【Online Open Week】”Soft-touch Polyurethane + Injection Molding” One-step Approach for Prefect Surface

Abstract:

【Online Open Week】”Soft-touch Polyurethane + Injection Molding” One-step Approach for Prefect Surface

ReactPro IntegratedSolution of Polyurethane and Injection Molding is jointly developed by YIZUMIand FRIMO Germany, it will bring more possibilities for the popularization of premiumand multifunctional surfaces such as automotive interiors, 3C and homeappliances in a more innovative and economical way.

How ReactPro Works

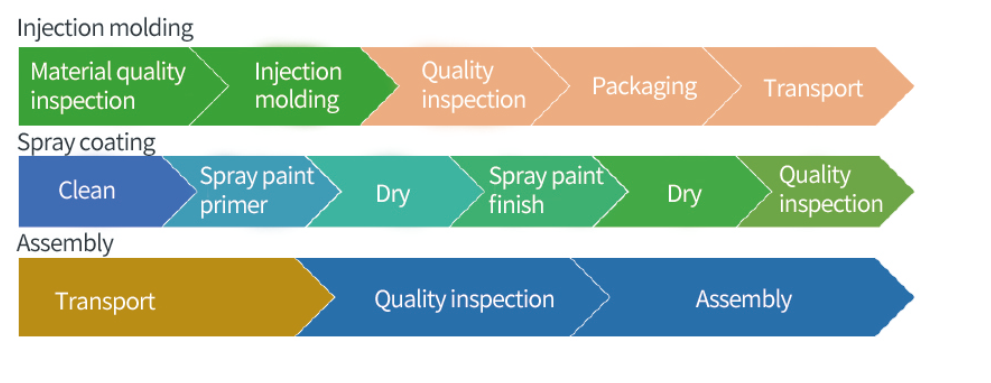

Traditional interior production Processes

Soft-touch Polyurethane and Injection Molding One-step Approach for Prefect Surface

During the YIZUMI Online Open Week, YIZUMI ReactPro will further display one-step-molding “Soft-touch Polyurethane + injection molding” by producing engine cover with polyurethane surface on site. Various surface effects including soft-touching, self-repair, high-gloss surface, matte effect, 3D depth are available. In regard of polyurethane that widely used in automotive industry, YIZUMI ReactPro solution makes more changes for design: products can be transparent, can be colorful, even if there are scratches on the surface, they will disappear in few hours at room temperature.

ReactPro Value Advantages:

One-step molding “Polyurethane + injection molding”, short cycle time, high efficiency and low cost

Multifunctional, one equipment is suitable for different polyurethane molding finishes, such as high-gloss, scratch resistance, self-repair, soft-touch, etc. It is flexible, intelligent and efficient.

Injection molding + 3D printing, effective combination of large-scale manufacturing and customization

| Application:Engine Cover |

| ReactPro Integrated Solution of Polyurethane and Injection Molding |

| Size:400 x 350 x 25mm |

| Weight: 475g |

| Cavities: 1+2 (InPUR) |

| Base: |

| Material:AKROMID? RM-D GF20 |

| Volume:336cm3 |

| Wall Thickness:2.5mm |

| PU Layer: |

| Material:SHGPuR |

| Volume:15cm3 |

| Wall Thickness:0.6mm |

| Equipment |

| Injection Molding Machine:YIZUMI 500DP |

| PUR Equipment:FRIMO EPOx Mix |

| Automation:Yizumi |

|

|

|

|

|

|

※The Data above were acquired by testing in the factory, only for your reference. The specific data please refer to the actual equipment.