Kaisu: Lead Traditional Industry Upgrade with Intelligence

Suzhou Kaisu Plastics Co., Ltd. (Kaisu) was founded in May of 2018. It primarily engages in the manufacturing and selling of plastic products, including electronics, automotive connectors, communication device accessories, as well as the making, processing and selling of molds. In addition, it has established a long-term and cordial partnerships with Danfoss, Foxconn, Pegatron, Arris, Canature and Recodeal, etc.

Because of the rapid development of technology, digitalization has now become a significant and necessary means of brand development, as well as playing an important role in the manufacturing industry. Kaisu joins hands with YIZUMI to actively promote its digital construction and seize the opportunity of digital era based on digital factory solutions.

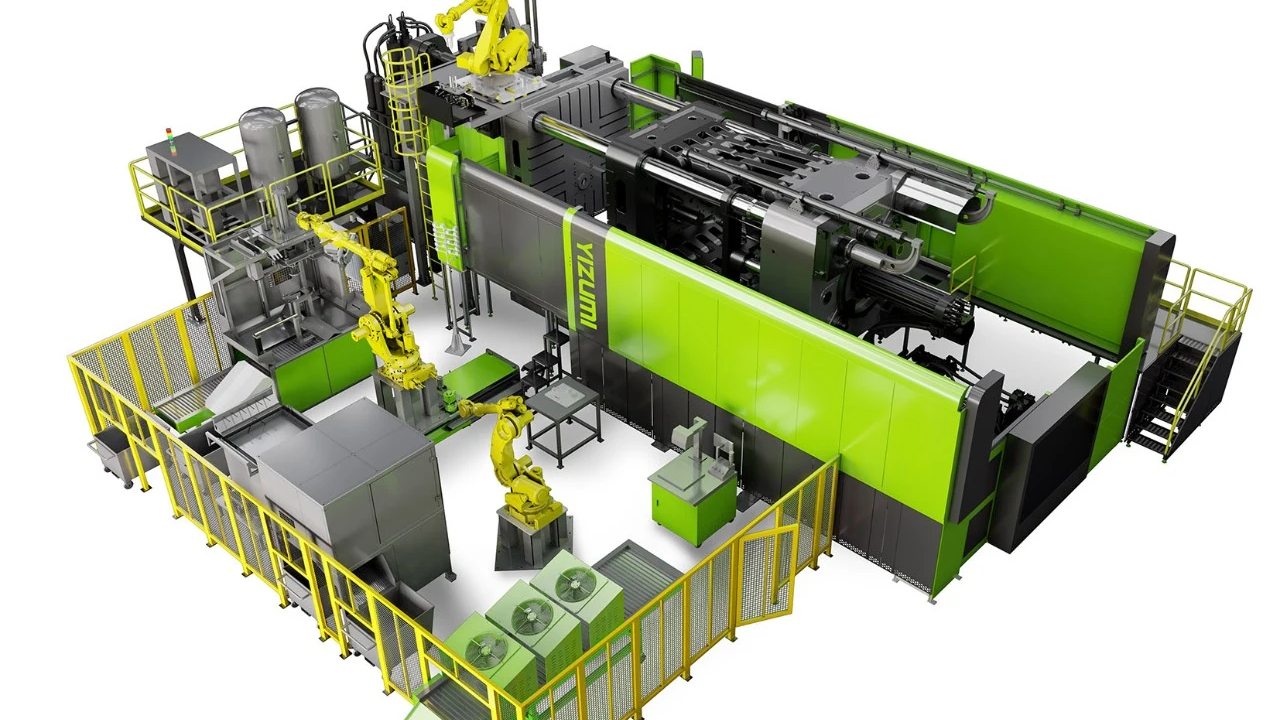

The separation of human and machine aids in the achievement of visual management in production

As soon as you enter Kaisu's injection molding workshop, you'll notice rows of YIZUMI injection molding machines running smoothly, and robots instead of busy staff taking out the molded plastic parts.

The production lines separate injection molding machines from stations of operation, inspection and logistics with conveyors. Robots not only avoid the drawbacks of manual picking and placing parts, but also improve production efficiency, ensure employee safety, and achieve visual management in production.

