Removal and insertion robot system

Experienced in designing claw hands for various types of inlay pieces, the precise material handle arms and product robot arms ensure stable and reliable gripping.

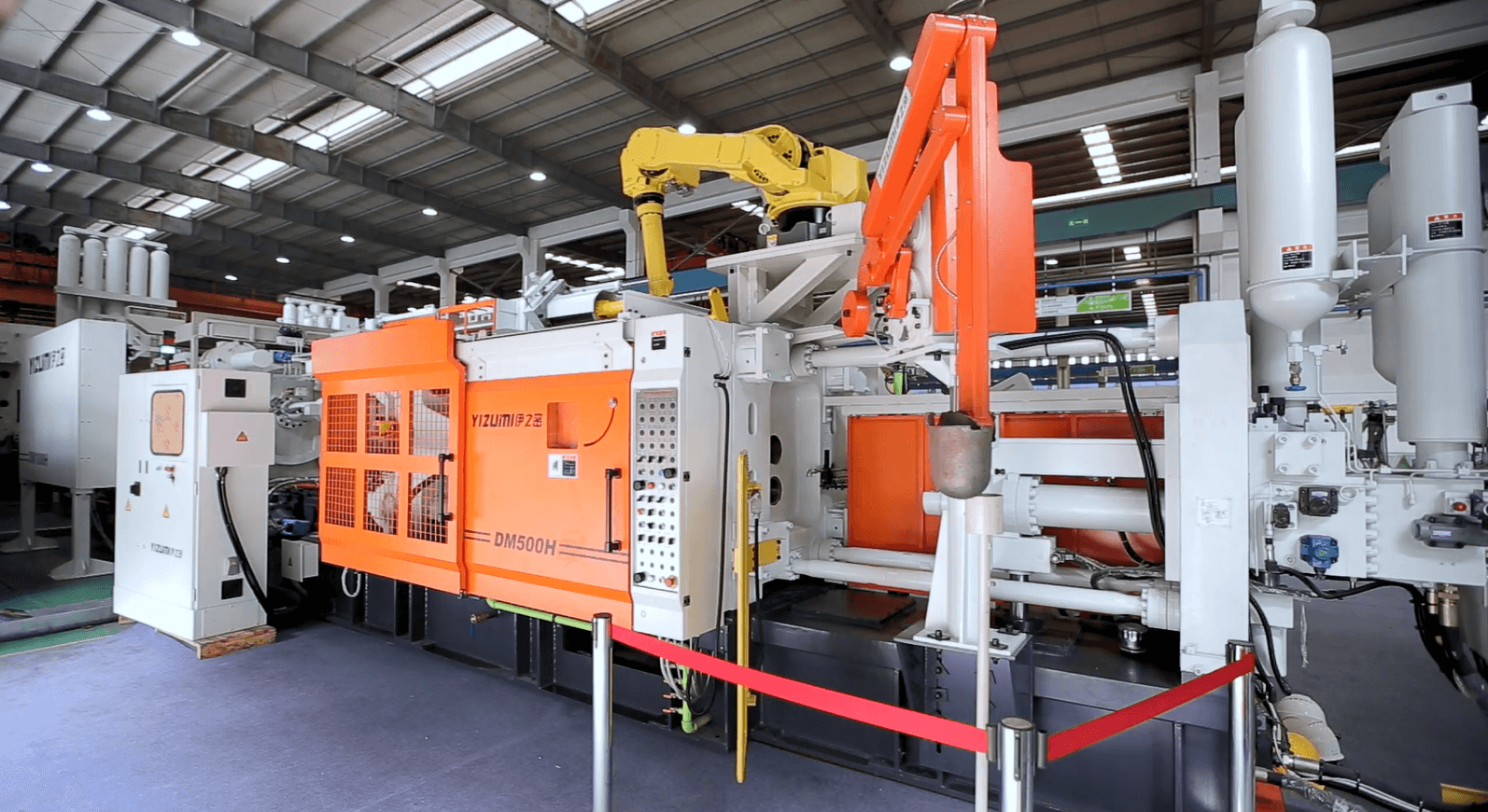

Sprayer robot system

Advanced design concepts, accurate control, manually programmable and adjustable spray time, spray point and spray amount.

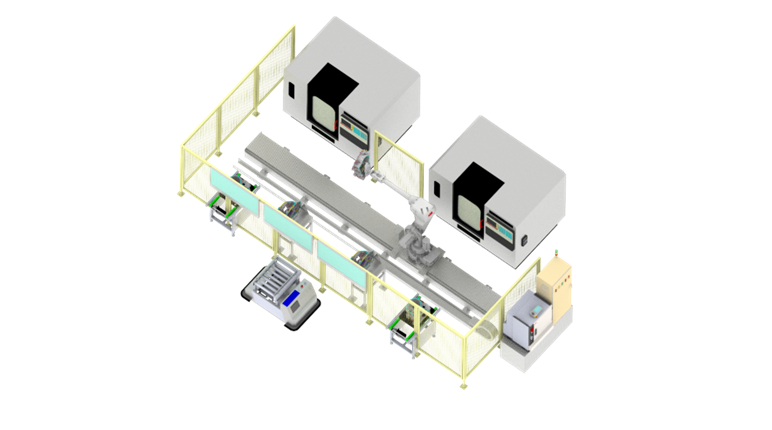

Optional automated peripherals

A variety of peripheral equipment could be integrated into the die casting cell for different products production and customer needs.

Product Video

Industry Application

Relevant Recommendation

Relevant Products

Service Process

01

Process/Mold Analyse and Design

- Raw materials selection

- Product design

- Mold flow analysis

- Mold design suggestion

02

Equipment Selection Suggestions

- Product performance

- Product quality

- Ease of use

- Safety requirements

03

Whole Plant Planning Advice

- Planning of production line

- Arrangements for people, machines, and materials according to process flow

- Peripheral automation

- Smart connection

04

Delivery Solutions

- Professional installation and debugging

- On-site operation training

- Molding process training

05

After Sales Solutions

- YFO services

- Preventive maintenance

- Device upgrade

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.