【Customer Story】Wuxi Langshion: Design the Future through light-weighting

Abstract:

【Customer Story】Wuxi Langshion: Design the Future through light-weighting

Leader in automotive lightweight metal molding solutions

Design only for the future.

In the field of automotive metal molding, what empower theengineers to touch the future are the lightweight structures. However, there isonly a handful of enterprises that are making such dedicated investment. WuxiLangshion is one of the few.

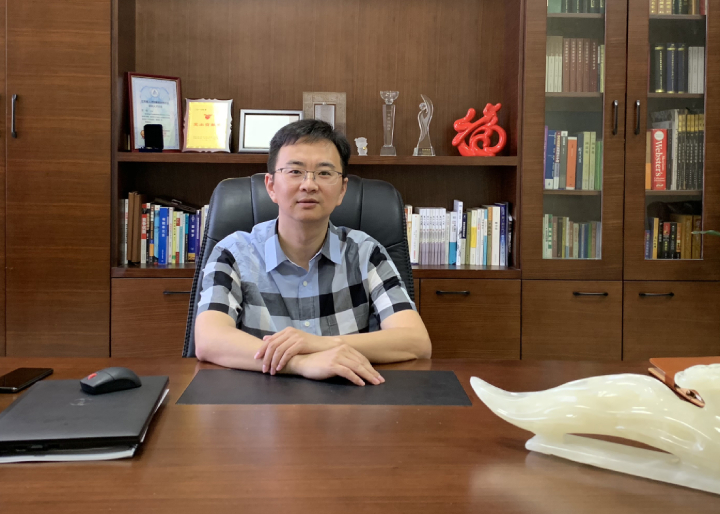

Founded in 2013, Langshion is the first domestic company thathaving its primary business focused on thermoforming, hydraulic forming,aluminum-magnesium die casting, and other lightweight automotive molds andproducts. Devoted to the R&D of automotive lightweight metal forming, thecompany’s founder and managing director, Dr. Yang Chen has applied for 110patents.

In the die-casting industry that has undergone development for morethan 50 years, Dr. Chen does not wish to follow the old track. Since its establishment,Langshion has focused on lightweight technology and rapidly created anintegrated operation model covering product design, R&D, and massproduction. Its operating revenue has doubled for five consecutive years,supporting customers including Geely Automobile, Shanghai GM, Mercedes-Benz,BMW and other brands.

