Official announcement: YIZUMI Won the Bid for the Car Body Integrated Die-Casting Project of Changan Auto

Abstract:

On August 26th, YIZUMI was informed that it has won the bid for the 4 sets ultra-large die-casting machines of the BIW integrated die-casting project of Chongqing Chassis System Company, a branch of China Changan Automobile Group.

On August 26th, YIZUMI was informed that it has won the bid for the 4 sets ultra-large die-casting machines of the BIW integrated die-casting project of Chongqing Chassis System Company, a branch of China Changan Automobile Group. Since the strategic cooperation with FAW Foundry in the field of ultra-large integrated die casting, it is the second close cooperation between YIZUMI and "National Team".

*Changan Auto and FAW are two of the China’s four major state-owned auto manufacturers.

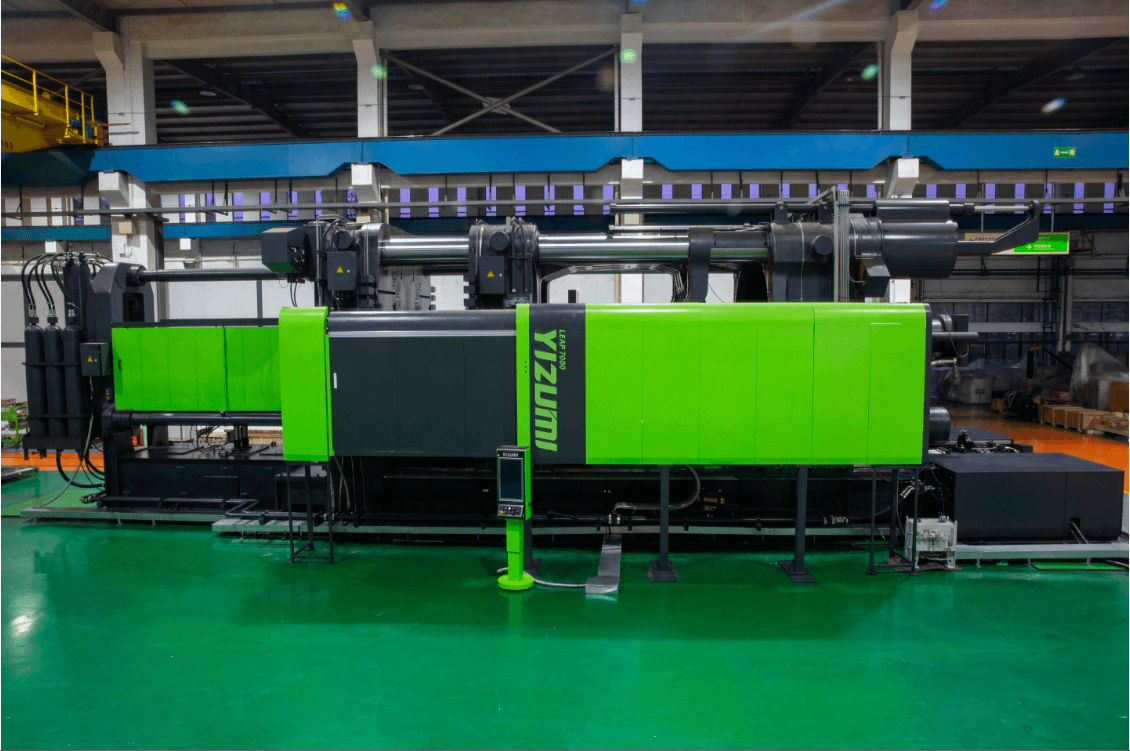

The YIZUMI LEAP series ultra-large die casting machine

Benchmarking with the world-class performance to make die casting easier

The ultra-large die-casting machine that has won the bid is the result of YIZUMI's latest development efforts based on market demand and trends in the die-casting industry. The YIZUMI LEAP series ultra-large die casting machines were developed providing state-of-the-art technology to its customers including highest casting precision, cutting-edge injection capacity along with top of the line process repeatability as well as low energy consumption. The YIZUMI LEAP is uniquely suited to meet the strict production and quality requirements of ultra-large die casting parts for new energy vehicles. It fully benchmarked against the performance and functions of world-class die casting machines.

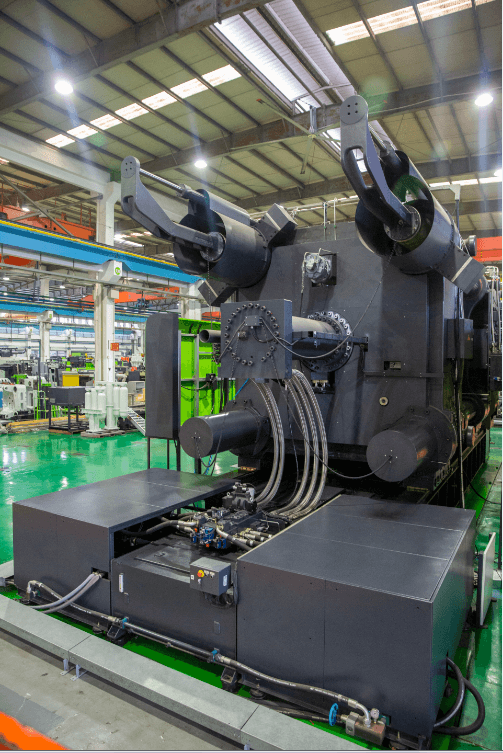

The self-developed Yi-Cast injection system represents a breakthrough for YIZUMI die casting by achieving world-class injection performance on precision and process repeatability. Yi-Cast’s real-time-closed-loop injection technology ensures highest quality casting performance from shot to shot over the entire production volume.

