New Integrated Design- YIZUMI Launched the Second Generation of H Series Die Casting Machine (1800-45000 kN)

Abstract:

New Integrated Design- YIZUMI Launched the Second Generation of H Series Die Casting Machine (1800-45000 kN)

In 2016, YIZUMI launched the H series die casting machine, whose quality is comparable to the quality standards of European and American equipment, and its stability and high repeatability have won recognition from many customers around the world. YIZUMI heavy-duty die casting solutions with machines sizes of 3500T, 4000T, 4500T helped some well-known Chinese companies such as CNHTC, LIJIA, RUNXINGTAI, WUXI LANGSHION, Wenzhou RUIMING, Dongguan JIANSHENG realize mass production of large castings, which include gearbox housings for trucks, 5G base stations, battery housings for new energy vehicle as well as structural castings incl. shock towers, instrument panels, etc. At the same time, many H series die-casting machines have been exported to other countries and regions, such as Europe, Asia, America, receiving positive comments from overseas customers.

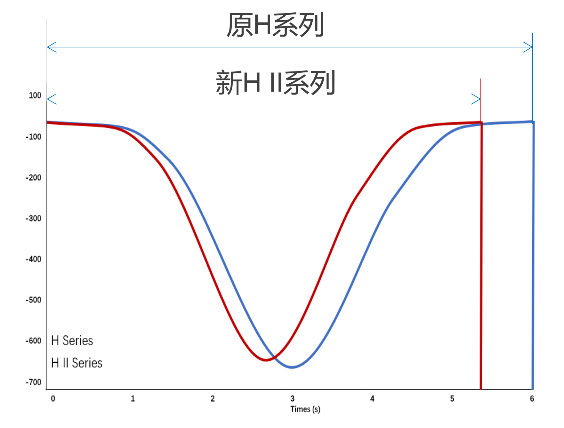

Based on years of experience in the use of H series die-casting machines in customer sites, the YIZUMI Chinese technical team, together with a European technical expert team, launched the second generation of H series die-casting machines (1800-45000 KN), whose injection performance, mold opening and clamping performance as well as overall stability have been significantly upgraded. The brand-new H series provides customers with more precise injection control, higher repeatability, and manufacturing capabilities to meet international quality requirements providing great benefits to the market.

1. Upgraded Injection Unit, Top Injection Capability

① A new integrated injection hydraulic adds injection performance and casting process stability while reducing components and increasing machine availability.

