How Electric Injection Molding Shortens Cycle Times in the Packaging Industry

Abstract:

Discover how electric injection molding machines reduce cycle times, enhance productivity, and boost efficiency in the packaging industry, even with high clamping forces.

Preface:

In the competitive packaging industry, efficiency is paramount. With growing consumer demand and increasing market pressures, manufacturers are constantly seeking ways to enhance productivity while maintaining high-quality standards. One of the most significant advancements in recent years is the adoption of electric injection molding technology. This technology, particularly through electric injection molding machines, has revolutionized packaging by drastically reducing cycle times. In this article, we'll explore how electric injection is transforming the packaging industry, even with high clamping forces, and how it contributes to increased productivity.

Section 1: Electric Injection Molding with High Clamping Forces:

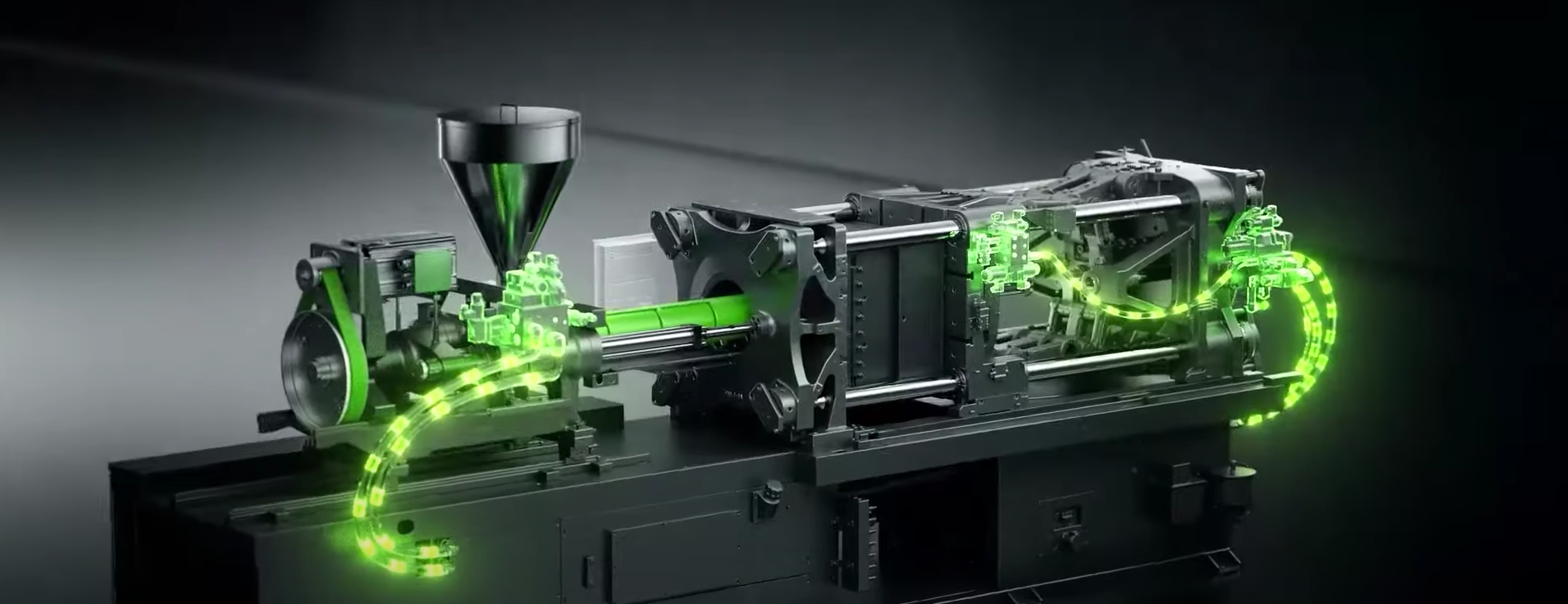

One of the primary challenges in the packaging industry is achieving high clamping forces to ensure the integrity and precision of molded parts. Traditionally, hydraulic systems were used for this purpose, known for their robustness but often slower and less efficient. However, with the advent of electric injection technology, manufacturers can now achieve equal or higher clamping forces with significantly improved efficiency.

