Reduced wall-thickness for thin-wall packaging: From the thin-wall to the ultra-thin-wall pail

Abstract:

The challenges that developments in the packaging sector place on the injection moulding process. The ever-advancing weight reduction of packaging through reduced wall-thickness is an ongoing topic in the packaging industry, which is constantly increasing the demands on injection moulding machines.

The packaging industry is undergoing a transformative shift, driven by a relentless pursuit of lighter materials and thinner wall constructions. This evolution places considerable demands on injection moulding machines, which must adapt to ensure precision, efficiency, and sustainability. Manufacturers face pressure to produce packaging that not only meets stringent weight reduction goals but also maintains structural integrity and durability. Achieving this requires injection moulding machines capable of precise control over complex molds and rapid cycle times. Moreover, there is a growing emphasis on sustainability, necessitating innovations in materials and processes. Meeting these challenges calls for continuous technological advancements and innovative solutions from industry leaders like YIZUMI.

The trend towards reduced wall-thickness for thin-wall packaging

Packaging industry is continuously evolving, driven by the demand for more efficient, cost-effective, and environmentally friendly solutions. One significant trend is the reduction of wall thickness in thin-wall packaging. This trend not only aims to minimize material usage and weight but also addresses environmental concerns by reducing the overall carbon footprint of packaging. The transition from thin-wall to ultra-thin-wall packaging presents unique challenges for manufacturers, particularly in the injection moulding process. The push for thinner walls places increasing demands on injection moulding machines, requiring advancements in technology and precision.

Save material consumption with thin-wall packaging

Thin-wall packaging offers numerous benefits, primarily the significant reduction in material consumption.

By decreasing the wall thickness, manufacturers can produce more units from the same amount of raw material, leading to substantial cost savings.

Thin-wall packaging also reduces the weight of the final product, which translates to lower transportation costs and decreased energy consumption during distribution.

Additionally, with less plastic used per package, the environmental impact is minimized, aligning with global sustainability goals.

These benefits make thin-wall packaging an attractive option for manufacturers aiming to optimize efficiency while maintaining high standards of quality and performance.

What requirements does a reduced wall thickness for thin-wall packaging place on the injection moulding machine?