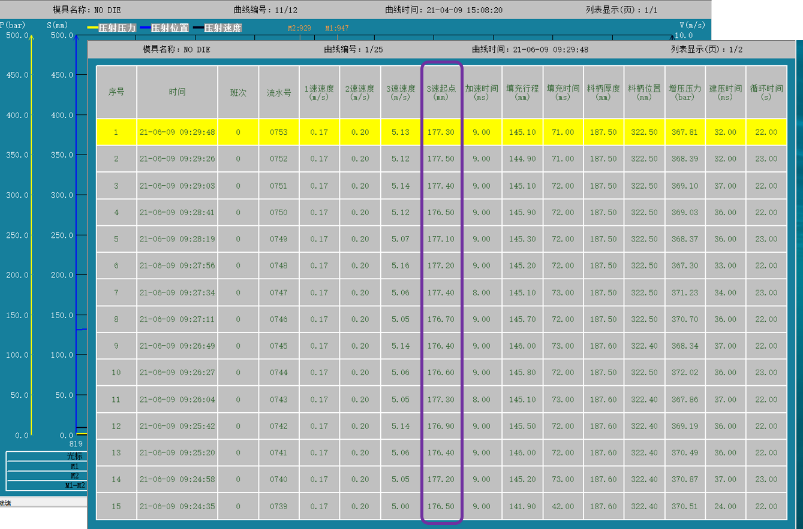

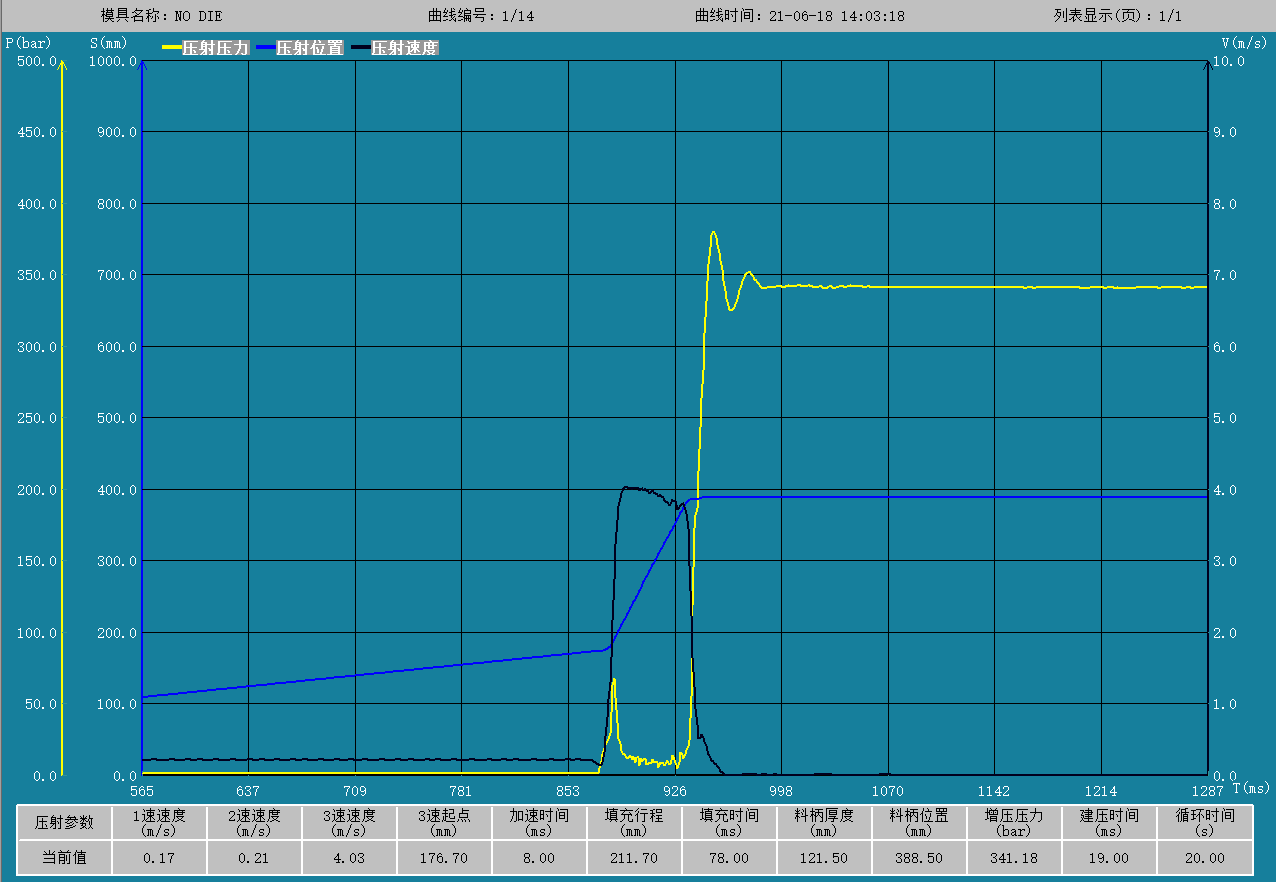

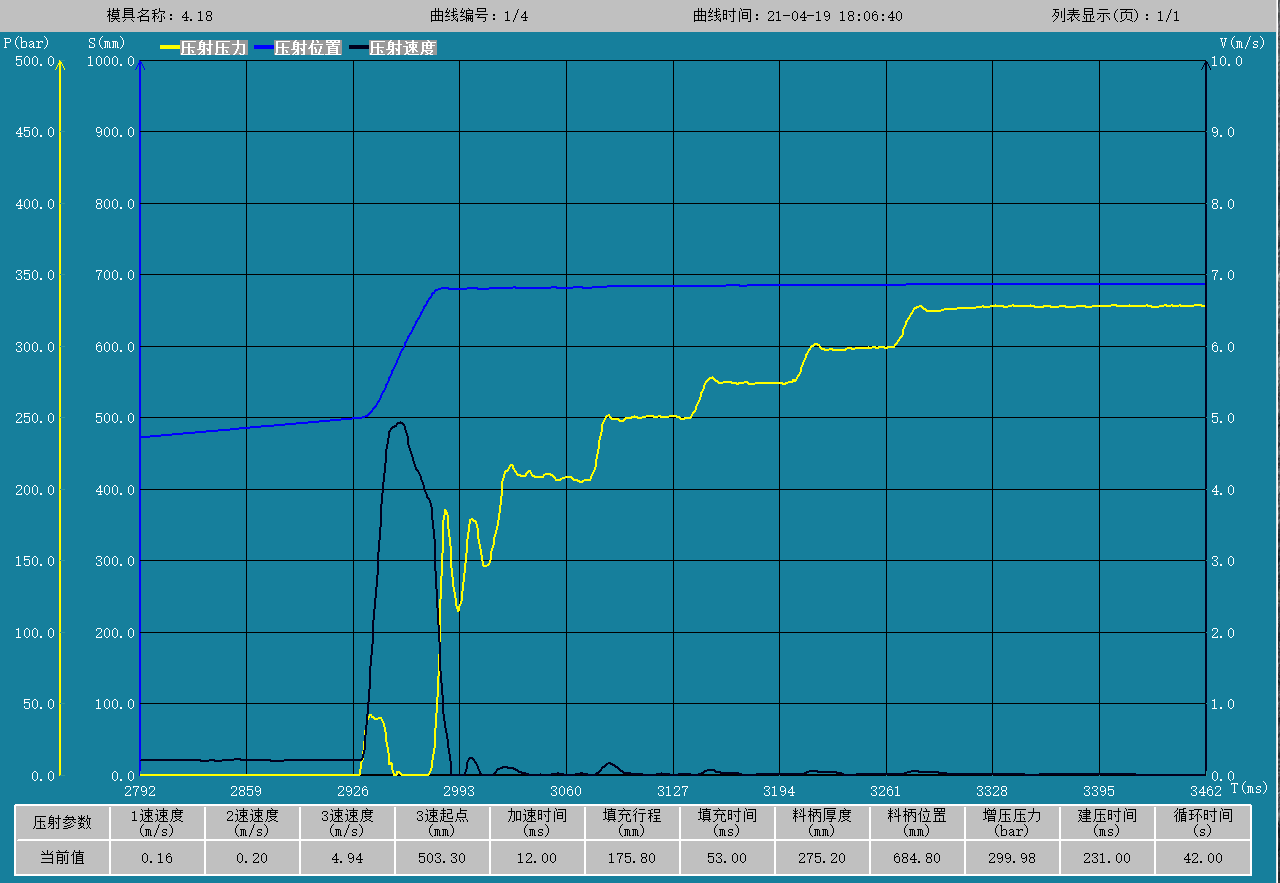

② Highly precise & repeatable switch-over to fast filling phase further increases casting process consistency for our customers. These improvements are based on a successful international engineering cooperation. Precisely triggering the fast-filling phase is critical for many die casting applications. The H II provides a high standard of precision to switch-over to the cavity filling phase and significantly reduces V1 starting vibration. A repeatability of max +/-3mm satisfies the highest requirements.

③ With its optimized hydraulic system, the H II system offers high injection acceleration (small-sized machine ≥50G, large-sized machine≥40G). In combination with its high-capacity P/Q performance, the H II die casting machine is built to provide high casting quality with even the most difficult of parts.

④ A 30% improved pressure build-up time offers an intensification performance satisfying even the most challenging of applications.

⑤ Increased casting process transparency saves time and eases programming. Based on technology data entry the YIZUMI H II control system calculates critical casting process data to support process engineers(specific screen Type is needed). The PQ2 diagram showing the actual operating point is displayed on the HMI screen to support the process engineer with great transparency(Specific Screen Type is needed).

