Successfully put into production! Yizumi's 1,250-ton thixomoulding machine at German customer

Abstract:

Successfully put into production! Yizumi's 1,250-ton thixomoulding machine at German customer

After the successful development of the MGII thixomoulding machine series with a clamping force of 650 ton (6,500 kN) in 2015, Yizumi has made another breakthrough in the production of large thixomoulded magnesium alloy components.

Together, the engineers from Yizumi China and Yizumi Germany have developed a thixomoulding machine with a clamping force of 1,250 ton (12,500 kN) making it the world's largest thixomoulding machine to date.

The machine was built in early May 2019 at castwerk in Frankenberg (Germany) and is in operation.

castwerk GmbH & Co. KG in Frankenberg (Germany) belongs to the global Hettich Group and produces components with magnesium pressure die-casting and magnesium thixomoulding for the automotive and e-mobility sectors.

As of the end of 2019, the new 1,250 ton thixomolding machine will be used as standard for the chassis for the new e-scooters, which will expand the e-mobility market in Europe over the next few years.

It was crucial for castwerk's end customer and project management that the component for the innovative E-scooter is very light, yet offers the highest level of safety and driving stability. For this purpose, the thixomoulding machine must be able to guarantee process-reliable manufacturing. The first pre-series productions show that the machine meets these requirements.

In recent years, castwerk has been involved in the production of large magnesium alloy components for the automobile and urban mobility sectors. Due to the small clamping force and injection volume, the thixomoulding technology and hot-chamber die casting machines available in the past were barely able to gain a place in these industrial sectors on a large scale.

With the existing thixomolding machines having a maximum clamping force of 650 ton (6,500 kN) and a maximum shot weight of 1.5 kg, only a few products could be produced that met the requirements of the automotive and urban mobility sectors.

Therefore, castwerk decided in late 2017, together with Yizumi, to discuss a thixomolding machine with higher performance parameters and then ordered a new thixomoulding machine with a clamping force of 1250 ton (12,500 kN) and a shot weight of up to 2.8kg.