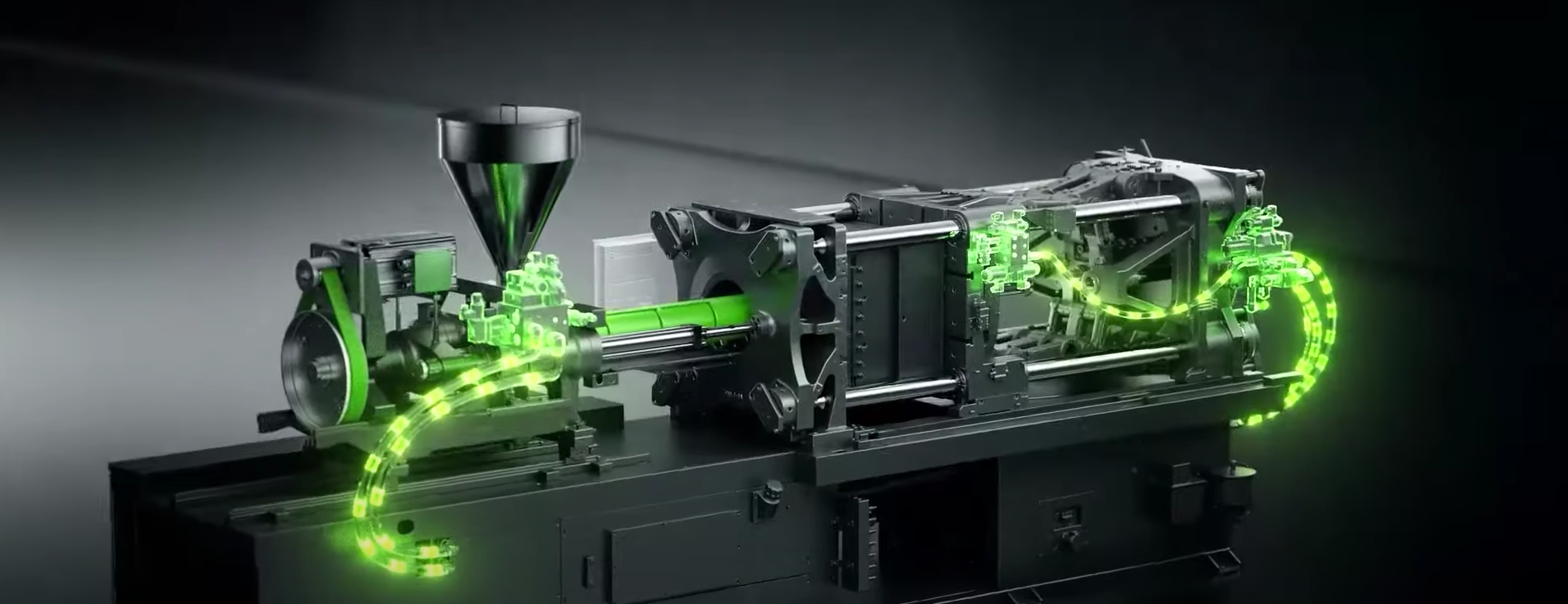

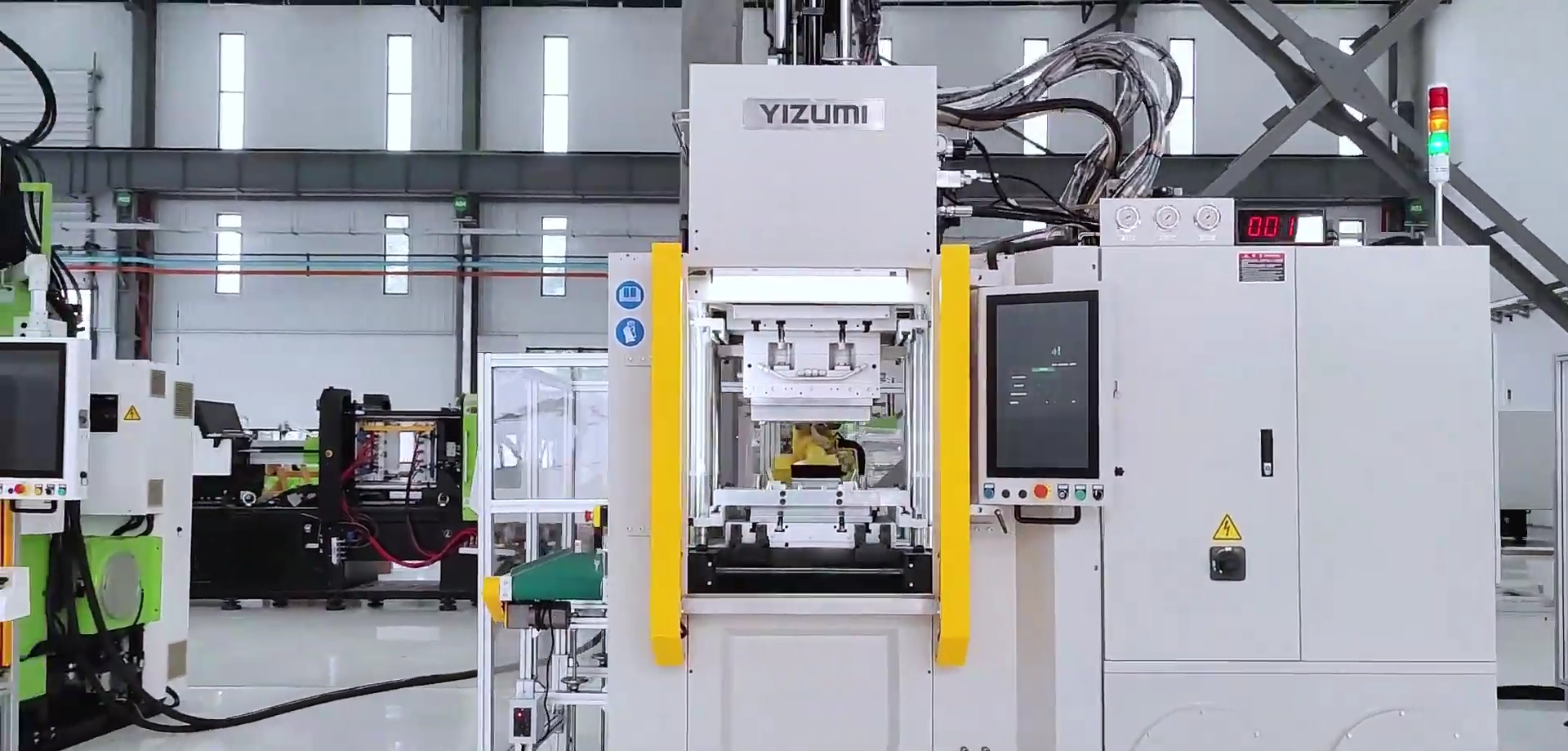

The trend towards thinner wall thickness in thin-wall packaging necessitates injection moulding machines capable of handling the rigorous production demands. This places specific demands on both the injection unit and the clamping unit of the machines. See how YIZUMI's SJII Series Injection moulding Machine for High End Thin-wall Products meets these needs.

High-Rigidity Clamping Unit

Minimizing Platen Deformation - One of the critical aspects of producing thin-wall packaging is ensuring the structural integrity of the mold during the injection process. The SJII series features a high-rigidity clamping unit that minimizes platen deformation. This is essential for maintaining