⑥ Optional real-time closed-loop control systems ensure quality consistency over long periods of time. Pressure, speed real-time detection and automatic correction of process parameters enable a high degree of consistency in the customer's production process. Available as an option is our closed-loop system with automatic self-learning function and motor driven cartridge valve adjustment, allowing customers to set pressure and speed values conveniently on the HMI.

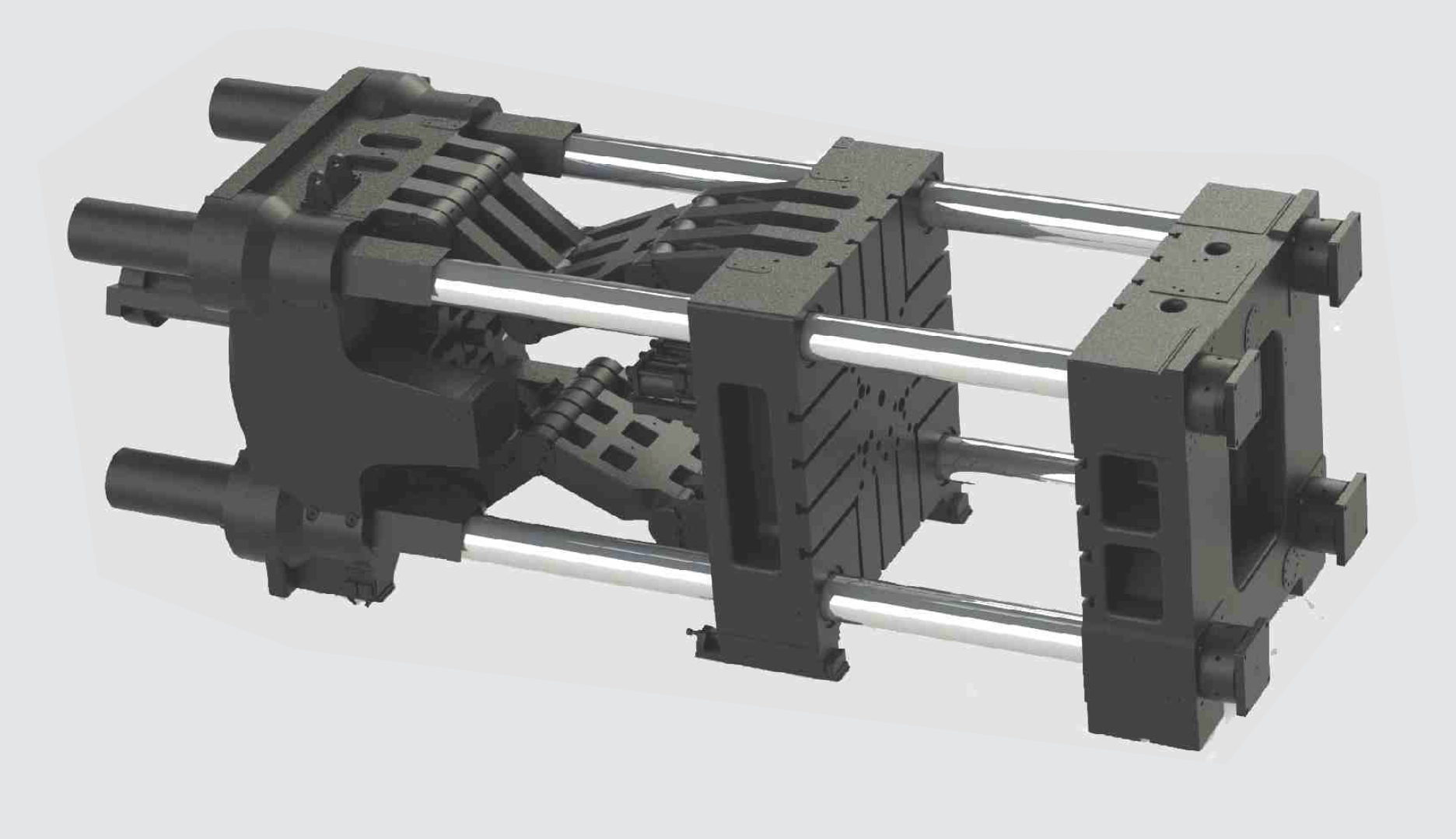

