Medical technology injection molding at the highest level

Abstract:

There are many types of medical products, and the requirements of different products are also different. Yizumi has accumulated rich experience in long-term practice and can provide different solutions based on product requirements and combined with investment planning. Our solutions can cover production planning, injection molding machine and mold selection, product inspection and removal, intelligent production management, etc.

The medical manufacturing industry demands the highest standards of precision, reliability, and efficiency. Injection molding technology plays a pivotal role in producing a wide range of medical products, each with unique requirements and specifications. YIZUMI, a leader in injection molding solutions, has accumulated extensive experience and expertise in this field. There are many types of medical products, and the requirements of different products are also different. YIZUMI has accumulated rich experience in long-term practice and can provide different solutions based on product requirements and combined with investment planning. Our solutions can cover production planning, injection molding machine and mold selection, product inspection and removal, intelligent production management, etc. This article explores the advanced capabilities of YIZUMI's medical injection molding technology, highlighting how it meets the diverse needs of medical manufacturers and ensures the production of high-quality medical devices and components.

The Initial Situation

In the highly demanding field of medical manufacturing, precision, reliability, and adherence to strict standards are paramount. Medical injection molding plays a pivotal role in producing a diverse array of critical products, ranging from syringes and catheters to intricate components used in diagnostic devices and surgical instruments. Each type of medical product comes with specific requirements, necessitating specialized solutions to ensure quality and compliance with stringent regulations.

YIZUMI has established ourselves as a leader in providing advanced medical injection molding solutions, leveraging our extensive experience and innovative approach. We understands the unique challenges of medical technology production, where cleanliness and precision are non-negotiable. Manufacturing typically occurs in clean rooms to prevent contamination of plastic parts. Moreover, the reliability of medical components is critical, as they directly impact patient care and safety. YIZUMI ensures this reliability through meticulous process control, stringent quality assurance measures, and comprehensive documentation throughout production. These practices guarantee that every part meets the highest standards of functionality and performance, crucial in medical emergencies where lives are at stake.

Our commitment to excellence in medical injection molding is evident in its tailored solutions that meet the rigorous demands of the medical manufacturing industry. By prioritizing cleanliness, precision, and reliability, YIZUMI empowers medical device manufacturers to deliver products that uphold the highest levels of quality and compliance with regulatory requirements.

The Request

Medical manufacturers insist on injection molding solutions that not only meet existing industry standards but also elevate them, ensuring they exceed stringent requirements through unmatched precision and unwavering reliability. The primary requests include:

Precision and Accuracy - Medical products must meet exact specifications to ensure safety and effectiveness. Any deviation can lead to serious consequences.

Consistency - It is paramount in medical manufacturing, where the ability to reliably produce identical parts across extensive production runs is crucial for ensuring product quality and reliability.

Material Compatibility - Medical injection molding must be compatible with a variety of biocompatible materials that meet health and safety standards.

Regulatory Compliance - Solutions must comply with international medical standards and regulations, such as ISO 13485 and FDA requirements.

Scalability - The solution should be scalable to accommodate production volume changes without compromising quality.

Intelligent Production Management - Integration of smart technologies for monitoring and managing production processes to ensure efficiency and traceability.

