【k-zeitung】Injection moulding with PUR flooding rethought

Abstract:

【k-zeitung】Injection moulding with PUR flooding rethought

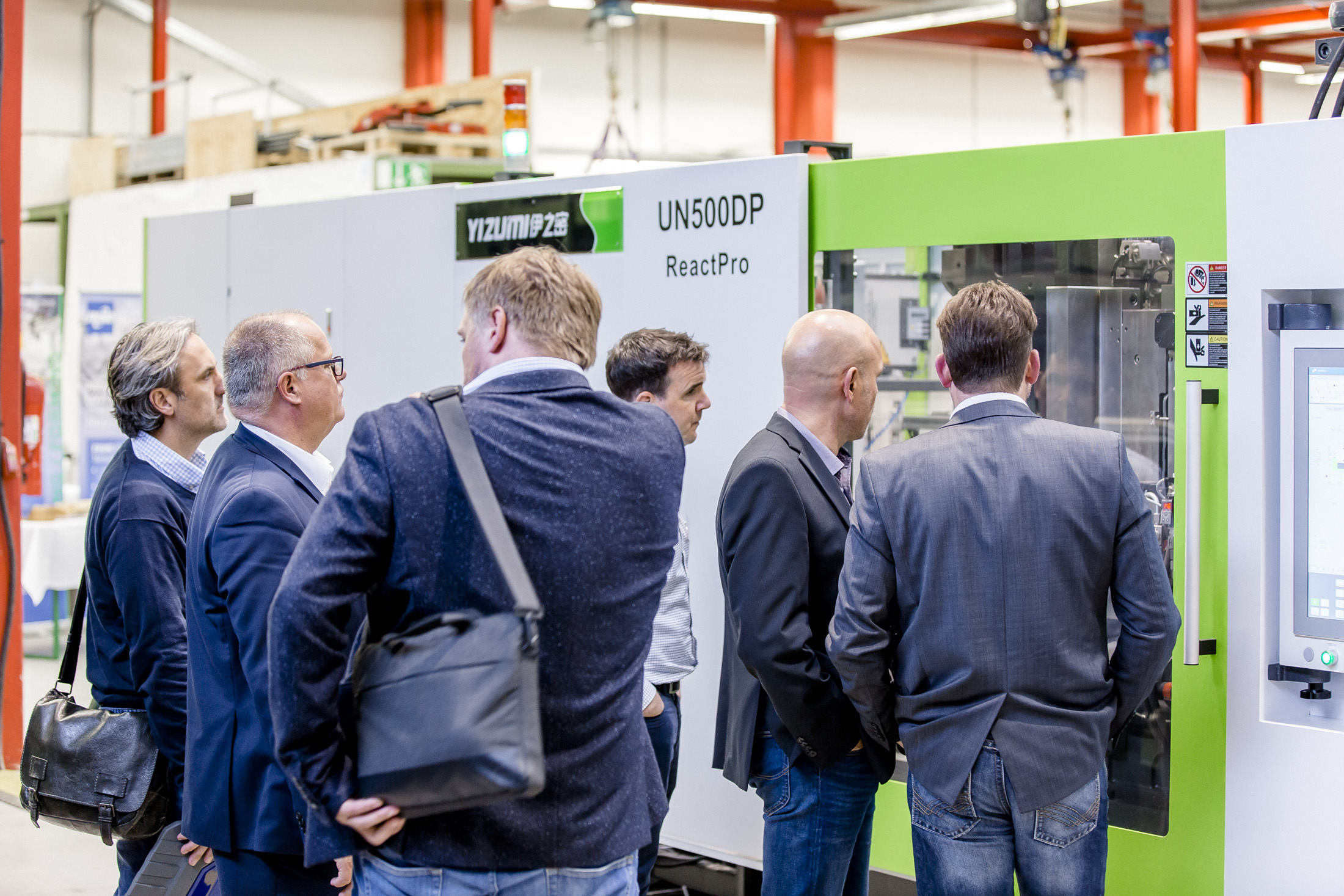

The Frimo Innovation Day demonstrated how injection moulding and PUR flooding can be intelligently combined.

Simpler, more modular, more flexible, more cost-effective: this is what the cooperation partners Yizumi and Frimo offer, combining injection moulding (Yizumi) with polyurethane (PUR) flooding (Frimo) and now marketing the whole thing under the name "ReactPro". At a joint Innovation Day at Frimo in Lotte at the beginning of November, interested trade visitors were able to take a look at the first integrated and automated ReactPro system, which produced a polyamide engine cover with PUR flooding as a demonstrator live on site.