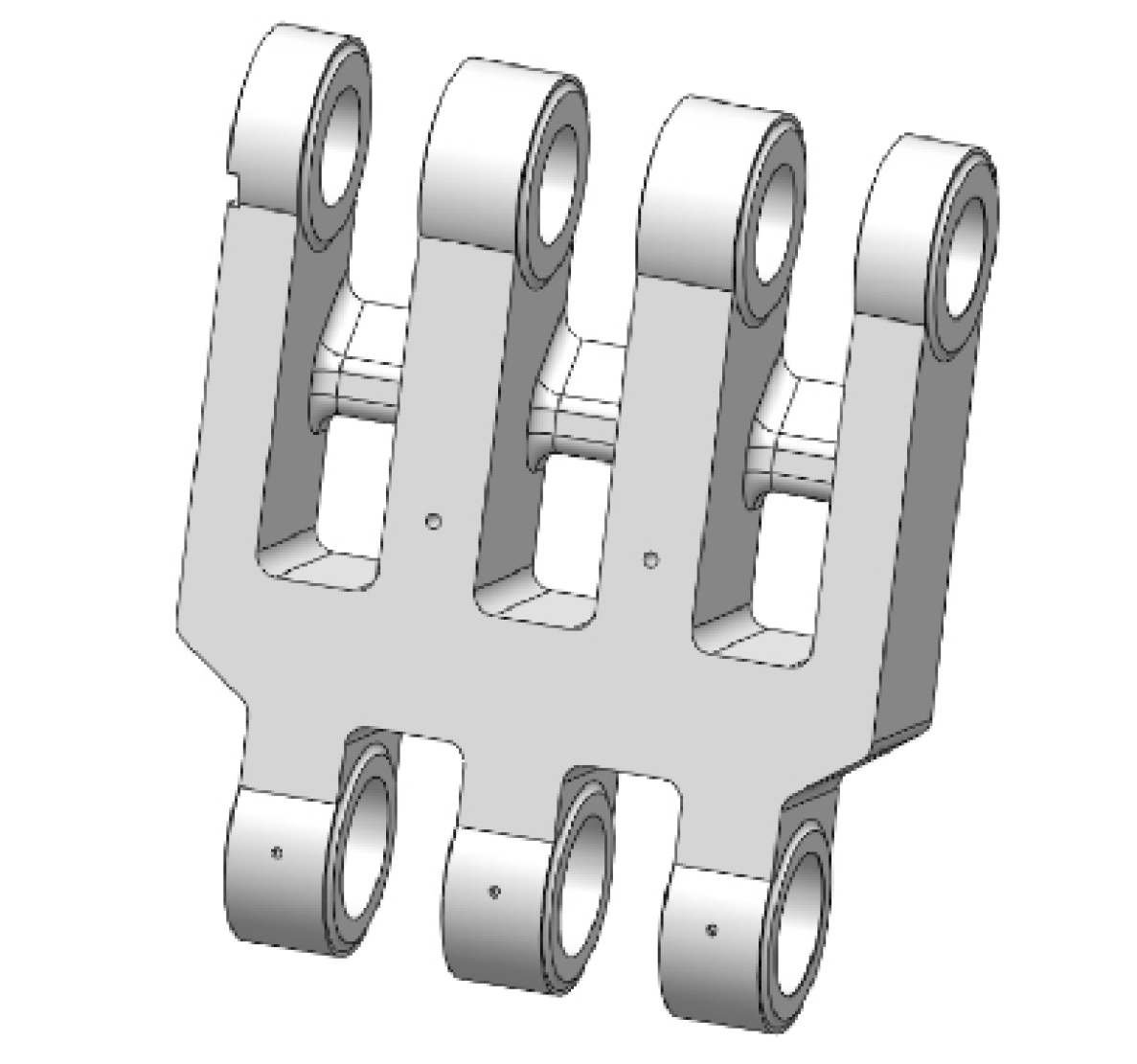

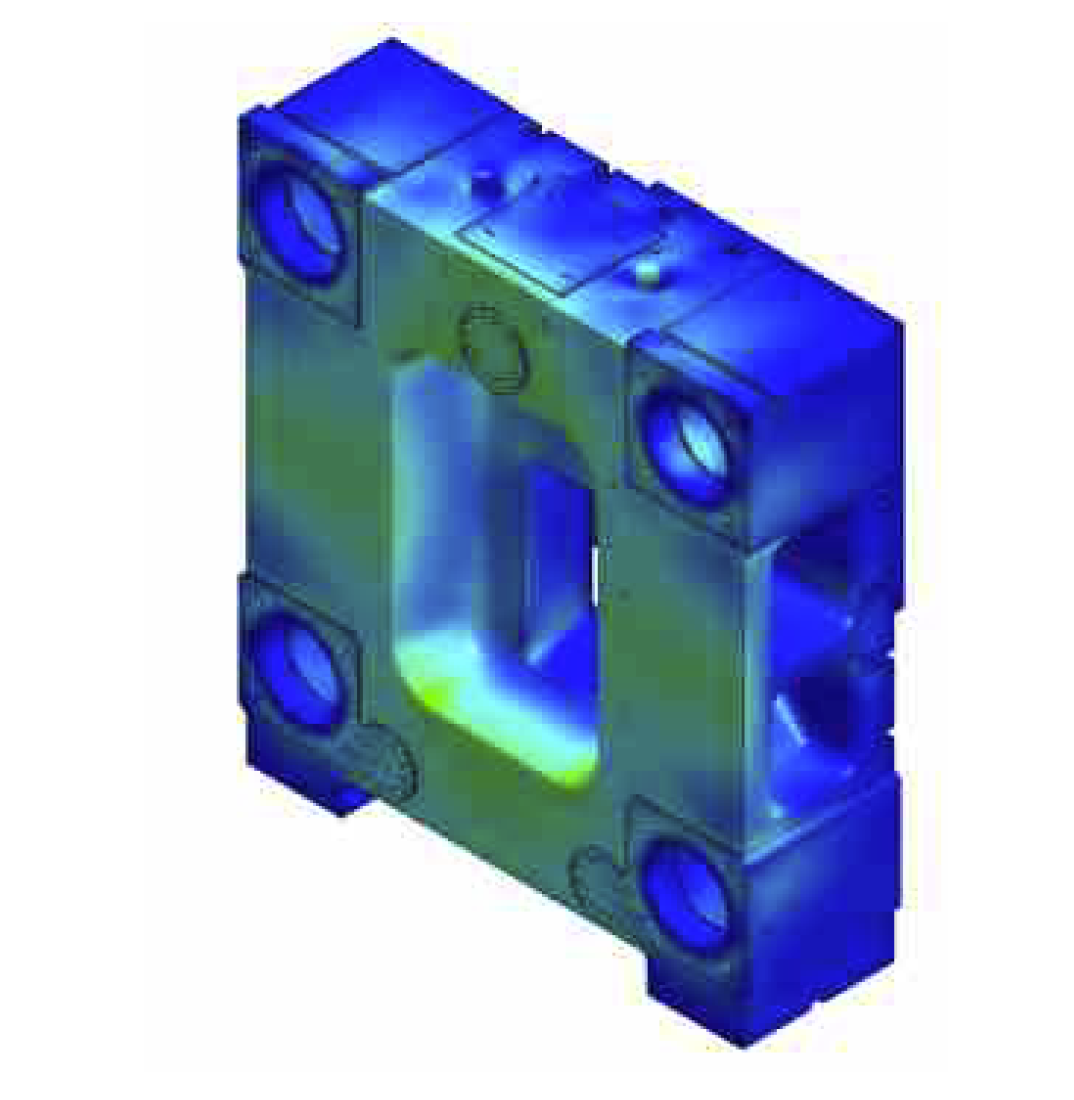

2.The HⅡ internalizes advanced design concepts and offers re-Engineered, high-strength clamping units to ensure faster opening & closing speeds, higher platen rigidity, and longer toggle service life.

