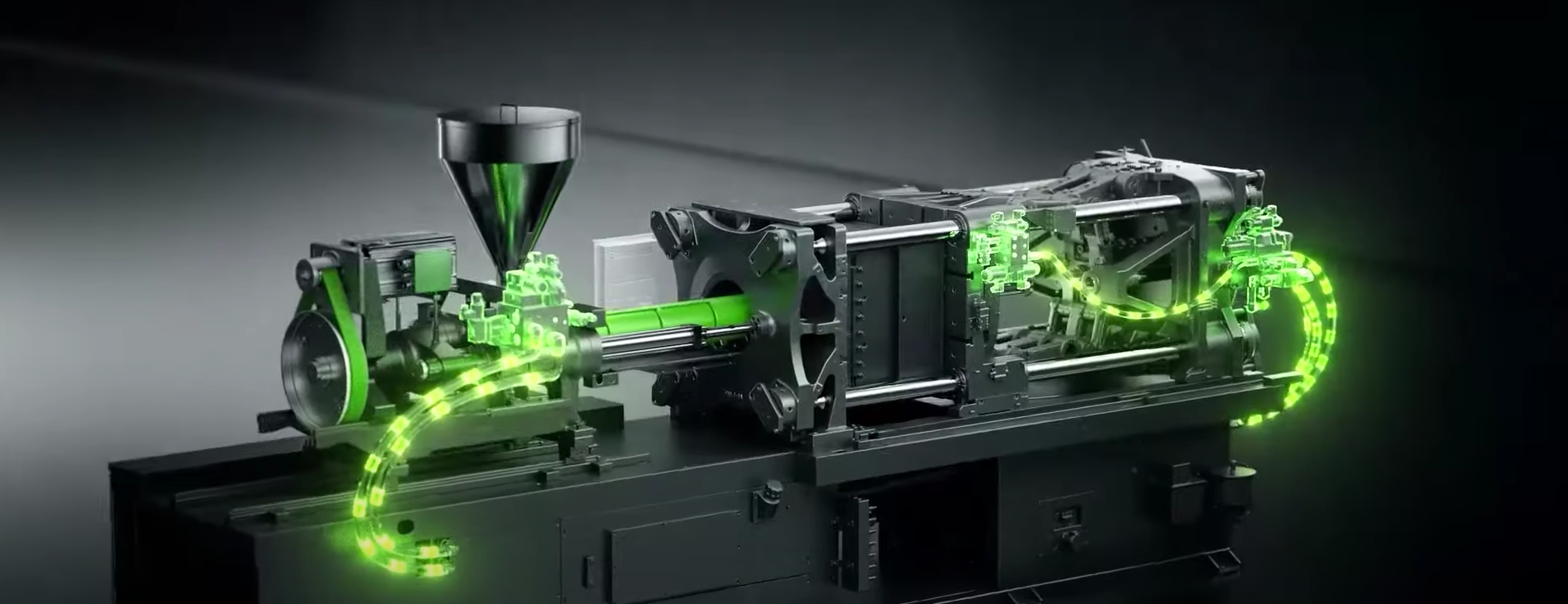

In the competitive landscape of plastic injection molding, ensuring machine reliability and consistent performance is vital. Implementing a robust preventive maintenance strategy is key to avoiding unexpected machine stoppages and ensuring continuous production. This guide explores essential maintenance routines and the role of YIZUMI's advanced support and products in maintaining production efficiency.

Section 1: Common Causes of Unwanted Machine Stoppage:

Unwanted stoppages in plastic injection molding machines often result from mechanical wear, electrical failures, overheating, and improper settings. These issues can lead to significant downtime and losses. Regular preventive maintenance is crucial to address these problems before they escalate.

Section 2: Daily Walk-Around Inspections for Operators:

Daily walk-around inspections are an essential part of a preventive maintenance routine. Operators should perform visual checks for wear and damage, monitor temperature settings, ensure proper lubrication, and verify machine settings to maintain optimal operation.

Section 3: Maintenance Team Inspections:

In addition to daily checks, the maintenance team should conduct more detailed inspections, including electrical system checks, assessing mechanical integrity, inspecting the hydraulic system, and ensuring proper calibration and alignment. These comprehensive inspections help maintain the injection molding machine in top condition.

