【VIDEO】Yizumi MultiPro solution molding taillight cover

Abstract:

【VIDEO】Yizumi MultiPro solution molding taillight cover

Yizumi MultiPro solution can design modular systems of different types and sizes of injection units based on different product applications, so that multiple types of shots can be flexibly and quickly matched to meet the individual needs of the market, realizing double components, three components, and even special components, multi-component injection molding.

MultiPro solution has been widely applied in various industries, especially the automotive industry. Yizumi products has benn purchased by customers such as Shenzhen Silver Basis, Shanghai Yinghui and BYD etc., and used to produce two-color light cover, car seat decoration, car center console and other auto parts.

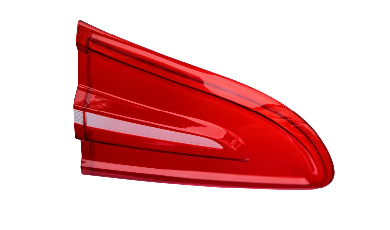

Two-color taillight cover application example

Based on years' of research and development of multi-component application, Yizumi launched the C series high-end multi-component injection molding machine. In the case, the UN550C-BTP achieved stable production of automotive two-color taillight cover in a 60-second cycle time, providing a cost-effective solution for stable molding and customization in the auto parts sector.

|

|

As a new generation of dual-component model, the C-series high-end multi-component injection molding machine brings more new value to customers:

Higher stability: 'Intelligent compensation technology for molding defects', intelligently adjusts the injection molding parameters, eliminates the effects caused by cavity inconsistency, and makes the molding stability higher, and the product weight repeatability is up to 1‰;

Higher turntable control accuracy: DCPC digital closed-loop positioning technology is adopted, the turntable action is fast and stable, no impact, accurate positioning, and the repeatability is ±0.001 degrees;

Better medium and low speed control stability: The system can achieve smooth injection at speeds below 5%, and the speed deviation does not exceed 5 ‰, which enables the low speed molded products to obtain a better molding process; The technology is more suitable for the molding of automobile lampshade, and It can effectively avoid the phenomenon that the product has stress, corrugation and difficult to adjust the fusion line due to the unstable injection speed;

Focusing on providing customers with high-quality multi-component injection molding solutions, in the future, Yizumi Headquarters will work closely with Yizumi Germany to develop camel-type shooting platforms and modular independent turntables for the application needs of European market, connect German advanced technologies and deepen the frontier applications of the MultiPro solution.