① Applying finite element analysis allowed platen weight reductions making for faster opening and closing movements.

② A new design based on FEM analysis offers an even distribution of force while minimizing platen bending. Optimized clamping unit shortens cycle times, significantly increases platen rigidity and improves customer's overall production output.

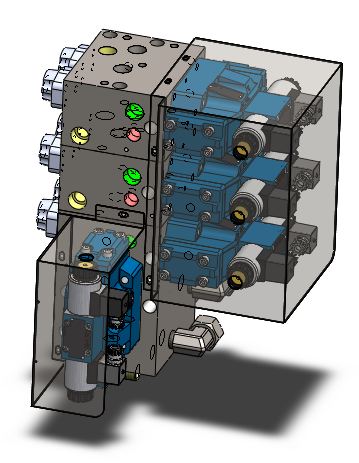

3.High Performance Hydraulic Drive System

① A well-balanced hydraulic drive system supports faster cycle times at lowest energy consumption. High quality, energy efficient and with higher capacity, this hydraulic drive allows fastest hydraulic movements of die, cores and accu charging to support our customer`s high OEE expectations.

② Highest quality standards and fast delivery times are made possible by the YIZUMI modular machine design which includes concurrent manufacturing and testing of individual machine modules. A large variety of selectable functional options further benefit our customers.

4.International Standard Electrical Control System

① Our high level design complies with worldwide safety standards. Short-Circuit breakers effectively protect circuit boards and electronic components.Automatic pre-warning alarms of fluid levels (hydraulic oil / lubrication) and temperatures (hydraulic oil /cabinet temperature) ensure a stable and highly productive operation of YIZUMI equipment.

② The integrated operating panel is easy to use and saves time for the operator aswell as the casting process engineers. Finding functions, monitoring production, and setting parameters are made easy by a structured HMI menu on alarge touch screen.

③ The new and optimized HMI offers intuitive and easy-to-understand maintenance functions, maintenance tips and comprehensive alarm information as well as operation guidance. Operational efficiency is further improved by user-friendly functions such as production start with reduced speed and pressure, plunger friction detection and precise, vibration free slow speed during the pre-filling phase.

④ The HII control system features standardized interfaces offering great flexibilityin the choice of peripherals. Cell integration made easy.

