Foam Injection Molding – more than just bubbles

Abstract:

Foam Injection Molding – more than just bubbles

Foam injection-molding sounds like a well-known technology and since many years introduced into the market. Indeed a large number of molders mainly in Europe and North America are using this technique to generate physically foamed parts. Thereby the process of thermoplastic foam injection molding (FIM) is not used in the branch of automotive alone. Also among the producers of electronic components and partly in the area of white goods or home appliances FIM is established. However, when applying the physical foaming process, the part design engineers need to consider at the beginning of the part design the major aspects of FIM component design. That relates into a different tool design compared to tool design for compact components! Only then, they can benefit from the entire potential of this special process. Due to this reason a lot of molders in China, which already have some experience based on foam injection molding trials with molds, designed for compact components, are talking with reluctance about this process.

Also the introduction of the FIM technology in the western countries was a long and rocky path of research and development work. Nowadays the former niche application especially in automotive has gone over into a reliable large series production process. Due to the high advantages compared to compact part design, we predict the FIM process will be a standard process in the next coming years for all molders over the world.

Talking about the lightweight design trend, foam injection molding is the first step into this field! The high number of beneficial properties affecting the part and the molding process in a very favorable way. The technique is the best choice for applications requiring high dimensional stability in weight optimized structures or components with the following advantages:

• Low warpage

• No sink marks in case of thin wall parts

• Lower melt viscosity with higher flow ability of the melt

• Low mold pressure compared to compact design

(Figure: Trexel) Washing mchine cover plate company Miele

In the case of a washing machine cover plate on the left, the molder reaches a total weight saving of more then 30%. App. 10% was reached by the foaming, more then 20% was related to the new component design following the design rules of FIT. To fully undestand this, the designer needs know-how about the process basics.

Mainly three basics have to taken into account during part design: First: We have no usual warpage compared to compact molding, because pressure build up in the cavities is is perfectly homogenious due to foam expansion. Second: The foam is generated as an integral foam and the parts can be designed according to the demands of load and low weight. Third: Due to the lower viscosity based by the blowing agent the design can be executed with higher flow path / wall thickness ratios.

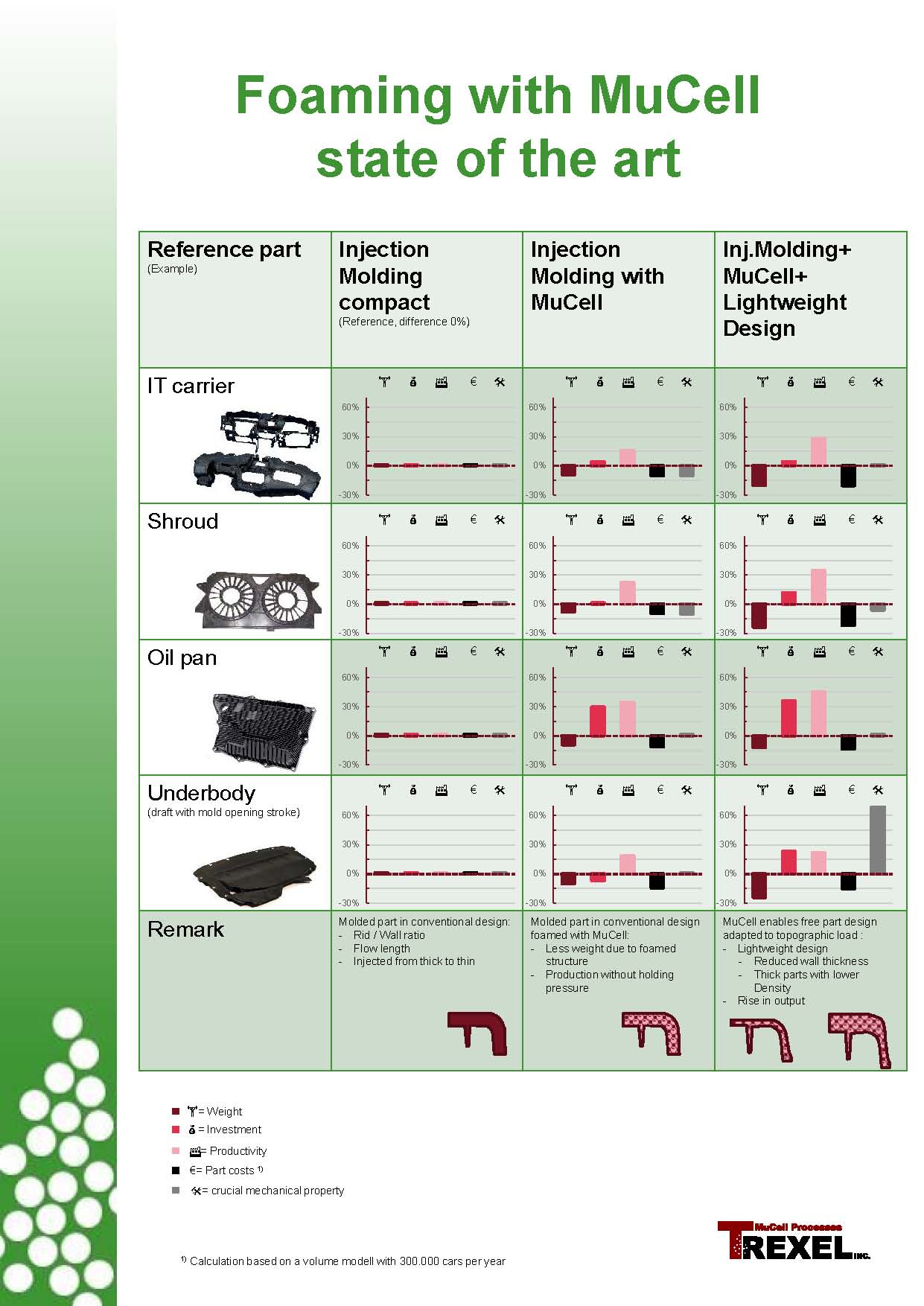

The next figure shows the potential of the foam injection molding process compared to compact molding. The chart shows additionally the big influence of the part design – called lightweight design –and in all cases a significant cost saving!