PUR flooding replaces painting

Injection moulding with PUR flooding replaces the subsequent painting of thermoplastic components. This combination combines the economical production of injection molding with the appealing haptics and appearance of polyurethane. In this way, visually high-quality components can be produced quickly and inexpensively in a single process step without any reworking.

Smartly combined

PUR flooding with injection moulding is not new, but according to Jürgen Mauss, Key Account Manager at Frimo, there are so far only special machines on the market that represent a comparatively high investment and cannot be converted for other purposes. "The ReactPro concept is based on a slightly modified Yizumi standard injection molding machine with a Frimo PUR metering unit attached to it. This modular system can be separated again and the injection moulding machine and dosing machine can then be used for other purposes," explains Mauss at the Frimo Innovation Day.

Benjamin Wessling, Head of Polymer Processing at Yizumi, added: "If you already have a Yizumi injection molding machine in operation and want to flood thermoplastic components with polyurethane in a new project, simply ask our partner Frimo for the right dosing system. The polyurethane unit can then be coupled relatively easily to the injection molding machine. With only a few steps we enable a standard injection moulding machine to flood with polyurethane." Wessling sums up the difference as follows: "Instead of a large, complex and expensive special machine that can only handle a single process, we cleverly combine a standard injection moulding machine with a PUR dosing machine that has been adapted to the process".