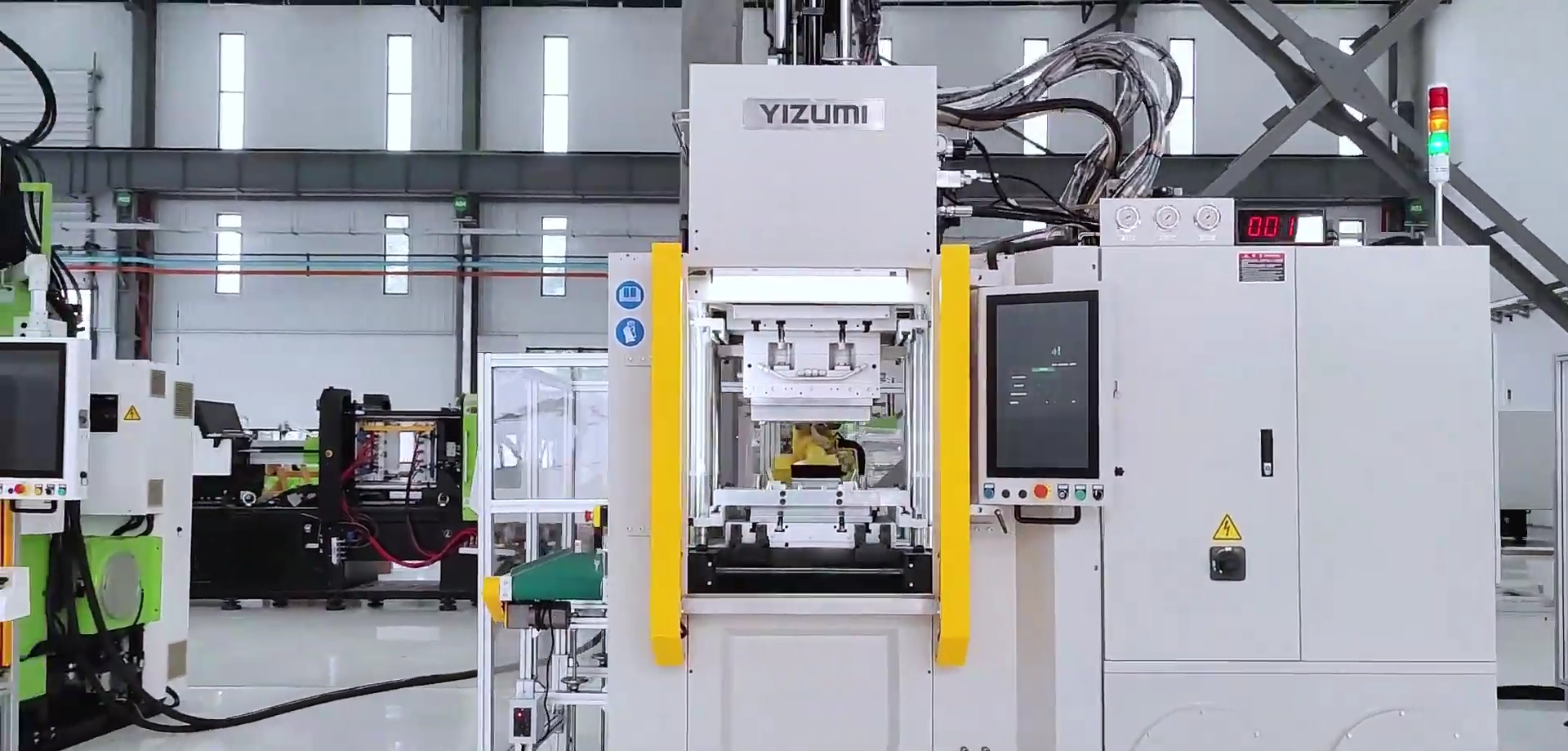

Section 4: YIZUMI's Service Support & Products for Preventive Maintenance:

YIZUMI provides tailored preventive maintenance solutions to enhance machine reliability. With tools like remote monitoring and diagnostics, scheduled maintenance programs, and access to genuine parts and upgrades, YIZUMI helps manufacturers maintain efficient production and minimize downtime.

Section 5: Overlooked Preventive Maintenance Methods:

Often overlooked, regular training for operators and maintenance teams is vital for effective preventive maintenance. Maintaining a clean and organized workspace also plays a crucial role in preventing contaminants from affecting machine performance.

Conclusion:

Prioritizing preventive maintenance routines for plastic injection molding machines is essential for minimizing downtime and ensuring consistent production quality. With YIZUMI's support, manufacturers can optimize their maintenance strategies, reduce costs, and achieve greater profitability in their operations.