(Figure: Trexel) Foaming with MuCell – state of the art

Trexel developed the so-called MuCell process of physical foaming since 20 years and is a technology partner of Yizumi.The figure shows the state of the art of European injection molding machine manufacturers.

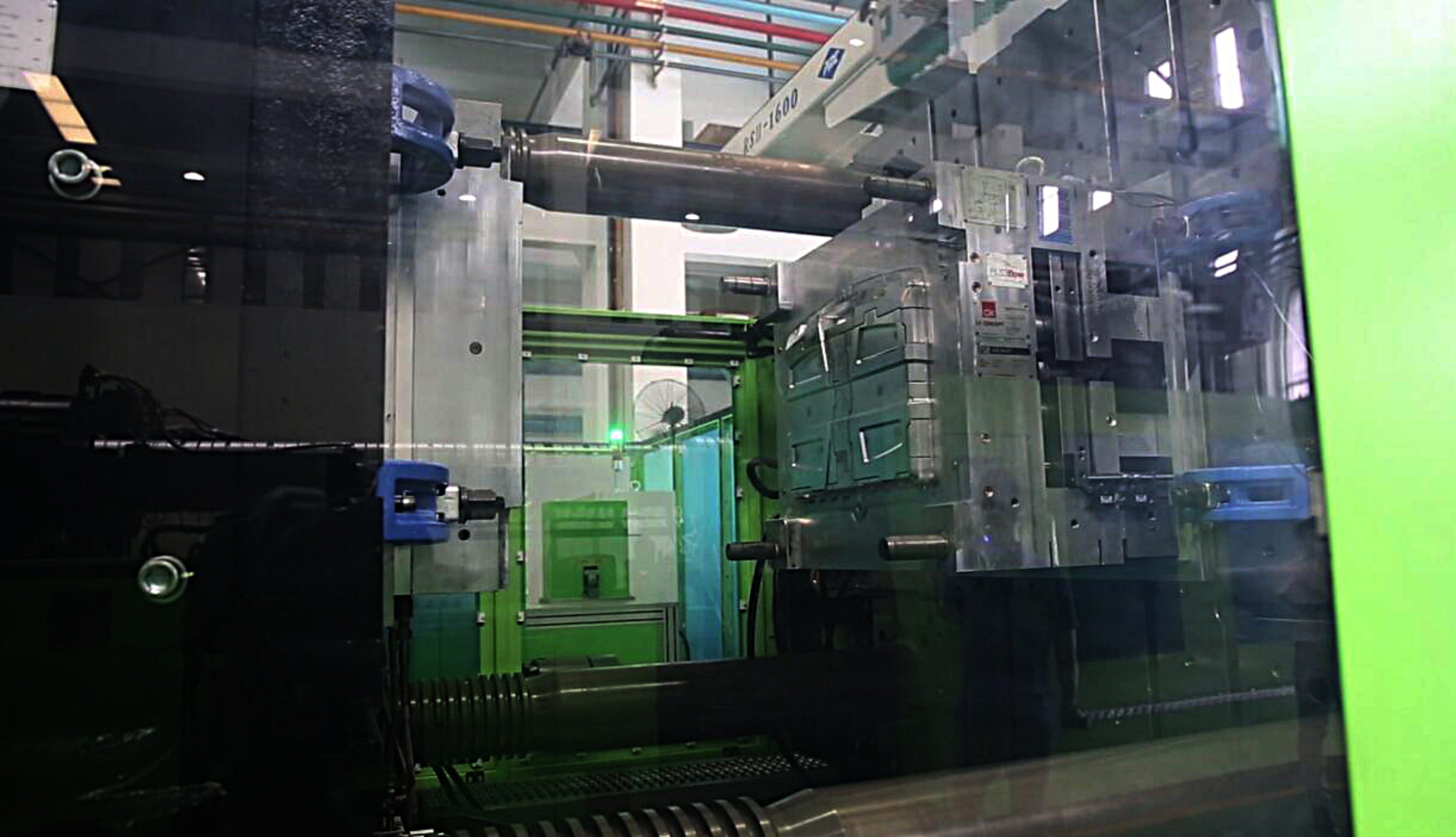

Yizumi showed the newest development in FIT with additional advantages concerning cycle time reduction at the last Chinaplas: The main step into a significant cycle time reduction compared to the state of the art FIT (see figure above) was based on Aluminum mold design. Due to the low cavity pressure of the FIT process, Al is a suitable material for tools for foam injection molding. The cycle time reduction compared to steel molds can be in some cases up to 50%, based on the much better heat transfer coefficient, which effects the cooling time of the part. A ceramic layer at the surface of the mold compensates the disadvantage of higher wear in case of Al. Our technology partner Weimat in Belgium close to our newly founded development center in Germany built the tool. The cost savings are fundamental: The Al tool is much cheaper than a steel mold and can be machined faster. The significant cycle time reduction relates to lower part costs.

Figure: YIZUMI's DP series machines teaming up with aluminum alloy mold manufacturing toolbox

As conclusion, the process of physical foaming offers a wide range of cost savings with the technology advantage of lightweight design. To achieve this the part designer has to understand the basics of FIT mentioned above. The system of Al tool, a special foam injection molding machine and the MuCell technology is offered by Yizumi as well as assistance in part design to reach the best cost reduction at high quality level of the application.

(Article written by Dr.-Ing.Hans Wobbe)