Enhancing Efficiency with Modern Die Casting Machines: A Complete Guide

Abstract:

Explore how modern die casting machines improve efficiency, precision, and cost-effectiveness in manufacturing. Discover advanced technologies, real-world applications, and tips for choosing the right machine.

Preface:

In the fast-paced manufacturing landscape, optimizing efficiency is crucial to staying competitive. Modern die casting machines have become indispensable tools for industries looking to enhance their production processes. These machines offer unparalleled precision, cost-effectiveness, and adaptability, making them ideal for a wide range of applications. This guide delves into the latest advancements in die casting technology and provides insights into choosing the right machine for your specific needs. We’ll also explore real-world examples of successful implementations and discuss future trends in die casting technology.

Introduction:

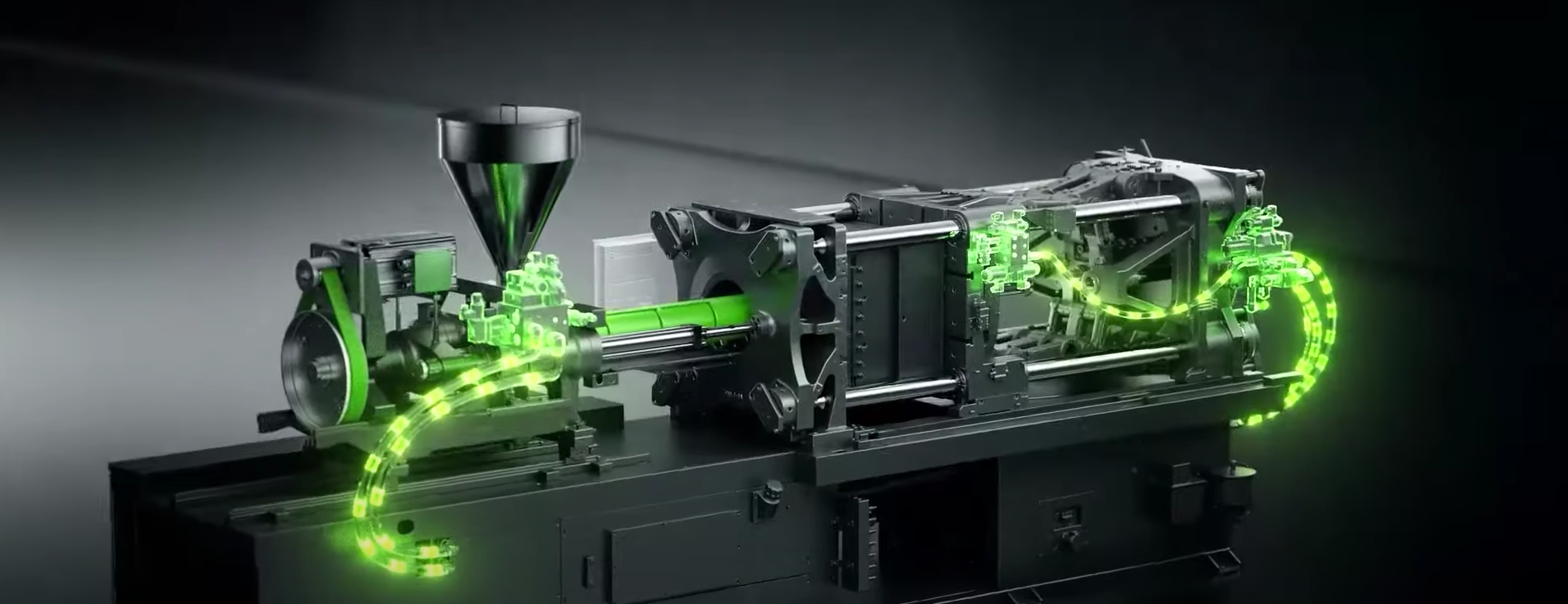

Die casting machines are essential for producing high-quality metal parts with complex geometries. These machines inject molten metal into a mold cavity under high pressure, resulting in components with excellent dimensional accuracy and surface finish. With advancements in technology, modern die casting machines have become more efficient, reliable, and versatile, catering to various industries such as automotive, aerospace, and electronics.

