AURORA: The way to digitalization and intelligent manufacturing

Aurora Precision Plastic Co., LTD. (AURORA) was established in 2006 in Dongguan, Guangdong, China. Aurora specializes in mold design and manufacturing, as well as precision injection molding. In addition, it primarily engages in mold making, injection molding, and post-processing of plastic accessories such as consumer electronics and medical products.

Based on the strong technical strength, Aurora continually brings new products with great functions and excellent experience to the market every year. After years of development, it has established long-term partnerships with renowned companies like Anker, Haman, Marshall, B&O, Usmile, Hanwang Technology, China Tobacco, etc., and successfully exported its products to global markets, where they are well received.

Aurora Precision Plastic Co., LTD.

Being realistic and innovative to enhance AURORA's core competitiveness

Many people get impressed when they walk into AURORA by its artistic office design. It is a multi-functional and creative space with simple colors and rich art elements, making it a bright and relaxed office.

The display area (as below) in AURORA's office building showcases its independently developed Bluetooth headsets, audio products, and various qualification and patent certificates from previous years, recording its development footprints and inspiring all its employees.

All of these are tightly tied to the efforts and insight of Aurora's general manager, Mr. Zhang Wei, a businessman who has a good taste of art. He believes that strengthening aesthetic sensibility while fostering innovation and creativity result in good products. Therefore, he works hard to achieve this goal.

After 17 years of technical and management experience, Aurora has created considerable advantages in the design, development, and manufacture of high-precision dual-component molds and the application of dual-component precision injection molding and material. Especially, the independently developed one-piece dual component injection mold with alternate core structures of two-color screw and bearing solves several technical difficulties in the field of dual-component molds.

Most managements are keen to be invincible in a changing market. To this, Mr. Zhang Wei said: "The only thing that never changes is that everything changes, and changes drive innovations and advances to help companies lead in the market."

The cool appearance brings users a pleasant experience

AURORA applies the luxury minimalist design style to its products. Thanks to the appearance design and exquisite craftsmanship, products have smooth contours. Mini size makes AURORA products ideal for taking out.

For consumer electronics, having a cool appearance can lead to higher purchase intention. Therefore, the molding of product appearance is crucial. Mr. Zhang Wei introduced: "Bluetooth headset components are tiny and have strict assembly requirements. And the product's surface should be fine and have a smooth texture, thus necessitating a machine with high precision and stability."

