The Road to LEAP—A Story of YIZUMI LEAP Series Die Casting Machine

Abstract:

The Road to LEAP—A Story of YIZUMI LEAP Series Die Casting Machine

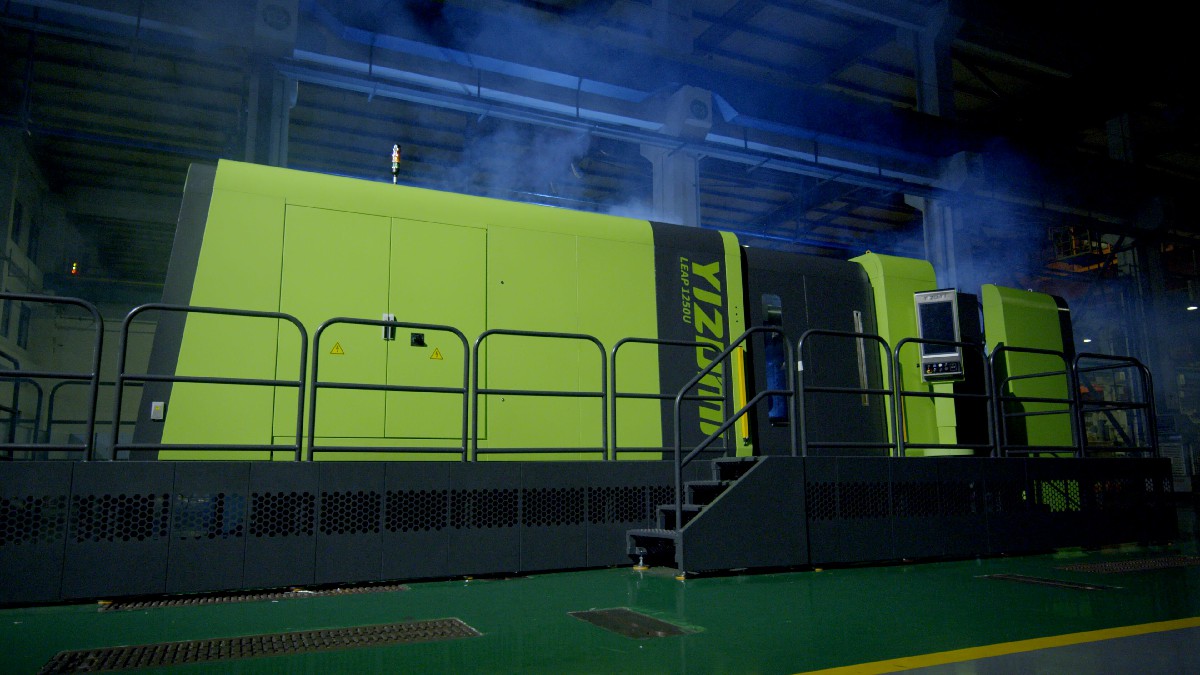

In recent years, under the general trend of energy conservationand emission reduction, the global demand for new energy vehicles has usheredin rapid growth. The die-casting industry is facing a new round oftransformation and upgrading with new energy vehicles putting forward higherrequirements for die-casting technology and complex thin-walled die-castingparts. After extensive market research and benchmarking advanced international technology, YIZUMI addresses future challenges with its new generation LEAP series of die casting machines. LEAP offers highest precision and repeatability coupled with a modern control system offering intuitive and easy operation. This technology platform lays the foundation for smart cell integration ensuring highest equipment availability. To further support our customers to achieve competitive OEE, YIZUMI is building up top class capabilities in the fields of die design and casting process optimization.

Breaking the boundaries

to provide customers with the best return on investment

YIZUMI’s new generation LEAP series die-casting machine offers customers a higher overall equipment effectiveness (OEE) based on the independently developed Yi-Cast real time closed loop injection to improve overall casting performance with its world class precision and process consistency.

In addition, complemented by a highly innovative and energy-saving hydraulic drive-group as well as a state-of-the-art HMI featuring customer focused intuitive programming, the LEAP series allows intelligent exchange of information regarding quality, operational performance, and parameter settings, making the management of YIZUMI’s solutions easy, efficient, and transparent.

“The LEAP series die-casting machines deliver the best return on investment for our customers.” As Stefan Fritsche, YIZUMI CSO for Die Casting &Metal Forming, said, “To bring real and competitive value to our customers, YIZUMI decided that a holistic approach would be the key to this revolutionary leap.”

