Energy consumption of the injection moulding machine down, output up

Abstract:

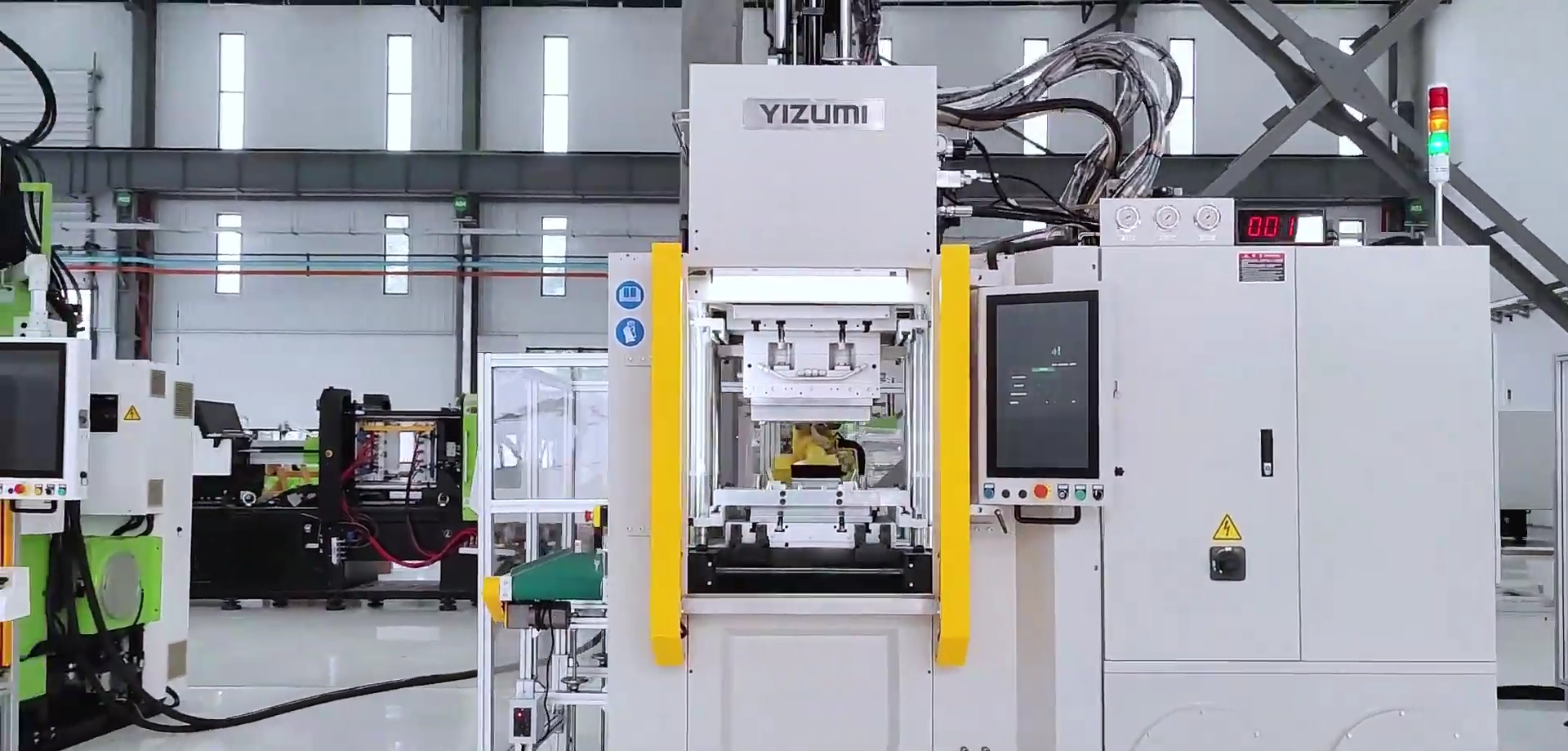

Discover how YIZUMI's P-E Series High-speed Injection moulding Machines drive down energy consumption while boosting output. Equipped with advanced servo motors, efficient transmission, and the European KEBA2000 injection moulding machine controller, these machines offer 30-50% energy savings. Learn how these technical injection systems enhance production efficiency for manufacturers and ensure high-quality outputs with reduced costs.