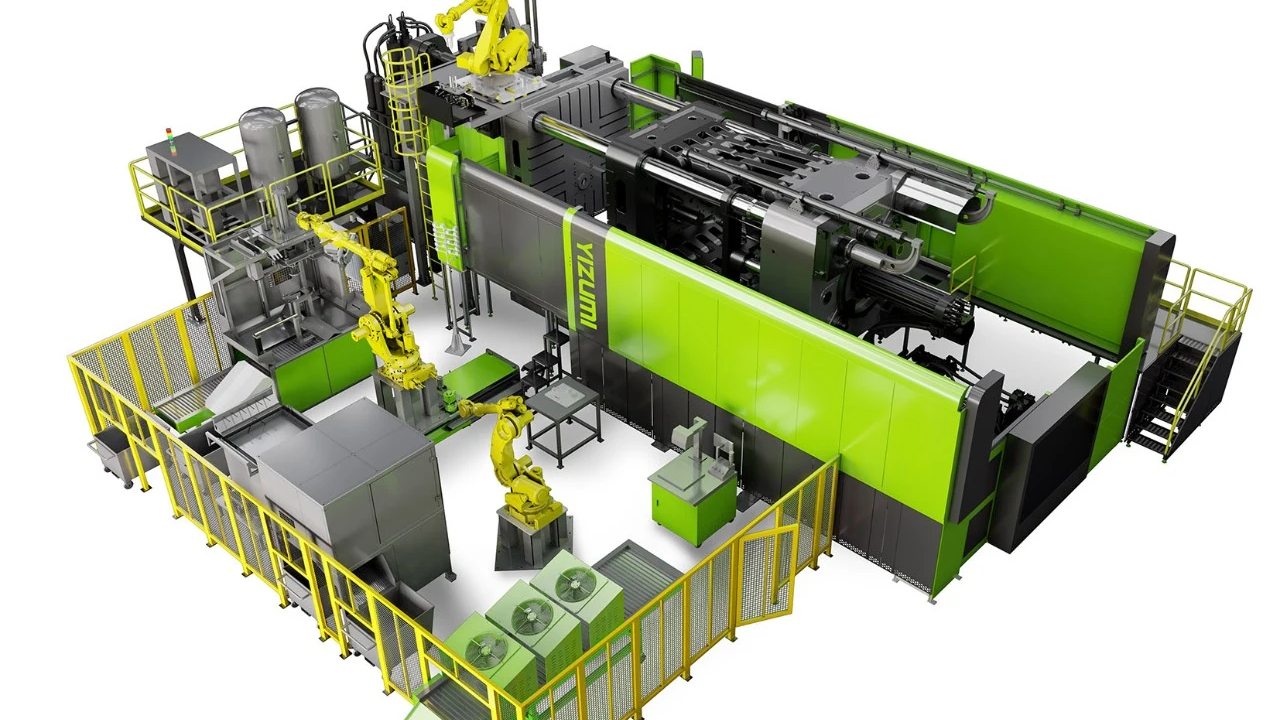

To this end, Aurora has introduced YIZUMI C series multi-component and A5 series injection molding machines. The clamping unit of multi-component machine is reliable and stable, featuring accurate turntable positioning. The BFC (balanced force clamping) technology can adjust the clamping force transmission direction so that the force is applied to the mold more evenly and injection molding is more stable. The DCPC (digital closed-loop positioning control) technology ensures the accuracy and high repeatability of turntable positioning.

YIZUMI C series high-end multi-component injection molding machine

Mr. Zhang Wei added, "So far, YIZUMI machines can fit the production requirements well. The molding of parts with high-gloss appearance is free of defects like black spots, flow marks, bubbles, and silver streak. The dimensional accuracy of the products is 0.02mm, and the qualified rate of products is above 98%, ensuring the quality of our products."

Moreover, to meet the increasing demand for customization and personalization of consumer electronics, Aurora has conducted thorough research on consumers' lifestyles and changes in needs, focusing on the exploration of customer experience and to bring users pleasant life experiences.

Empowering advanced manufacturing with digitalization

AURORA has achieved major highlights of "personality + intelligence" on Bluetooth headsets and speakers and earns a significant reputation in the industry. Simultaneously, it has been developing and expanding with the spirit of "honesty and trustworthiness, proactive progress, pursuit of innovation and excellence".

However, AURORA still faces a number of pain points and obstacles that hinder its future development in its digital and intelligent transformation. For example, the production switch of orders from a single category production of earphones to multi-category, complex production of Bluetooth speakers and household appliances, etc. Those factors stop the forming of effective production management, like the extension of production lines and the increase in the types of purchased materials, are the top priority for Mr. Zhang Wei.

For this, he explained: "Today's market competition is fierce, customers have too many choices, and cross-category competition is getting sharper. The profit margins will be further squeezed if we don't reform. Especially since the manufacturing industry was transformed by the advent of the 'Industry 4.0', manufacturers have focused on the capabilities to control costs. Therefore, empowering advanced manufacturing with digitalization is the key to achieve transformation of quality, efficiency and motivation."

To address all kinds of problems in the digital transformation at source, AURORA finally decided to further cooperate with YIZUMI after a detailed research. Our technical team researched in depth at AURORA workshops and provided a turnkey solution for every essential and process in the production, helping AURORA better realize its digitalization.

Intelligent manufacturing boosts AURORA's transformation and upgrade

In October, 2022, YIZUMI whole-process digital management project has been officially operated by AURORA to collect, manage, analyze and trace back data of raw materials, products, energy consumption, production and so on, making the production process more transparent and better improving the factory management.

With the help of YIZUMI Manufactory Execution System (Yi MES), AURORA realizes production visualization, monitors equipment information, and improves delivery rate. In addition, users can directly monitor the production situation through the embedded system in the cloud platform. ERP, CRM and other production management systems can be tightly integrated into the platform simultaneously to connect the production with the five major elements like man, machine, material, method and environment, helping AURORA achieve digital production management.

And now, a series of information such as real-time order status, inspection status, production schedule, and the percent of pass is accessible conveniently via phone and computer, and the data accuracy reaches 99%. The systematization and visualization of the production, in addition to real-time monitoring of process progress, enable production efficiency to reach 90%. Furthermore, breaking down the isolated islands of information and handling abnormal production timely raise the on-time delivery rate of orders to 93%. With the further development of informatization, and the in-depth integration of the automation and informatization, AURORA moves a further step toward becoming an industry benchmark.

In other words, YIZUMI has helped Aurora realize digital transformation and provided a strong support to its industry extension strategy.

In the future, YIZUMI will keep providing better products and services by integrating our technology and business processes. We will also develop more comprehensive and secure innovative products and solutions to build multi-level and multi-field applications and promote the intelligentization of equipment and products. Furthermore, we will continue to improve corporate production efficiency and economic benefits, assisting customers in industrial upgrading and gaining higher value with more competitive advantages.

Please do not hesitate to contact us for more details on Yi MES.

Email: huangmin@yizumi.com

*The data above were acquired by testing in the factory, only for your reference. As to the specific data, please refer to the actual equipment.