Online Open Week| Fan Frame•DirectPro Long Fibre Direct Injection Molding

Abstract:

Online Open Week| Fan Frame•DirectPro Long Fibre Direct Injection Molding

Long fibre reinforced plastics are widely used in automotive industry. However, the industry has been facing with problems including high-costing granule, scarce fibre content and insufficient fibre length, which were hampering the automotive process development. YIZUMI DirectPro Long Fibre Direct Injection Molding can replace fibre-reinforced engineering plastics, simplify manufacturing techniques, reduce material cost, improve the product mechanical property, and help the automotive industry receive higher profits due to cost reduction.

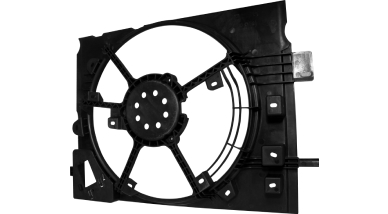

During the YIZUMI Wujiang Factory Open Week, DirectPro-DIM will display fan frame production process. UN1000DP two-platen injection molding machine is equipped with continuous fibre metering feeding device to realize long fibre direct injection molding process:

1.Fibre breakage is greatly reduced. The fibre length of finished product increases by 50% compared with those made of long fibre granule;

2. Mechanical properties and strength of the product have improved. It can replace long fibre granule and reduce production cost by 30%-50%;

3. Adjust fibre length (5-100mm), content (0-50%), and material combinations according to different product requirements;

4. Optimized based on standard machine, the technology can be applied to standard injection molding processes.

| 制品名称:

|

| Cavity: 1 |

| Material: PP(Sabic 513MNK40T) Glass fibre(CPIC ER4305PM-2400) |

| Size(L x W x H): 540 x 425 x 85mm |

| Weight:

|

| Cycle Time:

|

| Partner: |

|

*The data above were acquired by testing in the factory, only for your reference. The specific data please refer to the actual equipment.

The preview of YIZUMI Online Open Week will keep updating, stay tuned!