Advanced Injection Molding for Medical Technology Excellence

Abstract:

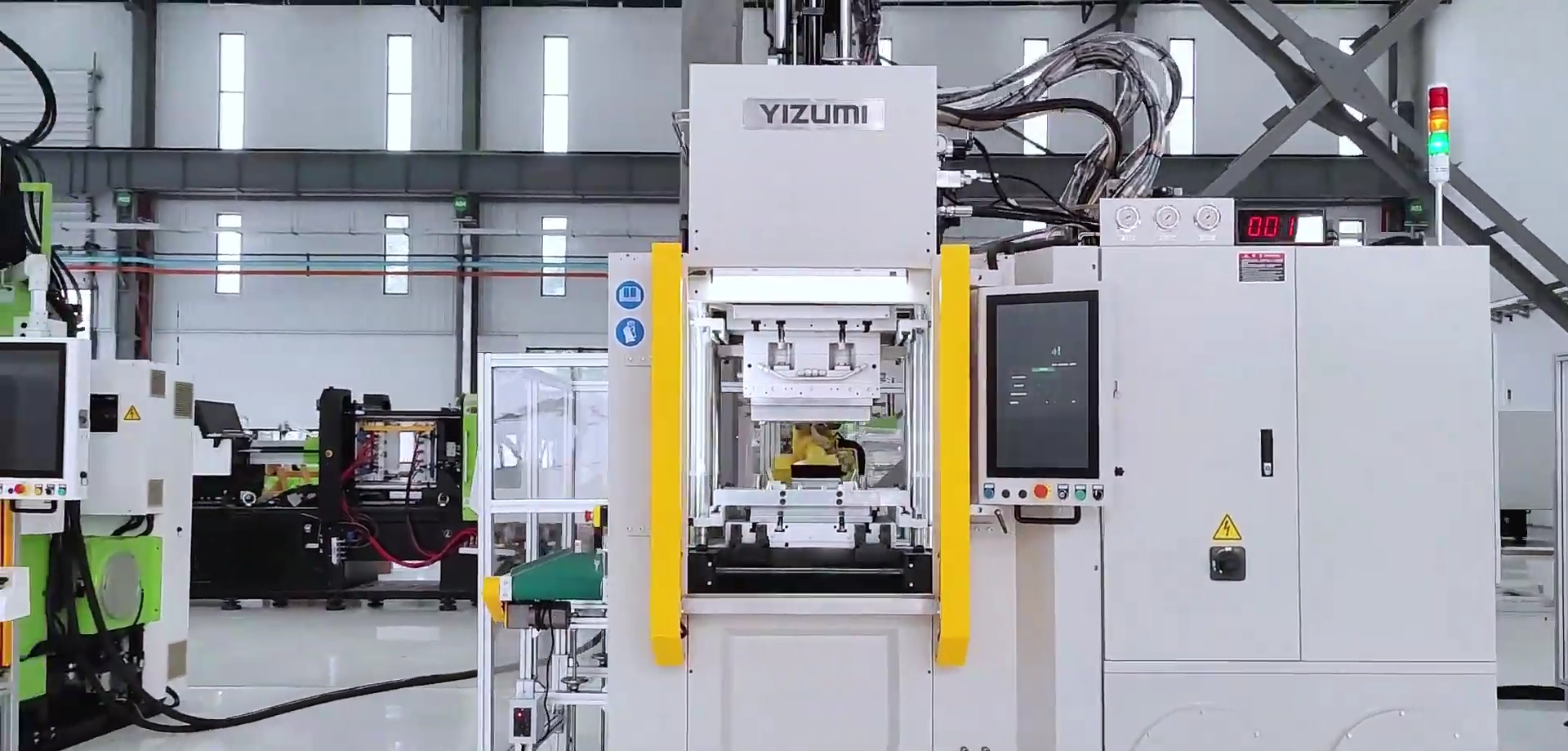

When manufacturing medical technology products in the clean room, maximum precision is essential for every cycle. Combining precision, process reliability and cost-effectiveness with all-electric injection molding machines from YIZUMI.