Section 1: Advancements in Die Casting Technology:

The die casting industry has seen significant advancements in recent years, driven by the need for greater efficiency and precision. Modern die casting machines now feature advanced automation, real-time monitoring systems, and energy-efficient designs. One notable innovation is the integration of servo motors, which provide precise control over the injection process, resulting in improved part quality and reduced cycle times.

Section 2: Key Benefits of Modern Die Casting Machines:

Efficiency:

Modern die casting machines are engineered with a focus on maximizing operational efficiency. They feature accelerated cycle times, which significantly shorten the time required to produce each cast part, thereby increasing overall productivity. These machines are designed to consume less energy compared to older models, thanks to innovations such as advanced hydraulic systems and energy-efficient motors. Additionally, they optimize material usage by minimizing scrap and waste, which further reduces operational costs. This combination of faster production, lower energy consumption, and efficient material use enables manufacturers to achieve higher output while keeping expenses in check.

Precision:

In industries like automotive and aerospace, where exacting tolerances are crucial, precision in die casting is paramount. Modern die casting machines are equipped with state-of-the-art features that enhance accuracy and consistency. Real-time process monitoring systems continuously track various parameters, such as temperature and pressure, to ensure that each cast meets stringent quality standards. Automated adjustment mechanisms can promptly correct deviations, maintaining precise dimensions and surface finishes. This high level of precision not only ensures the reliability of critical components but also reduces the likelihood of costly rework or defects, ultimately improving the overall quality of the finished products.

Cost-Effectiveness:

Although the initial investment in modern die casting machines may be substantial, the long-term advantages offer significant cost savings. The machines are designed to reduce material waste through improved process control and efficiency. Energy consumption is also lowered due to advanced technologies that optimize power usage. Furthermore, the enhanced production speed means that more parts can be manufactured in less time, increasing throughput and revenue potential. Over time, these factors combine to offset the initial expenditure, leading to overall cost reductions and a favorable return on investment. The cumulative benefits of reduced waste, lower energy costs, and increased production speed make modern die casting machines a cost-effective choice for manufacturers aiming to enhance their operational efficiency and profitability.

Section 3: Choosing the Right Die Casting Machine:

Selecting the right die casting machine involves considering several factors, including the size of the machine, the materials being cast, and the specific application. For example, larger machines are suitable for producing large automotive parts, while smaller machines are ideal for precision components in electronics.