consistent pressure and ensuring the precision of the molded parts. By effectively reducing clamping force in the production of the same product, YIZUMI ensures that the machinery operates efficiently without compromising the quality of the final product.

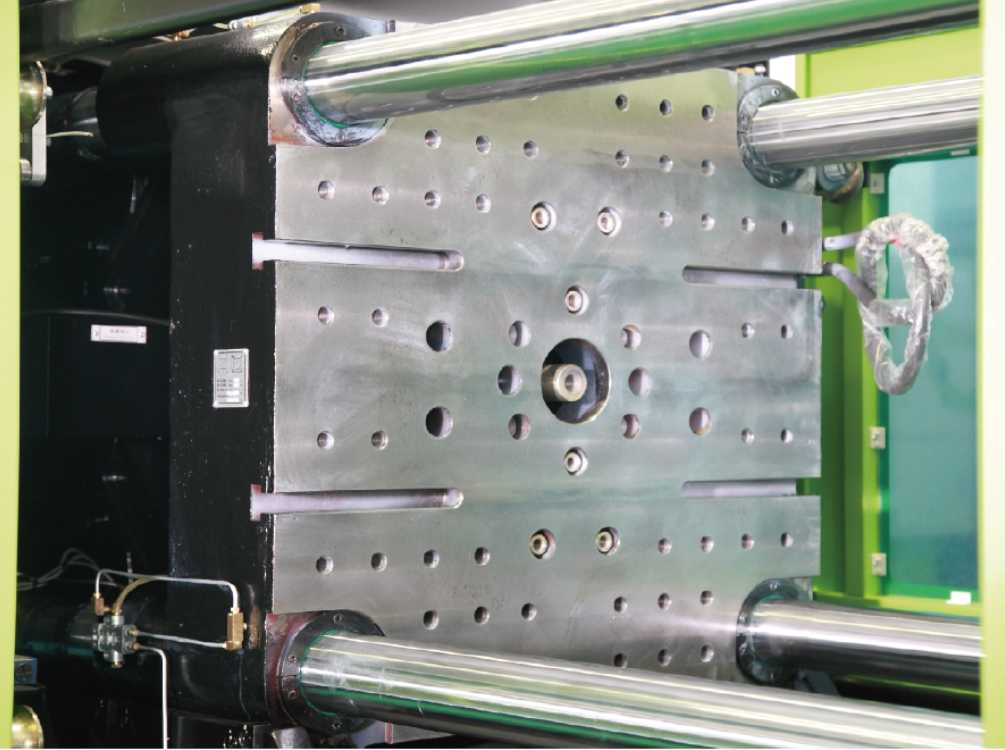

T-Slot and Mold Mounting Hole - The design of the platen in the SJII series incorporates a combination of T-slot and mold mounting holes arranged horizontally, while the vertical direction only features mold mounting holes. This design facilitates the assembly and disassembly of molds, enhancing the overall rigidity of the platen. This structural innovation is crucial for maintaining the accuracy and stability required for thin-wall packaging production.