The medical industry demands the highest standards when it comes to precision, safety, and cleanliness. To meet these stringent requirements, manufacturers rely on advanced electric molding machines tailored for medical applications. Injection molding is a key process in producing a wide range of medical devices, from blood tube filters to disposable syringes. With the rise of all electric molding machines, the industry is witnessing new possibilities for precision and efficiency. In this article, we explore how the latest innovations in molding machines are transforming medical technology manufacturing and why YIZUMI's FF-M Series Injection Molding Machine Special for Medical Industry stands out in this highly specialized field.

Why Precision is Paramount in Medical Technology Injection Molding

Medical devices must meet rigorous quality standards to ensure patient safety. The precision offered by electric molding machines allows manufacturers to maintain tight tolerances, reduce waste, and ensure consistent quality across large production runs. In the medical industry, even slight variations in product dimensions or material consistency can lead to compliance issues or, worse, unsafe products. YIZUMI's FF-M Series Injection Molding Machine is specially designed to meet the needs of medical device manufacturers. Its high-speed injection capabilities and stable Tie-Bar Free structure ensure that medical components are produced with the highest degree of precision and cleanliness, avoiding contamination.

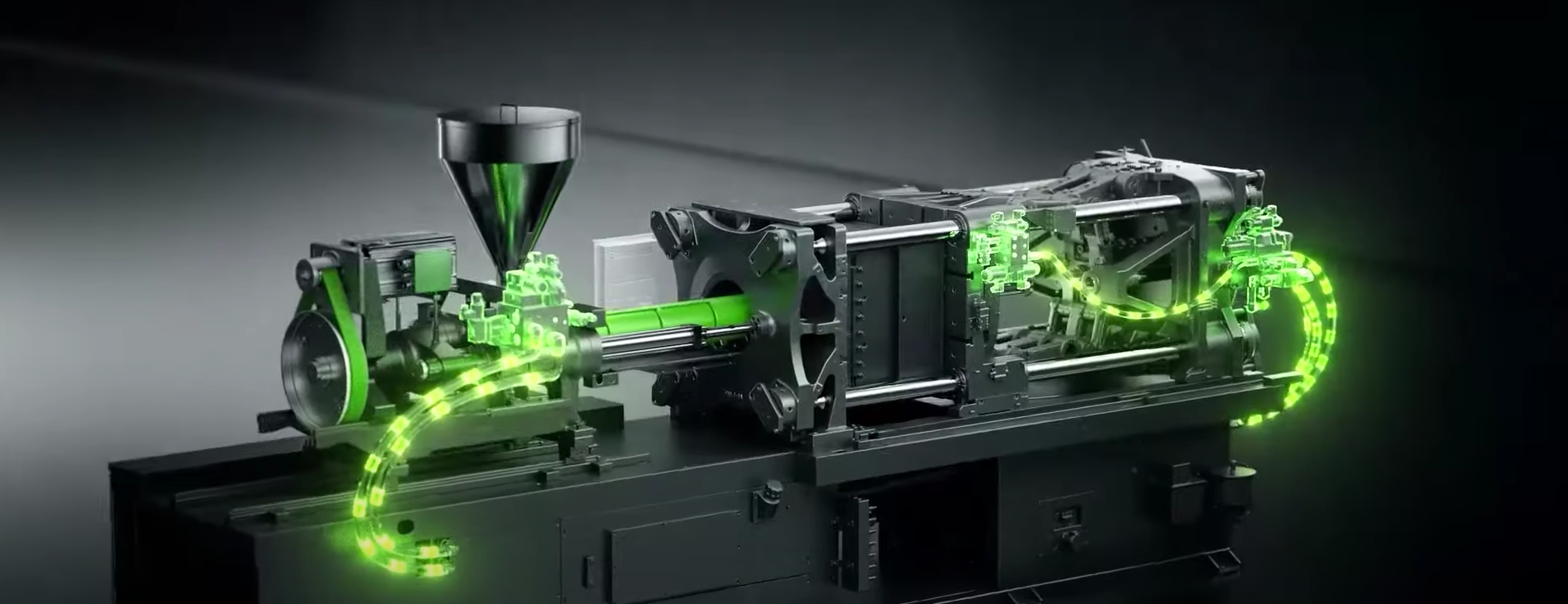

YIZUMI's All Electric Molding Machines for the Medical Industry

YIZUMI's focus on the medical industry has led to the development of all electric molding machines like the FF-M Series, which offers several advantages over traditional hydraulic systems. These machines not only provide higher precision and control, but they are also cleaner, more energy-efficient, and reduce the risk of product contamination. The FF-M Series uses a stable Tie-Bar Free (TBF) structure, which ensures that there is no contact between the platen and tie bars, eliminating the need for lubricating oil. This feature is crucial in the production of medical devices, as it reduces the risk of contamination. Additionally, the low mechanical friction resistance during mold opening and closing results in less energy loss and ensures a smooth, consistent operation.

Advantages of High-Speed Injection in Medical Molding

One of the standout features of YIZUMI's FF-M Series is its high-speed injection capability, which can reach up to 120-150mm/s. This feature is critical for producing commonly used medical products, such as blood tube filters and syringe caps, where speed and precision are paramount.

High-speed injection, combined with the machine's unique SDC servo direct control technology, allows manufacturers to achieve high plasticizing efficiency and good plasticizing effects. This ensures that the medical-grade plastics are molded to exact specifications, minimizing material waste and improving production efficiency. The SDC servo direct control process algorithm, developed independently by YIZUMI, enables real-time adjustments during the injection process, further enhancing the accuracy and stability of the machine.

Intelligent Weight Control for Consistent Production