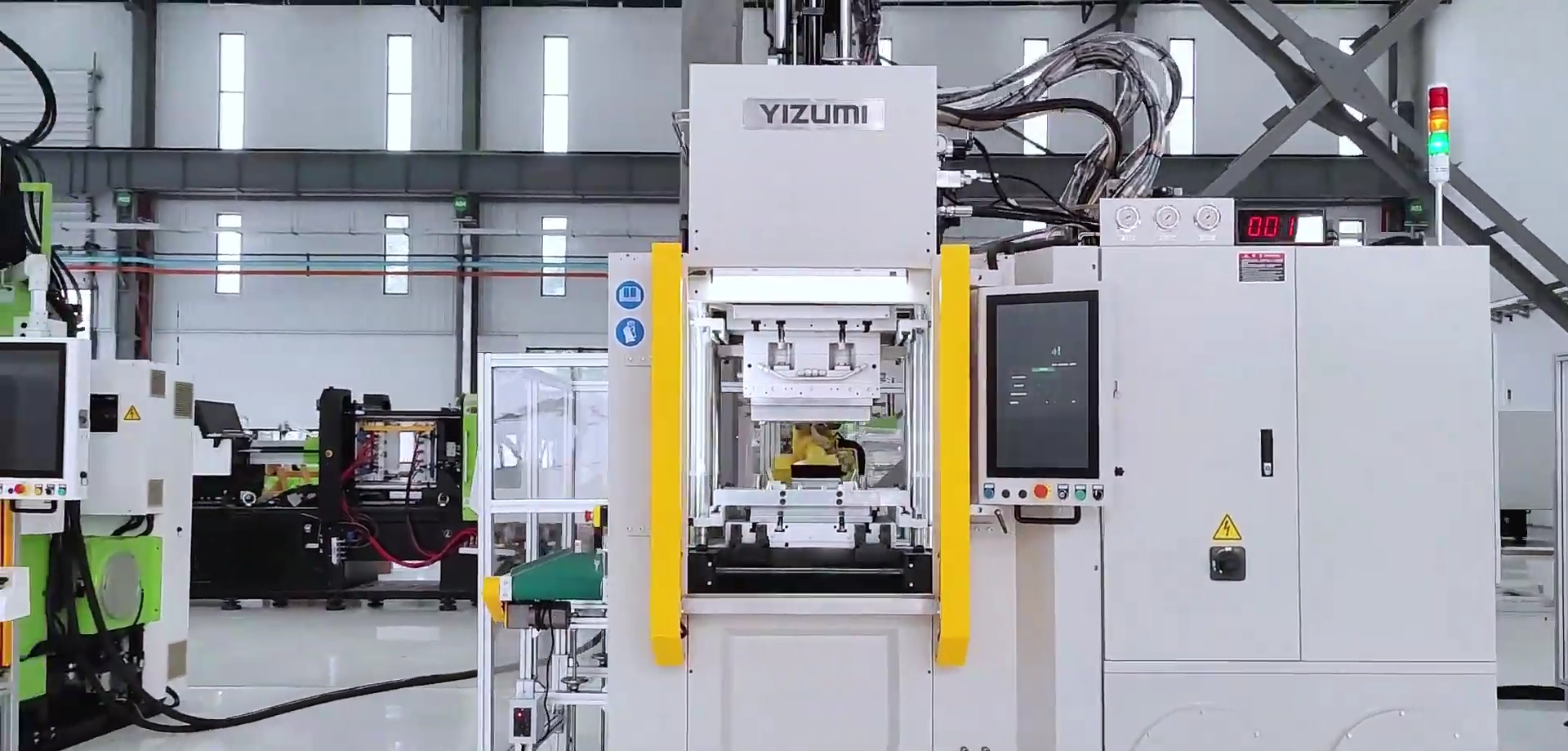

When choosing a die casting machine, it’s essential to evaluate the machine's clamping force, injection speed, and cooling capabilities. The YIZUMI HII-S Series High-end Cold Chamber Die Casting Machine (1000-5000T), with its range of sizes and configurations, provides a versatile solution for manufacturers looking to optimize their production processes.