Furthermore, the continuous operation of the injection molding machine with a regular and efficient speed contributes to higher product quality, as well as a higher qualification rate and a lower scrap rate, which can significantly reduce costs and improve production efficiency.

Mr. Zhang Zhengang, General Manager of Kaisu, said, "'One man, one machine' was the operating mode in our early injection molding workshop. But now, we have separated human work from machine work, creating a clear workshop and giving operators a cool, comfortable workspace, hence reducing staff turnover."

In recent years, Kaisu has been committed to "becoming a trustworthy high-quality injection molding supplier for customers", and has consistently upgraded its products based on customer needs. It was ISO9001 and IATF16949 quality management system certified, and takes the lead in the industry with strict quality control and management systems, as well as clear market insights.

In July 2021, Kaisu expanded its mold making workshop and gradually introduced over 30 YIZUMI A5 series and electric injection molding machines, as well as precision processing equipment such as CNC engraving and milling machines, electrical discharge machining (EDM), milling machines, and grinders, etc. Kaisu's output of plastic molds exceeds 15 sets per month, providing strong support for its business ambition.

A5S Series Injection Molding Machine

Technological innovation brings strong momentum to enterprises

Kaisu is a growing company focusing on innovation. Mr. Zhang Zhengang stressed, "Innovation is No.1 productive force. So we must focus on technological development and innovation to drive our constant high-quality development and give new momentum to the industry."

Kaisu is a customer-centered company. It has a technical team with over 20 years of mold manufacturing experience, as well as strong capabilities in the design, development, production, injection molding, and post-processing of plastic molds, etc. It is committed to creating greater value for customers in the field of mold manufacturing, such as plastic parts for Netcom routers, automobile, smart-home devices, electrical tools, power and chargers, and so on.

It also has a strong marketing and service team that can provide customers with comprehensive technical and maintenance services including pre-project technical support, product manufacturing process, and technical solutions.

Various plastic parts from Kaisu

Mr. Zhang Zhengang stated, "Dimensional accuracy of plastic parts is one of the key indicators, and different plastic parts require different accuracy. We must focus our efforts on mold design to produce high-precision plastic parts. Simultaneously, high-end servo injection molding machines are a key element of precision injection molding."

"YIZUMI has always pursued technological innovation, and achieved important advances in environmental protection, energy conservation, efficiency, economy, and ease of use." Mr. Zhang Zhengang underlined, "Over the several years of collaboration, YIZUMI has provided significant assistance in lowering costs and operating difficulty, as well as improving the product's percentage of pass, and others."

Digital transformation is vital to the enterprise's success

Kaisu is increasingly investing in introducing more talents to innovate its technology. On the one hand, seize the opportunity of intelligent transformation in manufacturing to upgrade its equipment and products. On the other hand, adopt key technologies, namely networking integration, online monitoring, and big data to build a digital and networked service system driven by the Yi MES as the core.

In March 2023, Kaisu began using the YIZUMI Manufactory Execution System (Yi MES). This system can intelligently monitor the status of equipment and automatically collect data, helping Kaisu build a production process execution system, and achieve multiple functions like real-time tracking of production status, abnormal production warning, and full traceability.

Yi MES automatically collects work orders, systematizes and visualizes the production, and monitors process progress in real-time, effectively managing production and improving production efficiency. In terms of monitoring equipment data, interconnected manufacturing devices collect data in real time to Yi MES, allowing management to monitor various equipment and production data dynamically and directly. Moreover, achieving transparent production information, breaking down isolated islands of information, and handling abnormal production on time can help Kaisu effectively reduce losses and anomalies, lower production costs, and raise the on-time delivery rate.

Kaisu builds a real-time interactive information system for production, allowing managers to better allocate tasks and employees to work more productively and collaboratively. It has now made impressive strides in lowering production costs and increasing production efficiency.

Strategy implementation is tougher than strategy formulation. "Our five-year plan is to focus on developing differentiation, particularly unique product functions, to form our core competitiveness and constantly evolve towards more refined segments. And now we need to breakthrough and persevere with clear goals." added Mr. Zhang Zhengang.