Application Highlights

Low density

The lightest of the commonly used metals.

High specific strength

Higher than that of aluminum alloy and steel.

Physical performance

Good corrosion resistance, electromagnetic shielding properties, radiation resistance, high-precision mechanical processing, and good thermal conductivity.

Good casting performance

The melting point of magnesium alloy is lower than the specific heat capacity and latent heat of phase change. With lower melting energy consumption, faster curing speed, and lower dynamic viscosity, the magnesium alloy can perform well in die casting and maintains its dimensions.

Strong torsion resistance

Start cracking until 336° twist during the torsion test.

Strong electromagnetic shielding performance

The electromagnetic shielding performance of all electromagnetic frequency bands is better than aluminum alloy.

Good vibration and shock resistance

Superior to cast iron and aluminum alloy in terms of damping coefficient, vibration energy absorption, and vibration dissipation.

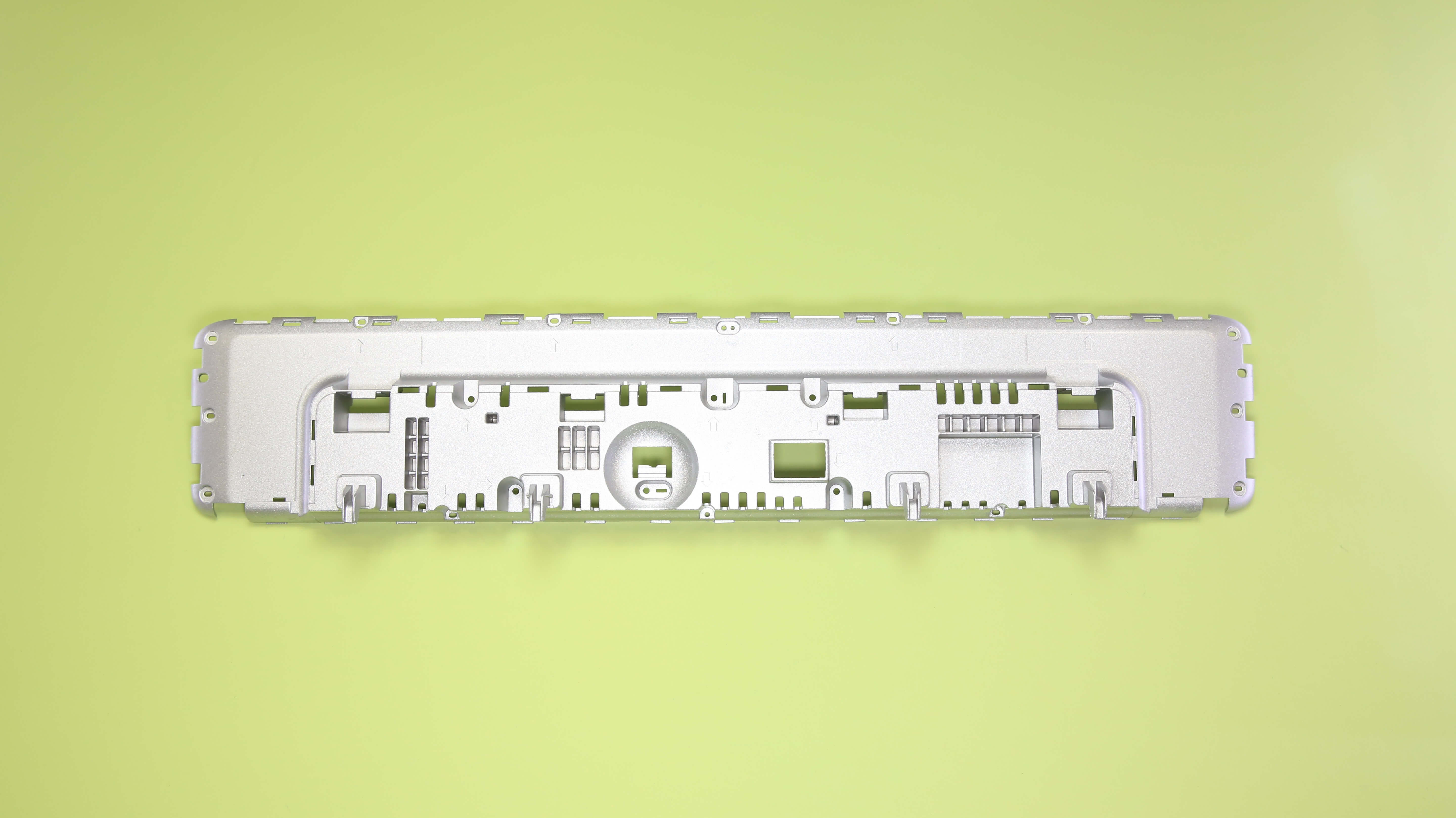

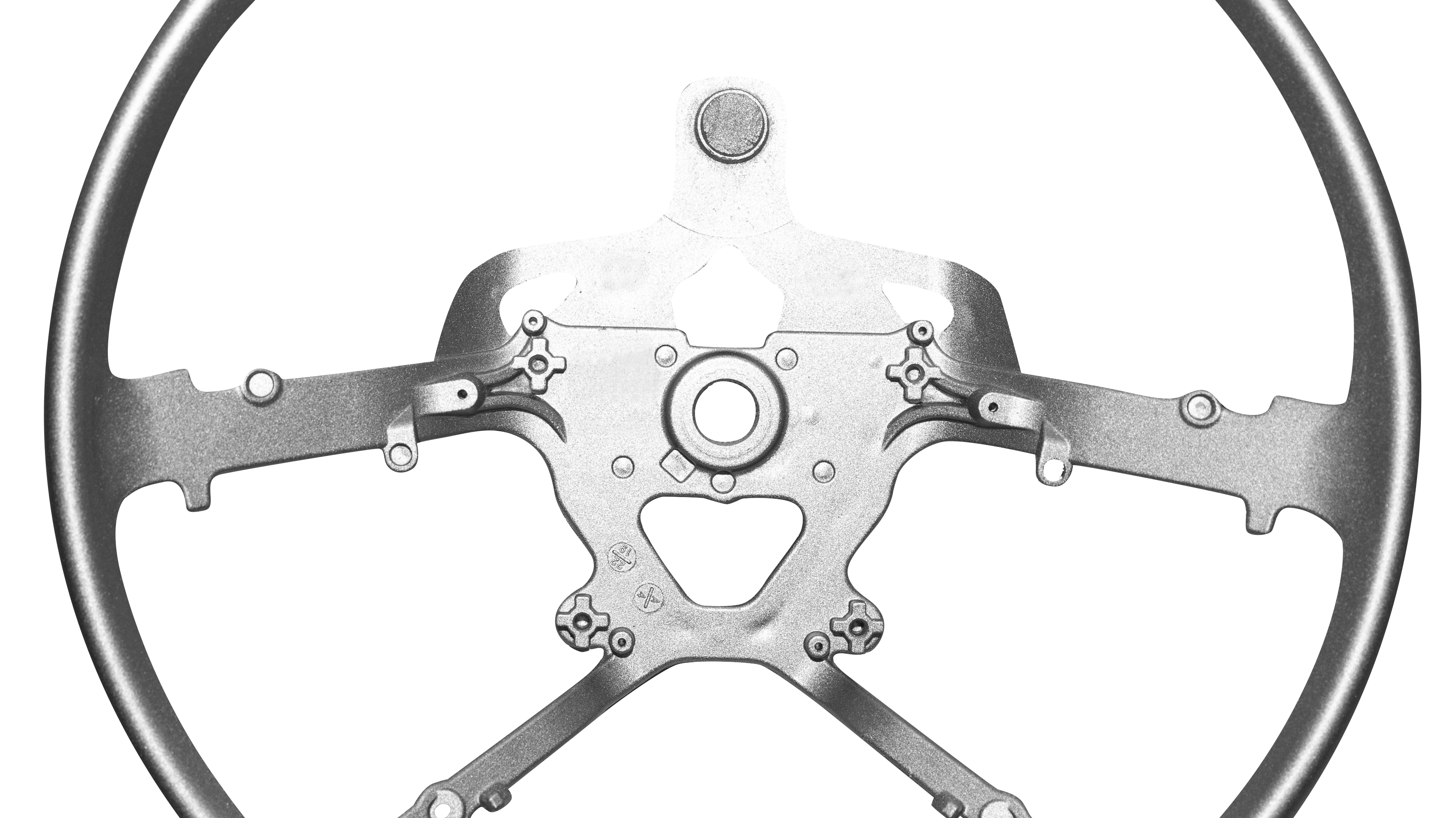

Interior Parts Application

Product Video

Service Process

- Raw materials selection

- Product design

- Mold flow analysis

- Mold design suggestion

- Product performance

- Product quality

- Ease of use

- Safety requirements

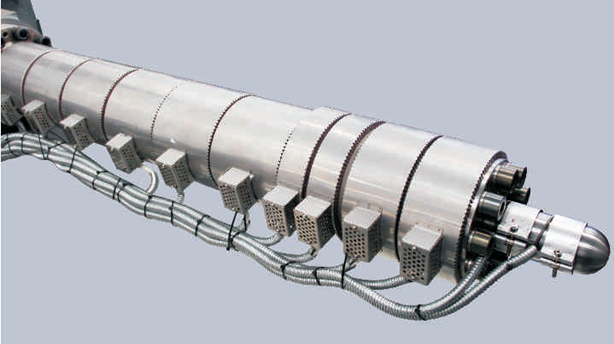

- Planning of production line

- Arrangements for people, machines, and materials according to process flow

- Peripheral automation

- Smart connection

- Professional installation and debugging

- On-site operation training

- Molding process training

- YFO services

- Preventive maintenance

- Device upgrade