【Video】 Small and medium-sized precision medical device molding solutions

Abstract:

【Video】 Small and medium-sized precision medical device molding solutions

Today, plastics have huge market potential in the field of disposable medical devices, especially small and medium-sized high-precision medical plastic products.

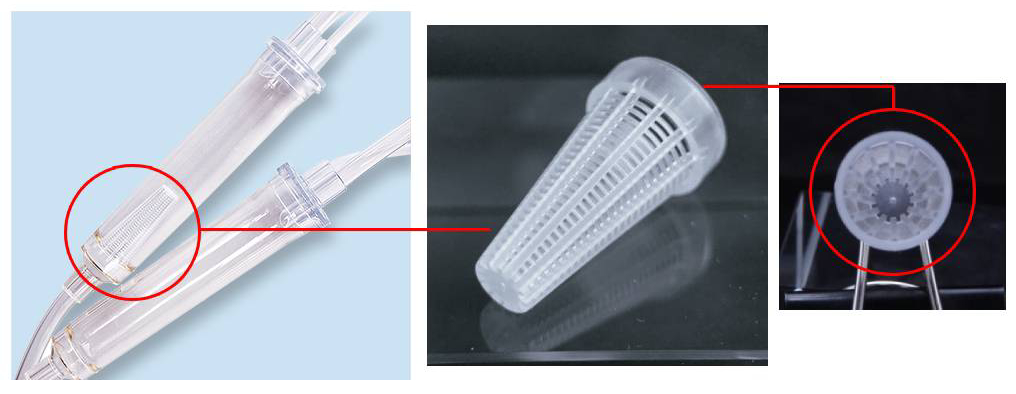

Yizumi electric injection molding machine molding medical blood pipe filter with a length of only 3cm. This product is one of the important product categories of Guangdong Baihe Medical Technology Co., Ltd. (hereinafter referred to as “Baihe Medical”). It is understood that the blood circuit mainly establishes the extracorporeal circulation channel during hemodialysis treatment, and the small part in the venous circuit, the filter net, needs to function to effectively filter the blood clot, thereby the position of the filter center hole and the grid The dimensional precision requirements are very high.

However, the effect of the traditional hydraulic injection molding machine on the production of filters has not been satisfactory, and there are problems such as shrinkage, unstable size, and lack of glue. With its high precision and high stability, Yizhumi FF series electric injection molding machine can easily solve the problem of filter forming and create cost-effective solutions for customers.

High stability

——High-rigidity integrated pedestal and line guide mechanism (IU500 and below)

High accuracy linear guide supports notably reduce the friction force on the plasticizing unit and increase the stability of plasticizing and injection pressure, resulting in stable part quality.

High precision

——The center of the movable platen is stressed and lightweight design

The design of the two platens is reasonable, the dry cycle is fast, the repeatability of the mold opening is high, and the parallelism of the template can be kept at 0.03mm, which is beneficial to the molding of high-precision products.

——Unique ServoDirect Control technology

Yizumi applies its own SDC (servo direct control) technology to movement control, so that the control system has nearly 20 times faster response time. The SDC technology also ensures the stability in injection, plasticizing and mold opening and closing accuracy.

Clean operation + intelligent manufacturing

In addition, Yizhumi FF series electric injection molding machine uses lubricating grease for automatic quantitative lubrication, which is easy to operate, reduces the risk of manual maintenance and machine failure, and meets the operation requirements of the dust-free workshop in the medical products industry. And in the new round of transformation and upgrading, electric injection molding machines help the medical products industry to achieve automated production. For example, the open external OPC port of the FF series can meet the needs of customer networking, real-time monitoring of the production data of the machine, and increase the automatic sorting function of the product through the micro-adjustment of the program to improve production efficiency.

application example

part

Medical blood tube filter

cavity

8

material

PP

size

Φ16 mm,H30.33 mm

weight

0.64g * 8

cycle time

10.9 s

customer profile

Guangdong Baihe Medical Technology Co., Ltd. is mainly engaged in research and development, production and sales of medical devices such as disposable medical consumables. The products cover medical consumables such as central venous catheters, hemodialysis catheters, needle-free infusion joints, and have been exported to more than 40 countries and regions around the world.

The above data comes from the workshop test