YIZUMI at Fakuma Germany 2023

On 17th October, local time, Fakuma 2023 is grandly opened at Messe Friedrichshafen in Germany. This five-day industry feast has attracted almost 1,500 exhibitors.

At stand B5-5405, YIZUMI Germany exhibits two electric injection molding machines, the FF200M and FF90, which produce disposable sterile syringe caps and plastic skeletons for the motor on site. We also demonstrates how to improve plastic processing production efficiency through energy efficiency, intelligence, and sustainable development, helping customers in different fields and industries to produce products with lower energy consumption.

There are many varieties of medical products, each with its own set of raw materials, structure, and quality standards. Based on the process features of different medical products and injection molding regulations in medical cleanrooms, YIZUMI has developed a range of injection molding machines special for the medical industry. The FF200M special medical machine is equipped with a 128-cavity syringe cap mold, which has high production efficiency and product quality, and is ideal for cleanroom production.

Demo production of disposable sterile syringe caps by FF200M electric injection molding machine special for medical industry

Product: Disposable sterile syringe cap

Material: PP

Cavity: 128

Weight: 0.8g/pc

Size: Φ8*42mm

Cycle time: 8+/-1s

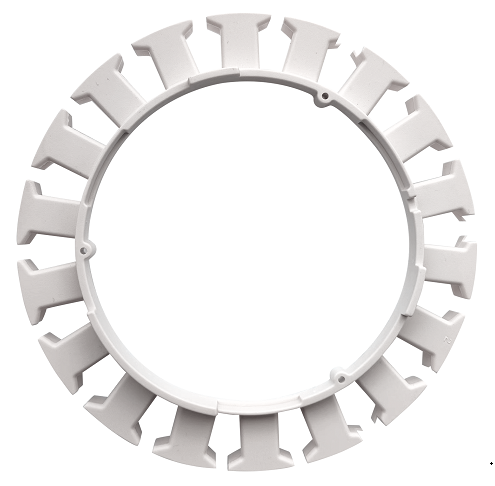

A motor's plastic skeleton is a precision, thin-walled product with strict size and quality requirements. Defective conditions such as short-shot, stress deformation, and flashes are not allowed. The performance advantages of the FF90 electric injection molding machine include stability, precision, high efficiency, energy saving, intelligence, and automation, which can better meet the molding production of precise thin-walled products.

Demo production of plastic skeletons for the motor by FF90 electric injection molding machine

Product: Plastic skeletons for the motor

Cavity: 4

Material: PBT

Color: Original color

Weight: 5g

Cycle time: 15s

Germany is not just an important trade partner to China, but also the bellwether of global industrial development. YIZUMI strives to be a world-class molding equipment solution provider in the global market. And the European market is a key strategic market for YIZUMI to access to global high-end market and customer groups.

For the strategy of globalization, YIZUMI launched an R&D center in Aachen, Germany at the end of 2017. Because Germany is the source of many global world-class equipment companies, our Aachen R&D Center acts as the innovation engine that drives the upgrading of our technologies and products.

Furthermore, to better meet the demands of local customers for equipment performance, quality, and services, YIZUMI established the Lippstadt Technical Center in Germany, which mainly offers sales and services. Demand from the mid- and high-end markets has gradually risen during the operation. It encourages YIZUMI to innovate and accelerates the process of connection with the German market and technologies.

In the past two years, the fastest growing overseas markets of YIZUMI not only included developing countries, but also developed European countries like Germany and Italy, which signifies that the comprehensive competitiveness of our products is improving rapidly. We will accelerate the development of new technologies and the establishment of technical service centers and subsidiaries in major overseas markets and regions to better serve global customers in the future.

*The data above were acquired by testing in the factory, only for your reference. As to the specific data, please refer to the actual equipment.