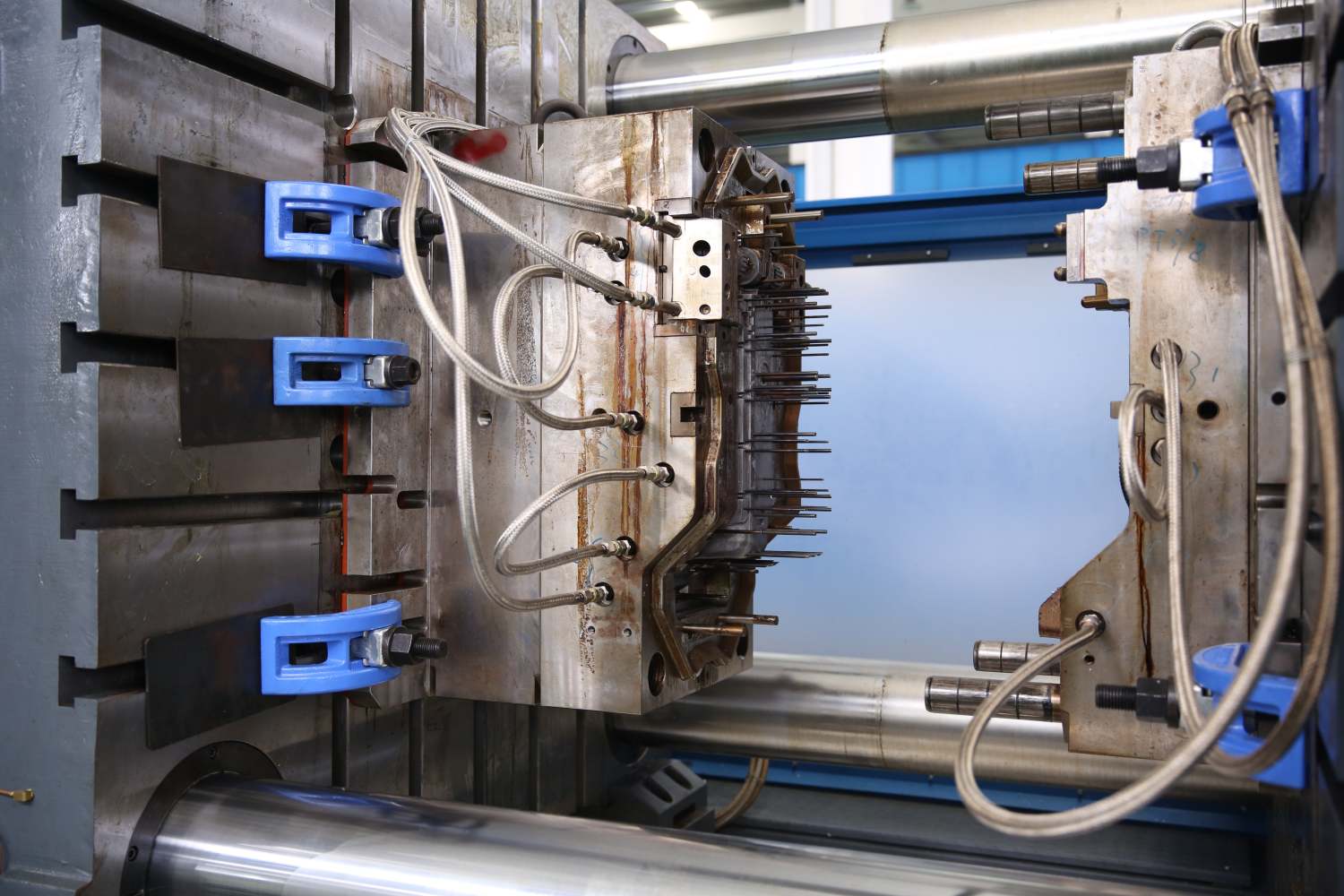

In December 2018, the 1,250 ton thixomolding machine underwent its first tests with the new hot runner technology integrated in the tool at the YIZUMI Wusha plant in Shunde.

At the end of 2018, a team from castwerk Germany observed the machine’s test run. The success of the first test impressed the castwerk employees. From tool testing to customer installation and commissioning, Yizumi sent a team of engineers to ensure comprehensive monitoring throughout the process.

The technical manager, Siegfried Schneider, said: “We receive a lot of requests for large cast parts. Customer demand continues to grow. The Yizumi machine will allow us to meet the needs of our customers”.

As well as the chassis for the new E-Scooter, castwerk also designs large driver cockpits, so-called display composite elements, for vehicles.

Here, too, castwerk has decided in favour of thixomoulding technology and is in talks with its partner Yizumi about the next big step in thixomoulding technology: the construction of a 2,000 ton thixomolding machine.

Thixomoulding machines are common for the production of thin and lightweight 3C products such as mobile phone base boards, protective covers for PC housing, etc.

Yizumi masters the two core technologies in thixomoulding, high-speed injection control for injection speeds of up to 5,000mm/sec and the production of injection units for processing magnesium alloys. As part of the developments, a large number of inventions and new patents were created. Yizumi’s successful development of a thixomoulding machine with a clamping force of 1,250 ton (12,500 kN) and a shot weight of up to 2.8 kg sets a new standard in the sector.

With the rapid growth in the market for electric cars and new electric mobility vehicles in the urban mobility sector, Yizumi is certain that the new thixomoulding machine for lightweight components will help to break new ground in many industries.