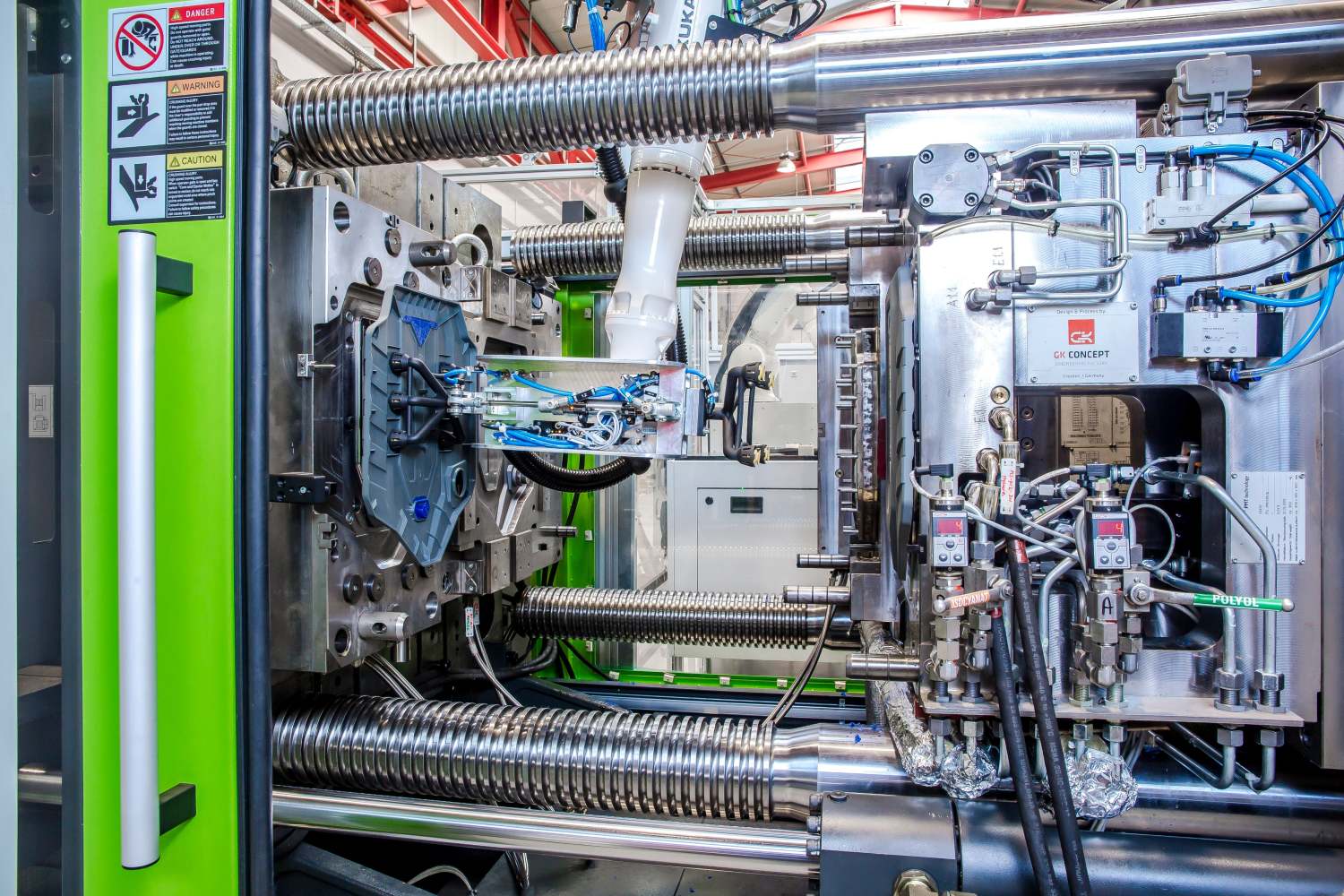

Tool without swivel unit

A new tooling technology contributes to the success of ReactPro. Yizumi trusts in its long-standing partner GK Concept, who developed a new tool for combination technology. "The new InPUR mould works without a swivel unit, instead we have placed two PUR moulds directly next to the thermoplastic mould", explained Roger Kaufmann, CEO at GK Concept. "The first injection-moulded thermoplastic carrier is then transferred by a robot into one of the PUR moulds." This transfer technology of the In-PUR mould concept offers advantages over conventional mould technologies with a swivel unit: In addition to direct cost savings, the installation space is reduced and a small mould height allows the use of smaller machines.

PUR flooding in the injection moulding cycle

The new concept also wins in terms of cycle time. In the case of swivel units with one PUR and one thermoplastic tool each, PUR flooding delays the process if the thermoplastic carrier has a geometrically simple structure because the longer curing time of the polyurethane can then be a limiting factor. Various application examples and the component from the live demonstration, in which the flooding step runs in step with the injection moulding carrier, show that this does not necessarily have to be the case. However, if the curing time is the limiting factor for certain applications, the presented mould concept with two PUR moulds in which a finished thermoplastic carrier is alternately flooded in the subsequent cycle is the ideal solution. "This means that we can also process PUR materials with long reaction times in the cycle of the injection moulding machine," explained Kaufmann.In addition, the tools are designed in such a way that exactly only the desired areas are flooded with PUR, eliminating the need for further reworking.

Plastic ideas for multi-components

The process requires competencies not only in the areas of injection moulding machines, polyurethane systems and mould technology, but also automation and the respective materials play a decisive role. Yizumi and Frimo chose SAR for the automation and the polyamide specialist Akro-Plastic and PUR specialist Rühl Puromer as material partners. "A perfect product can only be created if all raw materials are matched to each other," explained Thilo Stier, Director of Sales and Innovation at Akro-Plastic, and emphasizes: "When choosing the right thermoplastic, care had to be taken to ensure that the material distorts only minimally, as the process only permits small tolerances. It was also necessary to find a material that adheres well to polyurethane. Timing in the process is also important, so amorphous polyamide adheres better than crystallized polyamide."

After tests with different formulations, the choice finally fell on the 20% glass fibre reinforced polyamide Akromid B3 GF20 2 RM-D Natur (4164) from Akro-Plastic. On the PUR side, Puroclear from Rühl was used. Dr. Ingo Kleba, Managing Director at Rühl Puromer, gave visitors to the Frimo Innovation Day an insight into all the things that can be done with PUR today: "An ongoing current topic is the surface finishing of components by flooding them with polyurethane coatings, both as clearcoat and in color. In addition, there is the combination with the almost limitless design variance of foils and the integration of functions and light. The degree of gloss, suitability for everyday use and scratch resistance of the surface are getting better and better," he explained. A decisive factor for the efficiency of the PUR flooding technology, especially when combined with injection moulding, is the excellent self-separation of modern Puroclear systems, which makes the application of otherwise common external release agents or a special tool coating unnecessary," he continued. He was particularly proud of PUR formulations with self-healing properties: "If a scratch should appear on the surface, it will disappear within a few hours at room temperature.

Additive manufacturing integrated into the process

Additive manufacturing can also be seamlessly integrated into the process. At Frimo Innovation Day, an additive manufacturing cell printed a reinforcement structure on the engine covers using Fused Layer Modeling (FLM). A granulate of the carbon fiber reinforced polyamide Akromid B3 ICF 30 9 AM black (7451) was used. According to Thilo Stier, "extremely high strengths are possible here because the carbon fibers align themselves preferentially in the direction of application".

The summary of this demonstration in the Frimo TechCenter is: The whole process requires competences in different areas. In addition to the injection moulding machine, the polyurethane plant, the additive manufacturing and the automation, the mould technology and the respective materials play a decisive role. "Our network of different partners has combined the different technologies into an integrated process in a smart, modular way. A perfect product can only be created if all areas are perfectly coordinated," concludes Benjamin Wessling of Yizumi.

(Courtesy of k-zeitung)