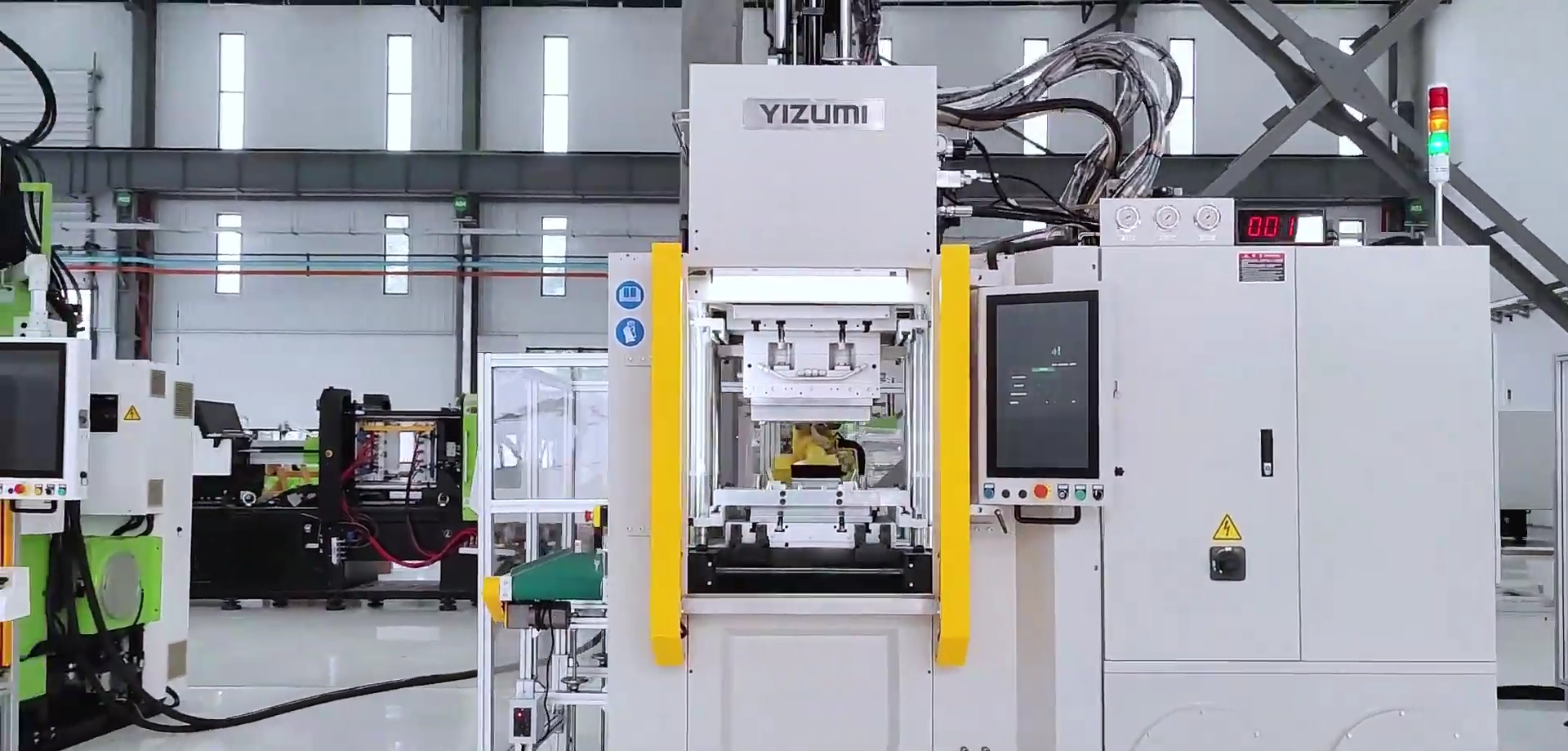

The Machine

To address the intricate and stringent demands of medical injection molding, YIZUMI has pioneered advanced injection molding machines meticulously crafted for the medical sector. A great solution for medical injection molding, YIZUMI's FF-M Series Injection Molding MachineSpecial for Medical Industry, see what this machine can offer you.

Clamping Unit

Stable Tie-Bar Free(TBF) structure

- No contact between the platen and the tie bars, and no lubricating oil on the tie bars, avoid contamination to product;

- Low mechanical friction resistance during mold opening and closing, less energy loss;

- Stable and reliable structure.

Injection pressure closed-loop control. Linear guide rail structure

Injection Unit

High speed injection

Injection speed can reach up to 120-150mm/s for more diversified molding applications so that requirements of commonly used medical products can be met.

High plasticizing efficiency, good plasticizing effect. Unique SDC servo direct control technology

Unique SDC servo direct control technology

- The process algorithm built into the servo driver isindependently developed by YIZUMI;

- Control cycle was reduced from 2-4ms to 0.125ms;

- Injection position, mold opening and closing positionswitching position and control position accuracy aremore accurate.

Intelligent weight control

- Automatic monitoring and real-time dynamic adjustment of molding process parameters;

- Effectively reduce the impact of external factors on the molding process, such as mold temperature, raw material properties, etc., to improve the stability of the process;

- Effectively reduce product weight differences and improve consistency.

YIZUMI's FF-M Series Injection Molding MachineSpecial for Medical Industry excels in meeting the stringent requirements of medical injection molding. Ideal for cleanroom production, it offers a short dry cycle, enhancing productivity and consistency in medical product manufacturing.

The Solution

YIZUMI’s comprehensive approach to medical injection molding solutions covers every aspect of the production process, from initial planning to final product inspection and intelligent production management.

Production Planning

YIZUMI works closely with medical manufacturers to develop detailed production plans that align with their specific needs and goals. This includes understanding the product requirements, production volumes, and timelines. By leveraging their extensive experience, YIZUMI can provide valuable insights and recommendations to optimize the production process.

Injection Molding Machine and Mold Selection

Choosing the right injection molding machine and mold is critical for the success of any medical manufacturing project. YIZUMI’s experts guide manufacturers in selecting the most suitable equipment based on the product specifications, material compatibility, and production requirements. This ensures that the machinery used is capable of delivering the precision and quality needed for medical products.

Product Inspection and Removal

Quality control is a crucial component of medical injection molding. YIZUMI implements rigorous inspection protocols to ensure that each part meets the required specifications. Advanced inspection technologies, such as automated vision systems and in-line quality checks, are used to detect and eliminate defects. Efficient product removal systems are also integrated to ensure smooth and contamination-free handling of finished products.

Intelligent Production Management

YIZUMI’s solutions incorporate intelligent production management systems that enable real-time monitoring and control of the injection molding process. These systems provide valuable data and insights that help manufacturers optimize their operations, improve efficiency, and ensure traceability. Features such as predictive maintenance, process optimization, and automated reporting enhance overall productivity and reduce downtime.

Conclusion

Medical injection molding is a complex and demanding field that requires specialized solutions to meet the high standards of the medical manufacturing industry. YIZUMI has proven ourselve as a leader in this area, offering cutting-edge injection molding machines and comprehensive solutions that cater to the diverse needs of medical product manufacturers.

By combining our extensive experience with innovative technologies, YIZUMI provides solutions that cover all aspects of the production process. From meticulous production planning and precise machine selection to rigorous product inspection and intelligent production management, YIZUMI ensures that manufacturers can produce high-quality medical products efficiently and consistently.

For medical manufacturers looking to achieve excellence in their injection molding processes, YIZUMI offers the expertise and technology necessary to meet and exceed industry standards. The commitment to precision, reliability, and innovation makes YIZUMI the ideal partner for advancing medical injection molding to the highest level. Welcome to our website to learn more about Injection Molding Solutions