In the medical industry, consistency is not just desirable—it's mandatory. Variations in product weight or dimensions can lead to non-compliance with regulatory standards. To address this, the FF-M Series includes intelligent weight control. This system automatically monitors and adjusts molding parameters in real-time, ensuring consistent product weight and reducing the impact of external factors like mold temperature or raw material properties. This feature is especially valuable for medical device manufacturers, where even small discrepancies in product weight or dimensions can compromise the safety and effectiveness of the device. With intelligent weight control, manufacturers can ensure that every product meets the required standards, reducing the likelihood of product defects and recalls.

The Role of Electric Molding Machines in Reducing Contamination

One of the key benefits of using all electric molding machines in the medical industry is their ability to operate without the need for hydraulic fluids, which can be a source of contamination. The FF-M Series leverages electric servo motors to control the injection process, eliminating the need for oil-based systems that are commonly found in hydraulic machines. This makes the FF-M Series ideal for the production of sensitive medical components, such as syringe caps and blood tube filters. With its stable Tie-Bar Free structure and no need for lubricating oil, the machine ensures that the production environment remains clean and free of potential contaminants, which is essential for meeting the strict hygiene requirements of the medical industry.

How YIZUMI's FF-M Series Injection Molding Machine Supports Industry 4.0

As the manufacturing industry continues to evolve, the adoption of Industry 4.0 principles is becoming more widespread. YIZUMI's FF-M Series Injection Molding Machine is designed with this in mind, offering advanced features like real-time data monitoring, remote diagnostics, and integration with centralized control systems. The machine's European KEBA2000 controller plays a pivotal role in this, offering a user-friendly interface and a wide range of data management tools. The system supports up to 16 levels of user access, ensuring that sensitive data remains secure while still providing manufacturers with the insights they need to optimize their operations. By integrating electric molding machines like the FF-M Series into their production lines, manufacturers can not only improve precision and efficiency but also gain greater control over their operations. The ability to monitor and adjust processes in real-time enables manufacturers to respond quickly to any issues that arise, minimizing downtime and ensuring that production runs smoothly.

Conclusion: Pushing the Boundaries of Medical Injection Molding

In the medical industry, the stakes are high, and there is no room for error. Manufacturers need molding machines that offer not only precision and consistency but also the cleanliness and control required for producing medical-grade products. YIZUMI's FF-M Series Injection Molding Machine Special for Medical Industry meets these demands with its innovative design, advanced servo-driven technology, and intelligent weight control features. By adopting all electric molding machines, medical manufacturers can ensure that their products meet the strictest standards for quality and hygiene while also benefiting from increased efficiency and reduced contamination risks. For companies looking to push the boundaries of what's possible in medical injection molding, YIZUMI's FF-M Series offers the perfect solution. Visit our website to learn more about how YIZUMI can support your medical manufacturing needs.