Extended Guiding Section of Tie Bar Guiding Hole - Stability during the moulding process is paramount. The SJII series addresses this with an extended guiding section of the tie bar guiding hole, which improves the stability of the movable platen. This feature reduces the wear and tear of the mold guide rod during mold opening and closing, ensuring longevity and reliability of the equipment.

Optimized Injection Unit

Improved Injection Stability and Accuracy - The SJII series boasts a further optimized injection unit that enhances injection stability and accuracy. The screw has been upgraded and optimized to ensure quick plasticizing, which is essential for maintaining the flow and consistency of the material during injection. This optimization also improves plasticizing mixing and color mixing effects, minimizing color differences and resolving the difficulty of screw cleaning. To meet market demands, the 160T model machine is equipped with a D26 screw, offering more flexibility in production. The injection speed has been significantly improved, making the SJII series suitable for precision moulding required for high-end thin-wall products.

User-Friendly Design - YIZUMI has also focused on making the SJII series user-friendly to enhance operational efficiency. The double carriage cylinder design helps avoid an overturning moment to the guide rod during injection, improving injection accuracy and reducing wear and tear on the nozzle and mold.

The Drive Concept - Energy-Saving Yet Powerful

Energy efficiency is a significant consideration in modern injection moulding machines, especially when producing thin-wall packaging. The drive concept must balance the need for powerful performance with energy-saving capabilities. Electric and hybrid drive systems are increasingly popular due to their ability to deliver precise control and high efficiency. These systems reduce energy consumption by optimizing the use of power during the injection and clamping phases. Advanced control algorithms and energy recovery systems further enhance efficiency, reducing the overall operational costs and environmental impact of the injection moulding process.

YIZUMI's SJII Series Injection moulding Machines are at the forefront of energy efficiency in manufacturing. Featuring innovative designs in the plasticizing barrel and optimized screw configurations, these machines achieve significant energy savings, reducing barrel heating energy consumption by 5%-8% during static tests. Additionally, the integration of a double carriage cylinder minimizes energy loss by mitigating overturning moments on guide rods during injection, ensuring both precision and efficiency in operations. These energy-saving innovations not only enhance sustainability but also lower operational costs, making the SJII Series an ideal choice for environmentally conscious production environments.

Injection moulding machine for thin-wall packaging with reduced wall thickness: Here's what you should look out for

Precision and Control: The machine must offer precise control over injection speed, pressure, and temperature to ensure consistent quality and uniform wall thickness.

High Dynamics: The injection unit should deliver rapid injection speeds and high pressures to fill the mold cavity completely and uniformly.

Robust Clamping Unit: The clamping unit must provide the necessary force to maintain mold integrity and handle the high pressures and cycle times associated with thin-wall packaging.

Energy Efficiency: Look for machines with advanced drive systems and energy-saving technologies to minimize operational costs and environmental impact.

Durability and Reliability: The machine should be built to withstand the increased wear and tear of high-cycle applications, ensuring reliable performance over extended production runs.

Conclusion

The trend towards reduced wall thickness in thin-wall packaging presents both opportunities and challenges for manufacturers. By embracing this trend, companies can achieve significant material savings, reduce transportation costs, and minimize their environmental impact. However, these benefits come with increased demands on injection moulding machines. Precision, high dynamics, robust clamping units, and energy efficiency are all critical factors to consider when selecting the right equipment for ultra-thin-wall applications.

Manufacturers that invest in advanced injection moulding technology, such as those offered by YIZUMI, will be well-positioned to meet the evolving demands of the packaging industry. By focusing on the latest innovations and maintaining high standards of quality and performance, companies can successfully navigate the challenges of reduced wall thickness and stay ahead in the competitive packaging market.