In today's manufacturing industry, energy efficiency and productivity go hand in hand. The ability to reduce energy consumption while simultaneously increasing production output has become a key factor in maintaining a competitive edge. In the world of injection moulding, advances in technology, such as the injection moulding machine controller and servo-driven systems, have opened new doors for manufacturers looking to optimize both performance and sustainability. This article explores how the latest advancements in technical injection technologies are revolutionizing energy efficiency, with a specific focus on the YIZUMI' P-E Series High-speed Injection moulding Machine, which is designed to drive down energy consumption while boosting output.

Why Reducing Energy Consumption is Critical in Manufacturing

With rising energy costs and the increasing need for sustainability, manufacturers are focusing more than ever on reducing the energy consumption of their operations. Traditional injection moulding machines are energy-intensive, consuming large amounts of power during the moulding process. Reducing this energy consumption without compromising on output is essential for improving overall efficiency and staying competitive. Energy-efficient machines, like YIZUMI's P-E Series, are built with this goal in mind, offering significant energy savings while maintaining or even improving production rates.

Cycle Time Optimization with High-Efficiency Injection moulding Machines

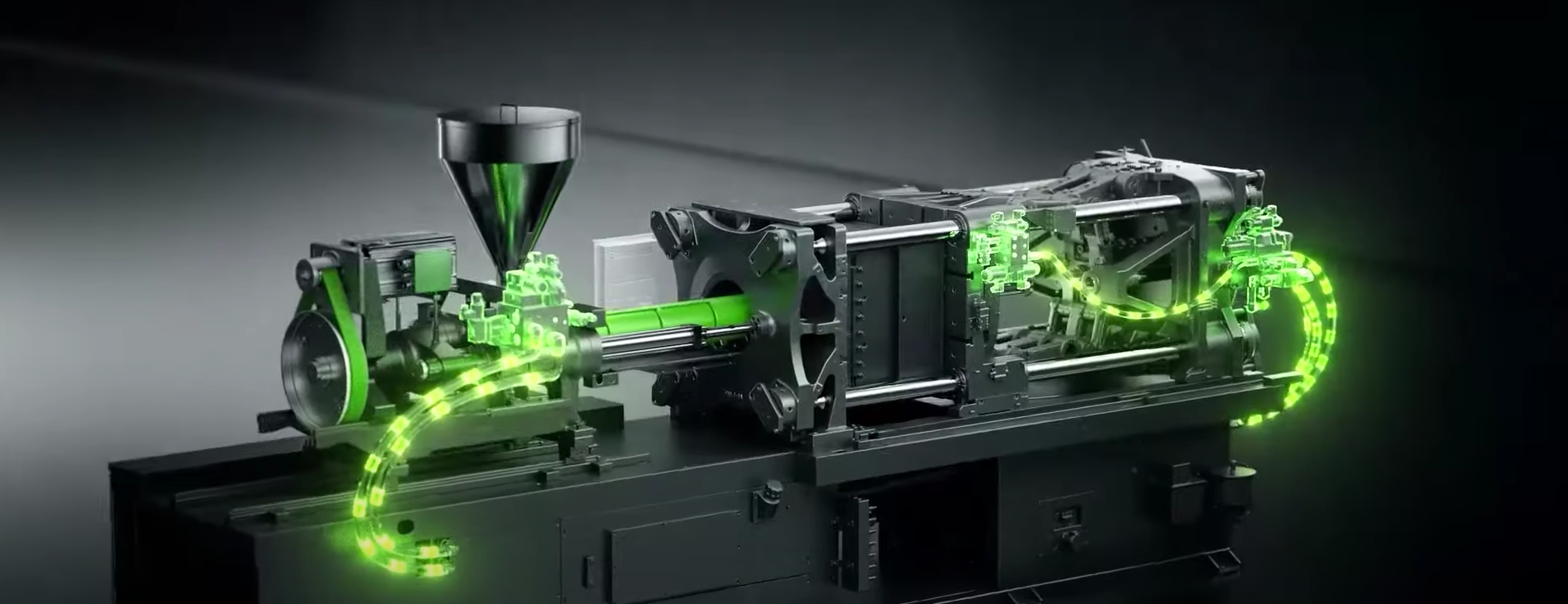

The key to optimizing energy consumption lies in reducing the cycle times of the moulding machine. The P-E Series High-speed Injection moulding Machine is equipped with high-speed servo motors that significantly shorten the dry cycle time to as little as 2-2.6 seconds, depending on the specific production setup. This reduction in cycle time directly translates into higher output while consuming less energy. The P-E Series also integrates advanced technical injection features, including servo direct control (SDC) technology. This independently developed process algorithm by YIZUMI allows for more responsive control, faster feedback, and improved control accuracy. The servo motor controls critical processes, such as injection, plasticizing, and clamping, independently. This ensures not only a reduction in energy consumption but also a higher degree of precision in the production process.