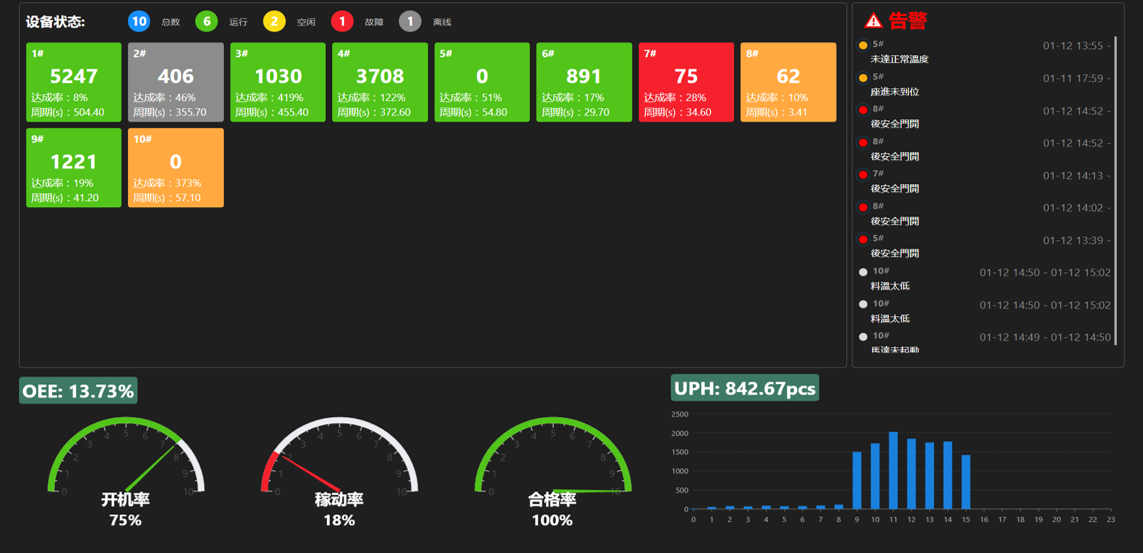

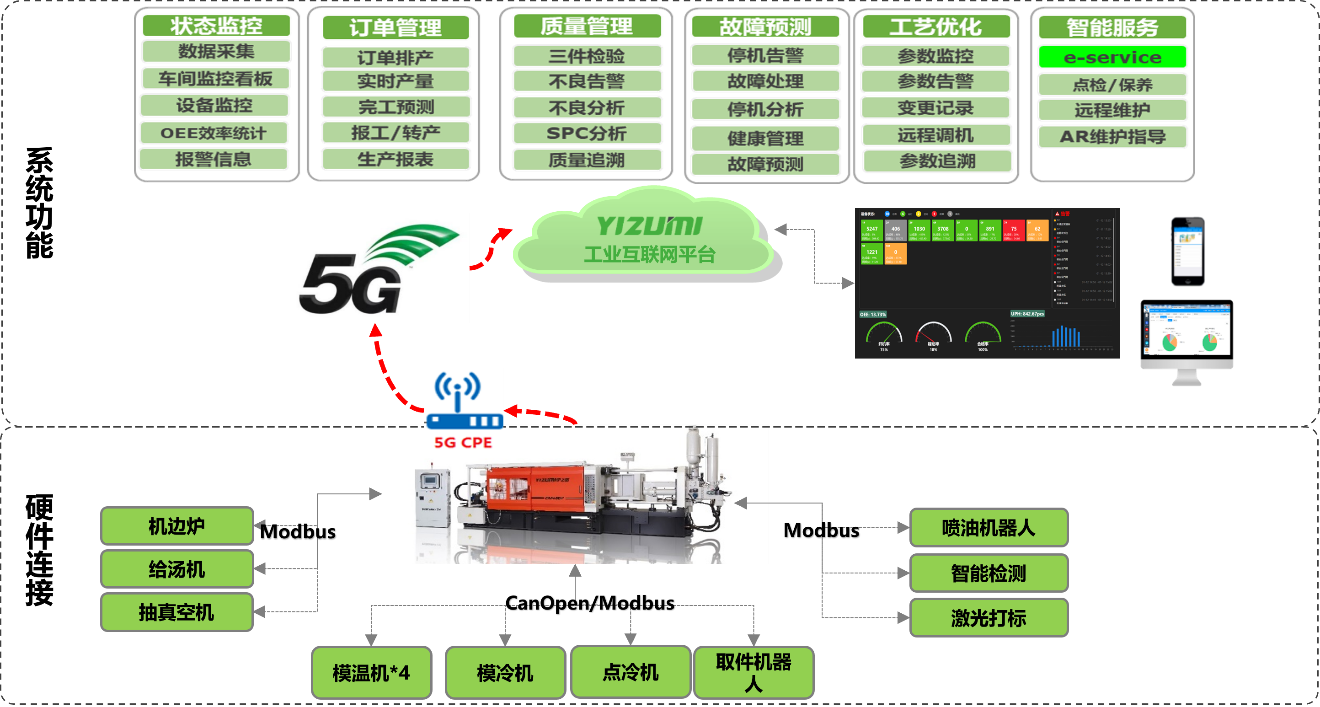

5.Yi-MES System(Option)

Specially designed for the die casting industry, the Yi-MES system is a great choice for SMEs. Its multiple functional modules ensure efficient management, help facilitate production plan and achieve digitized monitoring and quality management. Yi-MES system provides professional digital factory solutions forthe whole die-casting process.