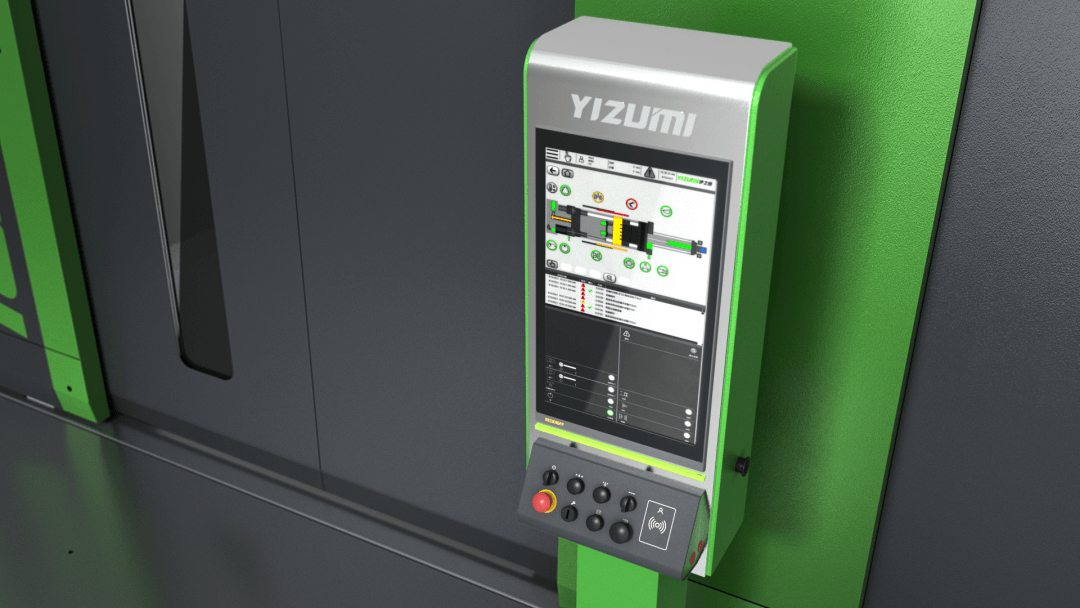

The highly intuitive ORCA control system offers advanced control technology and its smart algorithms ensure first-rate casting capabilities. Monitoring up to 100 relevant process parameters of the die casting cell allows for easy integration of the system into fully digitized manufacturing execution systems (MES) for efficient product traceability as well as quality management.

With its innovative and energy saving hydraulic drive group combined with the new, durable and efficient YIZUMI die closing system, the LEAP machine provides an equipment platform providing its user to achieve highest Overall-Equipment-Effectiveness (OEE).

Yi-Cast Injection System

ORCA Control System

Upgraded locking Unit

The state-of-the-art LEAP series die casting machine technology is the result of YIZUMI's new development strategy and the hard work from its international R&D team, which consists of experts with decades of experience in the die-casting industry. The team integrates advanced technologies from China and Europe, conducts independent research and development in an all-round way with completely self-owned intellectual property rights. The LEAP technology meets highest requirements on performance, function and production process of the fast-growing die-casting industry. It also well fulfills customer requirements with systematic intelligent solutions which makes the LEAP system suitable for various complex die-casting processes while it offers easy-to-understand, intuitive programming.

Significant progress of YIZUMI in the field of ultra-large integrated die casting

The integrated die-casting technology mainly refers to the integrated manufacturing of body structural parts. Many independent and separated parts in traditional designs are integrated into one large casting and cast on ultra-large die casting machines. Comparing with the traditional stamping and welding BIW manufacturing process, the new technology can greatly reduce costs and the number of parts, thereby improving production efficiency. The technology of integrating functions may also be applied to the manufacturing of NEV housings of the electric motors, control and drive systems, as well as large battery housings, which are all component segments expected to grow strongly with the current shift towards electro mobility.

The winning of this important bid is a significant progress of YIZUMI in the field of ultra-large structural die casting. It is not only the recognition for YIZUMI's manufacturing and delivery capabilities, but also a strong sign of YIZUMI’s commitment to provide global customers with excellent, highly productive solutions and services.

For more detailed information, please feel free to contact us.

Email:dcsolutions@yizumi.com