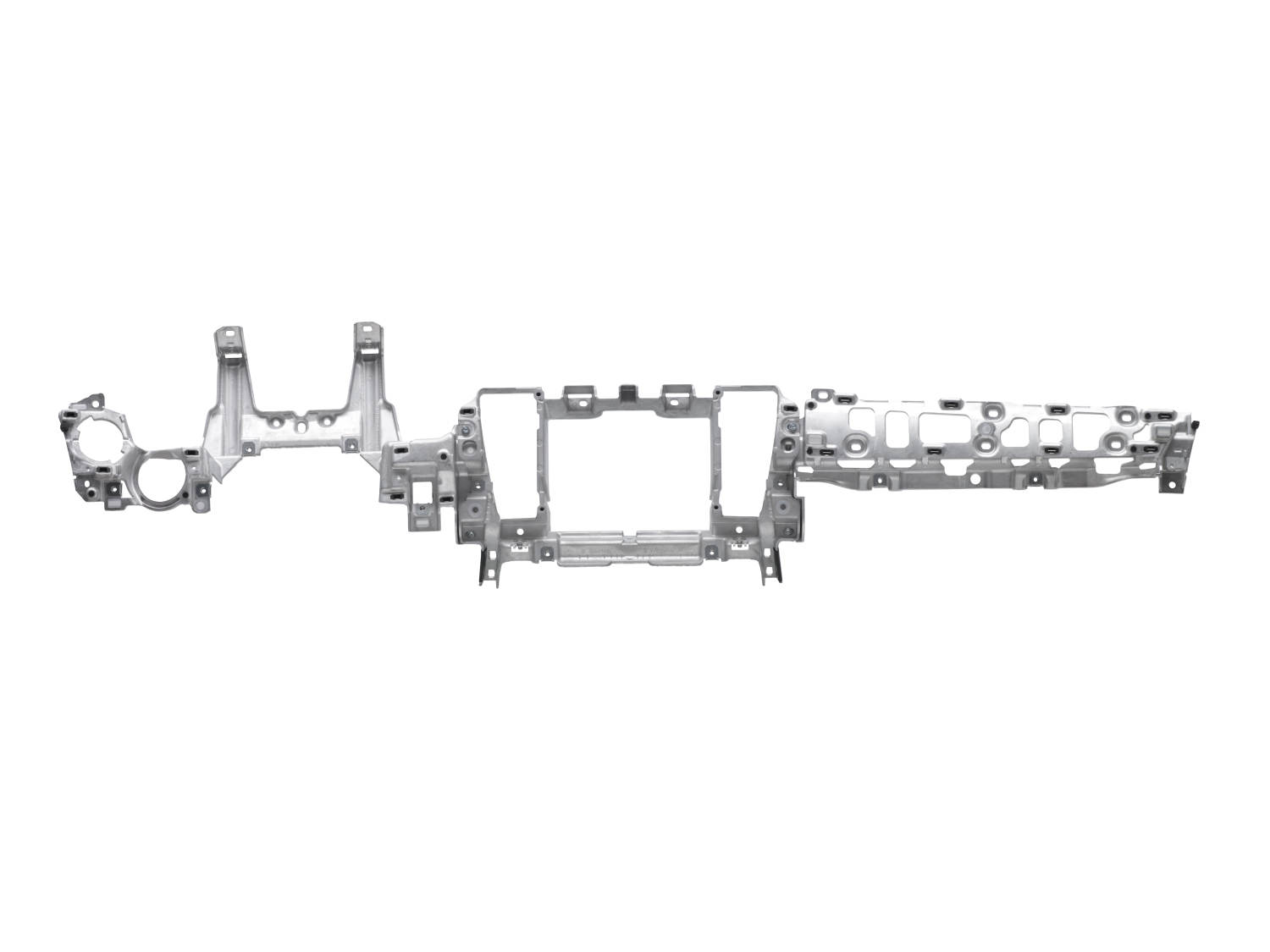

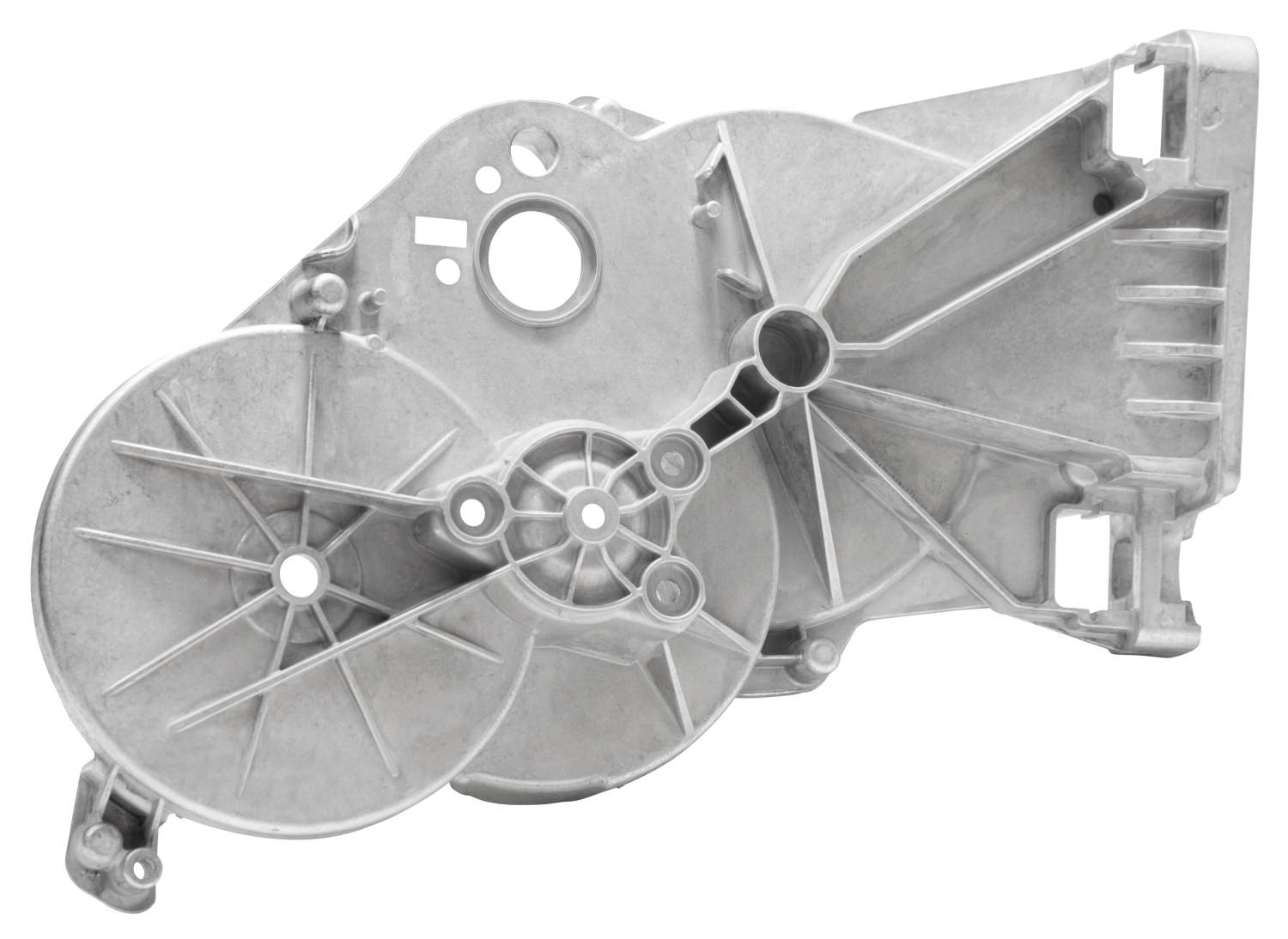

castwerk products

|

Component: Chassis for electric scooter Measurements: approx. 550mm*140mm*153mm Weight: approx. 1.2kg Wall thickness: up to approx. 4mm |

|

Component: Porsche Panamera instrument panels Measurements: approx. 1100mm*300mm*200mm Weight: approx. 1.9kg Wall thickness: up to approx. 3mm |

|

Component: Daimler Benz gear box push rod housing Measurements: approx. 240mm*110mm*50mm Weight: approx. 330g Wall thickness: up to approx. 2.5mm |

|

Component: Porsche Macan hinge for arm rests Measurements: approx. 300mm*170mm*90mm Weight: approx. 390g Wall thickness: up to approx. 6mm |