How the KEBA2000 Controller Enhances Energy Efficiency

Central to the P-E Series's ability to save energy is its injection moulding machine controller – the European KEBA2000 controller. This powerful system supports high-performance operations through real-time process monitoring and optimization. With a 1ms scan cycle, the controller ensures that the machine responds quickly to changing conditions, allowing for fine adjustments that help to minimize energy waste. The KEBA2000 controller also includes features like Process Quality Control (PDP) and Statistical Process Control (SPC), which are critical for ensuring that every phase of the moulding process is as efficient as possible. These tools provide detailed data analysis, helping manufacturers identify areas where energy use can be further reduced without impacting quality. Additionally, the centralized, real-time remote operation and control features of the controller align with Industry 4.0 standards, supporting smart factory integration and further driving energy efficiency.

Energy Efficiency without Compromising Output

One of the greatest challenges in manufacturing is finding the right balance between reducing energy consumption and maintaining high output levels. The P-E Series High-speed Injection moulding Machine addresses this by offering both energy-saving features and high-speed production capabilities. The servo motor's direct control over critical machine functions ensures precision, speed, and stability. Furthermore, the machine's unique servo-driven hydraulic system offers flexibility across various moulding processes, making it suitable for a wide range of applications, including automotive parts and packaging. The moulding machine is equipped with tie-bar-free (TBF) technology, ensuring a cleaner mould area and reducing the risk of product contamination, a vital feature for industries with strict hygiene standards, such as food packaging. This feature also contributes to easier maintenance, which further improves uptime and overall productivity. By incorporating these technologies, manufacturers can benefit from shorter cycle times and more precise control over the moulding process, ultimately increasing their production rates while using less energy.

The Role of Servo Motors in Energy Savings

Servo motor technology plays a critical role in improving the efficiency of modern injection moulding machines. In the P-E Series, the servo motors work in tandem with the machine's hydraulic pump station to provide precise control over the moulding process, reducing energy use during idle periods and lowering power consumption during production cycles. This technology delivers an impressive 30-50% energy savings compared to traditional machines, depending on the operating conditions. Moreover, the servo motors allow for real-time adjustments to the speed, pressure, and position of the machine's components, further optimizing energy usage. This kind of technical injection not only reduces energy consumption but also improves the overall quality and consistency of the products being manufactured, which is essential for industries like automotive and packaging.

Boosting Output with Smart moulding Technology

Reducing energy consumption is just one part of the equation. Manufacturers also need machines that can boost production output without compromising on quality. The P-E Series High-speed Injection moulding Machine achieves this through its high-speed operation and unique features like the "SMART" mould protection system, which prevents machine errors and ensures smooth production runs. With clamping forces ranging from 200 to 350 tons, the P-E Series provides the flexibility needed to handle various moulds and products while maintaining high efficiency. This makes it an ideal solution for manufacturers in sectors like packaging, where high output and low energy consumption are crucial for maintaining profitability.

Conclusion: Energy Efficiency Drives Future Success

In today's competitive manufacturing landscape, reducing energy consumption while increasing output is essential for long-term success. The YIZUMI P-E Series High-speed Injection moulding Machine offers manufacturers an advanced solution that combines energy-saving technologies with high-speed production capabilities. With its state-of-the-art injection moulding machine controller, servo motor technology, and smart design features, the P-E Series helps manufacturers optimize their production processes and achieve significant energy savings.

For manufacturers looking to reduce costs, improve efficiency, and meet sustainability goals, the P-E Series High-speed Injection moulding Machine represents the perfect balance between performance and energy conservation. Visit our website to learn more about how YIZUMI's innovative technologies can help your business thrive.