At the beginning of product development, YIZUMI actively applied its IPD (Integrated Product Development) method, with its market-orientation and focus on customer needs & requirements. We learned to understand the pain-points of customers’ employees in their diverse roles in actual production and use of die casting equipment. Through several years of in-depth observation and research, we obtained first-hand feedback, which helped LEAP products to achieve a leap in key performance.

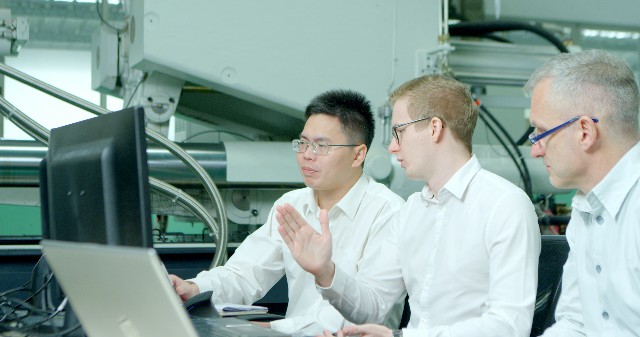

"Deep Connection" is the driving force behind YIZUMI's technological leadership. To create a new generation of revolutionary products and services, YIZUMI is committed to connecting European advanced die-casting technology, integrating global resources, building a China-Europe technology platform, and introducing European die-casting experts to overcome technical challenges together. At the same time, we cultivate the core technical capabilities of our Chinese engineers, from knowledge transfer to active creation.

YIZUMI employed a well-known industrial design company to craft the design of the new die-casting models. The goal of the LEAP design is to effectively integrate safety needs with functional requirements and offer an attractive visual appeal. YIZUMI`s aim is to ensure a great customer experience with our new LEAP product.

To establish strong in-house die-casting expertise, YIZUMI has invested heavily in its R&D and casting process capabilities. Our Product and Process Application Center (PPAC) offers a great platform to carry out diverse casting trials, mold sampling as well as casting process training. Close cooperation with carefully selected experts allows our team to be trained on casting processes and tool designs in order to provide our customers with the support they need to compete in their markets.

Further enhancing YIZUMI`s organizational capabilities, we partnered up European experts in various key technology fields. Close teamwork between these experts with our technical team generates the ability to look at engineering problems from different perspectives and find new, innovative solutions for the benefit of our customers.

Andre Dylong, General Manager of DSD, YIZUMI`s service partner in Europe, said: "We are proud to bring our more than 30 years of die-casting experience to this international project and it is exciting for us and interesting to work closely with the YIZUMI team.”

LEAP takes off

Benchmarking the top-line die-casting machines in the world

The word “LEAP” is not only the name for YIZUMI’s new generation die-casting machines but also demonstrates YIZUMI’s commitment to “Breaking the boundaries and overcoming our limitations to make YIZUMI a world top 3 company in our industry.”

The new generation LEAP series is the result of cooperation made possible between YIZUMI’s experienced international R&D team and YIZUMI`s technical team in China. The overall performance of the LEAP technology promises customers world class die casting.

As Wang Bo, the Product and Market Management manager of YIZUMI’s Die-Casting Division, said, "The new generation LEAP series features greatly enhanced injection performance with an intuitive HMI. The improved clamping system as well as our energy-saving drive group make LEAP an efficient, stable, and automated die-casting production unit. By using the independently developed Yi-Cast real time closed loop injection control system, LEAP guarantees the quality of every shot.”

The new generation LEAP die-casting machine features a 24-inch display, a 4-core i5 processor, a powerful industrial computer, and a Twincat 3.0 enabled visualization system. It is a machine with a smart "brain".

“The ORCA control system of the LEAP die-casting machine is sharp like a killer whale,” said Bo Wang. “Users can easily and effectively manage the key production parameters with the help of the ORCA control system, including speed, pressure, stroke, high-speed starting point, plunger resistance, pressure build-up time, injection stroke, biscuit thickness, vacuum level, clamping force, temperature, flow, etc., to improve the efficiency of machine operation and process quality.”

LEAP series die-casting machines can fulfill the requirements of semi-solid metal casting, magnesium alloy and aluminum alloys for high-end auto parts such as gearbox housings or structural parts. The first model of LEAP series die-casting machine launched is the 1250T. Other tonnages from 400T to 5000T will follow to complete the series.

Looking back, every generation of YIZUMI die-casting machines has always been a significant improvement providing great benefits to the global market. YIZUMI believes that its highly competitive position can only be retained through continuous innovation and creativity aiming at generating further benefits for our customers. At this moment, let us look forward to the takeoff of LEAP series die-casting machine in the new age!

More machine information:https://www.yizumi.com/cn/dcm/subprodetail/i2111589