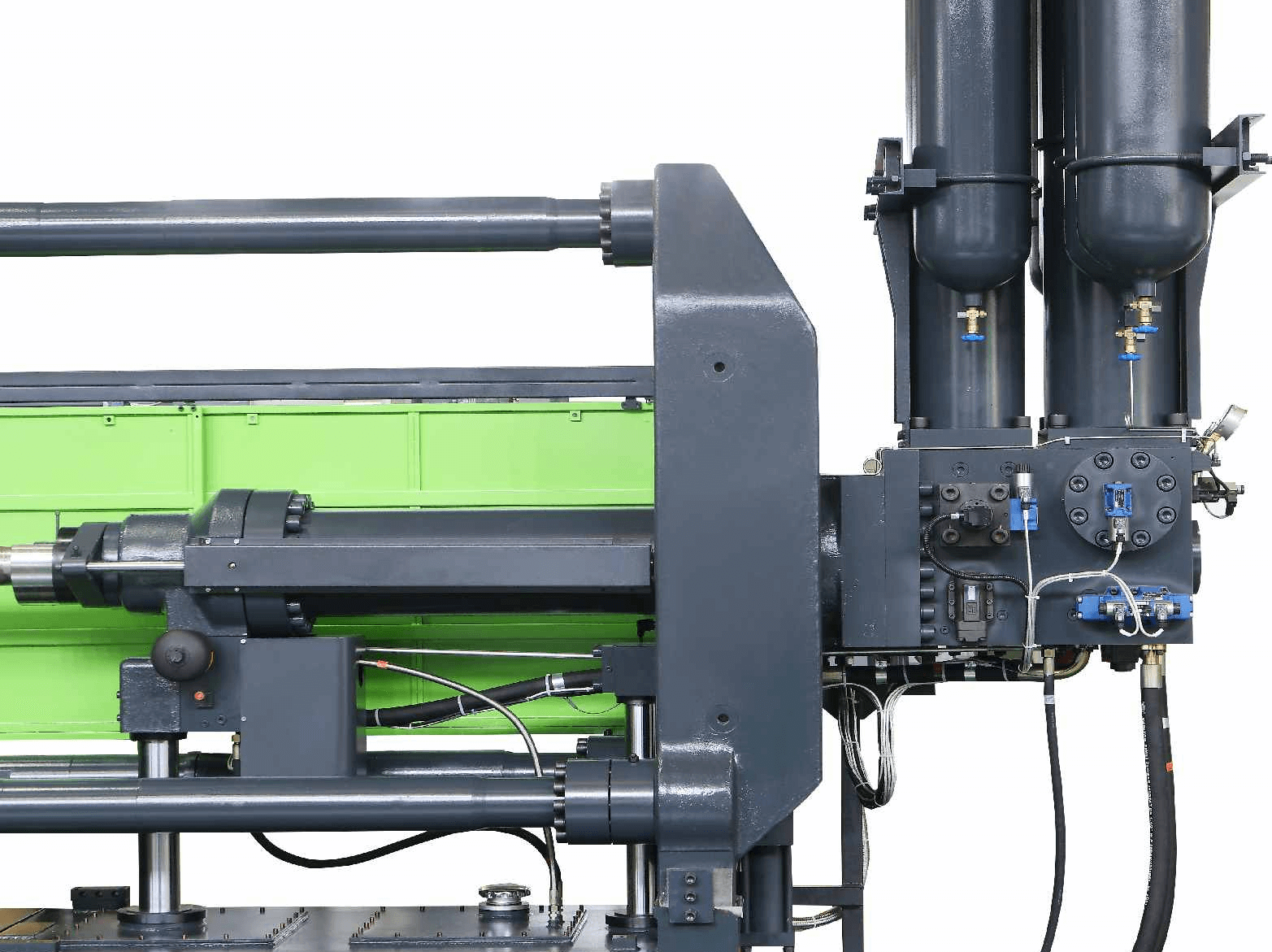

The YIZUMI HII-S Series High-end Cold Chamber Die Casting Machine (1000-5000T) offers a range of cutting-edge features designed to significantly enhance production efficiency. Engineered with a high-performance product line tailored for global markets, this series provides exceptional precision and stability. The advanced Human-Machine Interface (HMI) integrated into the operation panel not only improves user experience but also boosts operational efficiency by ensuring precise control and reduced pressure build-up times. The machine’s top-line acceleration and international-level process repeatability contribute to outstanding casting precision and consistent output.

The HII-S Series incorporates a re-engineered toggle system with increased rigidity, which enhances productivity by improving the machine's overall stability. Its optimized hydraulic drive design reduces cycle times and lowers energy consumption, contributing to cost savings and more sustainable operations. The modular machine design, featuring HPM technology, further stabilizes performance and extends service life.

Additionally, the machine meets the highest safety standards and supports reliable casting production through HMI-supported technology data displays and integrated hydraulic systems. Its user-friendly design, with high-quality international hardware components and excellent maintenance access, ensures ease of operation and minimal downtime. Overall, the YIZUMI HII-S Series delivers superior performance, efficiency, and reliability, making it a top choice for advanced die casting needs.