Magnesium alloy instrument panel bracket

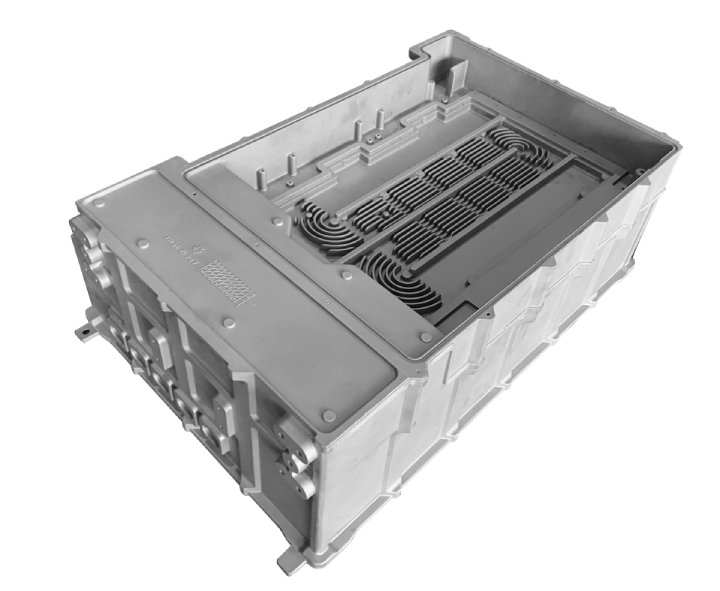

EV battery housing

Shock tower

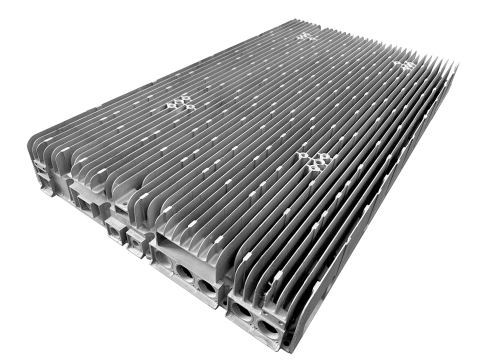

5G base station filter

Top-down lightweight design pattern

Lightweight is an eternal theme in the automotive industry. Withthe development of the automobile industry, the investment in lightweight bynew energy vehicles is more vigorous and faster than conventional fuelvehicles. “As the battery itself in the new energy vehicles is very heavy andwill affect its range, weight reduction becomes a rigid demand.” said Dr. YangChen. Currently, the weight reduction budget to the parts and components in thenew energy vehicles will not be less than 30 yuan/kg -- that is, for reductionof each kilogram of product weight, the manufacturers are will to pay 30 yuan (approx.4.35 USD) more.

Whether it is new energy vehicles or conventional fuel vehicles,the way to reduce the weight of the cars is nothing more than the developmentof lightweight new materials, optimizing product structures, and improving themanufacturing processes. The latter reflects the core technology of Langshion-- to achieve the lightweight of products with its strong product design anddevelopment capabilities as well as strict control over manufacturingprocesses.

Starting from the beginning of a product, Langshion designs theproduct according to customers’ requirements (weight reduction, rigidity,post-collision quality, etc.) and develops the mold independently. Rather thanoutsourcing, the company has always kept the mold manufacturing in their ownhands through closed-loop management.

“We build our business around molds. Mold development is somethingwe are really good at.” Dr. Chen said that Langshion’s mold team consists ofmore than 200 people. The core membersof the team are all from Fortune 500 multinational large companies with yearsof experiences in mold R&D and manufacturing. Currently, Langshion’sproduction capacity in mold business has exceeded 300 million yuan (approx. USD43.6 million) and is in the leading among the domestic counterparts.”

More importantly, through designing and making its own productionlines, developing high-vacuum die-casting technology, and jointly developingcore components with equipment supplier (Yizumi), Langshion has successfullyachieved weight reduction in the process. “From product design, molddevelopment, to manufacturing, we always adhere to a top-down design approachto keep the key aspects of the work in our own hands.” said Dr. Chen.

Langshion can now independently optimize theentire product life cycle and rapidly respond to customers’ demand. At present,Langshion has completed several large-scale lightweight structural itemprojects under this operation mode, including instrument panel, shock tower,on-board instruments, lifting door, and battery holder for new energyvehicles.

Chen Yang, General Manager of Wuxi Langshion Lightweight Technology Co., Ltd.

Reducing weight by 50%, the company focuses on lightweighting of large die casting structural components

Large structural components with large projection area such asbattery case or with large frame structure such as instrument panel bracket,large tonnage equipment is generally required to meet production needs. Inaddition, to ensure product strength and toughness, it is also necessary tomake breakthrough in high vacuum die casting, mold sealing, temperature fieldcontrol and other technological areas.

In Langshion’s lightweighting plan, he chose to use the high vacuumdie-casting technology and the heavy duty die casting machine made by Yizumi.“We have maintained a strategic partnership with Yizumi in the effort toachieve a high vacuum die casting solution. Also, Yizumi’s heavy dutydie-casting machine is doing a great job in terms of improving productivity andoperation stability.” said Yang Chen. Since 2017, Langshion has purchase from Yizumi the H series 4000-ton and2500-ton heavy duty die casting machines and the automation solution. It hasnow produced steadily a number of large aluminum-magnesium alloy die-castingstructural parts.

Yizumi H series 4000t diecasting cell in stable operation at Wuxi Langshion

As one of the few domestic companies that really possess the coreand original technology in aluminum-magnesium high vacuum die-casting field, Langshion’saluminum-magnesium alloy die-casting products generally can reduce the weightof a component by 50% (compared to the traditional part made of steel).Moreover, its products are not limited to the automobile field. In recentyears, Langshion has been involved in the development in aerospace andcommunication fields to diversify the application of large-scale die-cast, suchas the nearly a meter long, thin-walled 5G filter housing and radiator housing.At present, these products have completed the commissioning on Yizumi’s Hseries 4000-ton heavy duty die-casting machine and are about ready for volumeproduction.

Today, Langshion has become the the leading supplier of high vacuumaluminum-magnesium alloy die-casting structural components to a number ofmainstream manufacturers. Talking about the future planning, Dr. Chen said thatLangshion will continue to expand the scale effect and adhere to thedevelopment of lightweighting technologies.