Electric injection molding machines utilize servo motors to control the clamping unit, offering precise force control during the molding process. This precision leads to faster mold movements and reduced cycle times, as the machine can quickly and accurately apply the necessary force without the lag associated with hydraulic systems. The ability of electric injection to maintain high clamping forces while operating at higher speeds is a game-changer for the packaging industry, where every second saved translates to increased production output.

Section 2: Contribution to Increased Productivity:

The reduction in cycle times brought about by electric injection technology directly contributes to increased productivity in the packaging industry. Shorter cycle times mean more parts can be produced in a given period, allowing manufacturers to meet higher demand without compromising quality. Additionally, electric injection molding machines offer other productivity-enhancing benefits that further drive efficiency.

One such benefit is the improved energy efficiency of electric injection systems. Unlike hydraulic machines, which consume energy continuously, even when idle, electric injection molding machines only use energy when needed. This not only reduces operating costs but also minimizes the machine's environmental impact, aligning with the growing industry focus on sustainability.

Moreover, electric injection technology allows for faster start-up times and more consistent cycle times. The precision of the servo motors ensures that each cycle is identical, reducing defects and the need for rework. This consistency is particularly crucial in the packaging industry, where uniformity and quality are paramount.

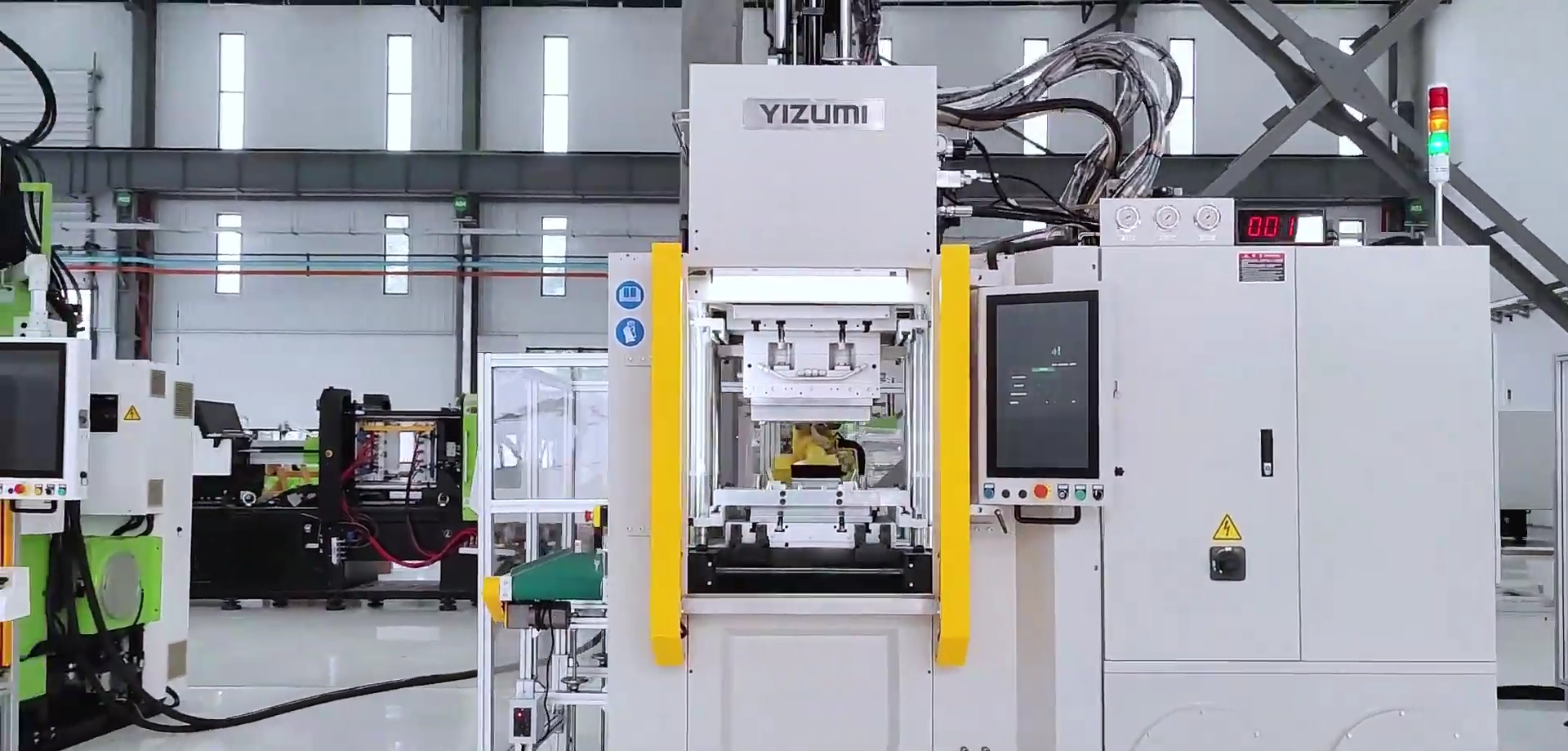

YIZUMI’s FF Series Electric Injection Molding Machine is a prime example of how this technology significantly enhances production efficiency. Featuring a dual-cylinder parallel ejection system, it ensures uniform force application and precise ejection positioning within 0.2mm, improving product accuracy and repeatability. The machine's high stability is supported by TBF technology and a unique "SMART" mold protection feature. With LGS (Linear Guide Support) technology, the injection unit minimizes friction and enhances rigidity, while the built-in hydraulic pump station and closed-loop pressure control deliver consistent performance. The KEBA2000 Controller allows real-time remote operation and flexible integration of additional features, setting a new standard in injection molding by combining automation and precision for optimal efficiency.

Section 3: The Next Leap in Technology:

As electric injection technology continues to evolve, we can expect even greater advancements in the packaging industry. One area of focus is the integration of smart manufacturing technologies, such as the Internet of Things (IoT) and machine learning, with electric injection molding machines. These technologies enable real-time monitoring and predictive maintenance, further optimizing cycle times and reducing downtime.

Another exciting development is the refinement of multi-component molding processes using electric injection technology. This allows for the simultaneous molding of different materials or colors in a single cycle, reducing the need for additional assembly processes and further shortening production times. As these technologies mature, manufacturers will achieve unprecedented levels of efficiency and flexibility in their production processes.

Furthermore, electric injection molding machines are expected to become more adaptable to a wider range of materials and applications. This adaptability will be crucial as packaging materials evolve, with a growing emphasis on biodegradable and recyclable options. Electric injection technology will play a vital role in ensuring that these new materials can be efficiently and reliably molded, keeping pace with the industry's sustainability goals.

Conclusion:

The adoption of electric injection molding technology is revolutionizing the packaging industry by significantly shortening cycle times and boosting overall productivity. Electric injection molding machines are highly valued for their ability to deliver substantial clamping forces with exceptional precision and efficiency, making them indispensable for manufacturers aiming to enhance their production processes. These machines offer faster cycle times compared to traditional hydraulic systems due to their advanced design and precision control, leading to more efficient operations and reduced production costs.

As technology continues to advance, further reductions in cycle times and increased productivity are expected, allowing manufacturers to meet the growing demands of the market with greater ease. Electric injection molding machines are not just a trend but a fundamental shift in manufacturing practices, providing substantial benefits such as lower energy consumption, improved consistency, and reduced maintenance needs.

For packaging manufacturers striving to remain competitive in an increasingly demanding market, adopting electric injection molding technology is no longer a choice but a necessity. Investing in this cutting-edge technology today will position companies to lead the market tomorrow, ensuring they can meet future challenges and capitalize on opportunities with unparalleled efficiency and effectiveness. The future of the packaging industry is undeniably electric, and those who embrace this innovation will be at the forefront of industry advancements and success.