Section 4: Industry Applications:

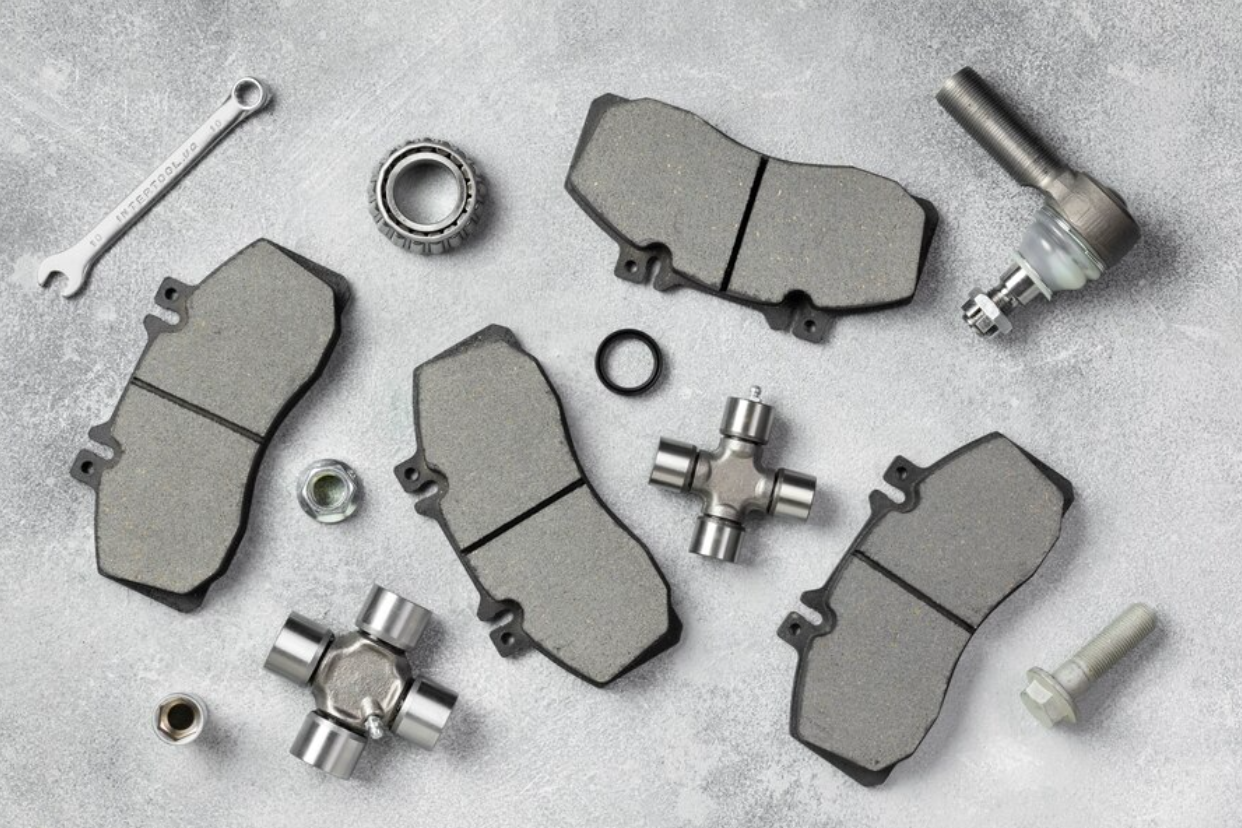

Die casting machines are used across various industries to produce components that require high strength, durability, and precision. In the automotive industry, they are used to manufacture engine blocks, transmission housings, and other critical components. In the electronics sector, die casting machines are essential for producing housings, connectors, and heat sinks. The aerospace industry relies on die casting for components that must withstand extreme conditions while maintaining low weight and high strength.

YIZUMI’s die casting machines have been successfully implemented in these industries, delivering high-quality parts with exceptional efficiency. The versatility of YIZUMI’s machines makes them suitable for a wide range of applications, from large-scale automotive parts to intricate electronic components.

Conclusion:

Modern die casting machines are revolutionizing the manufacturing industry by offering enhanced efficiency, precision, and cost-effectiveness. As technology continues to evolve, these machines will become even more integral to production processes across various industries. The YIZUMI HDC Series Die Casting Machine is a prime example of how advanced technology can drive manufacturing success.

For more information on how YIZUMI’s die casting machines can benefit your business, visit our website and explore our range of innovative solutions designed to meet the needs of modern manufacturers.