The solution of YIZUMI FoamPro contributes to Audi e-tron

Abstract:

The solution of YIZUMI FoamPro contributes to Audi e-tron

In Q2 2022, auto exhibitions in China gradually return to normal. The Chongqing International Auto Exhibition, which was held from 25th June to 3rd July, had gathered more than 110 mainstream brands worldwide, while new energy vehicles were definitely in the spotlight. There were more than 300 models of more than 40 NEV car brands on the spot. Among them, FAW-Audi exhibited a domestic PEV model named e-tron. The car's interior was very impressive - precise processing technology and high-quality materials with excellent tactility, it was really cool.

Audi e-tron

Audi e-tron appeared at Chongqing International Auto Exhibition

The new generation of Audi e-tron adopts a light-weighting design for an extended driving range. In this regard, YIZUMI FoamPro Microcellular Foaming Injection Molding Solution also plays a vital role. The Audi e-tron center console frame produced by Changchun Huatao Automotive Plastic Trims CO., Ltd. (Hereinafter referred to as Changchun Huatao) has achieved significant weight reduction without warpage through YIZUMI FoamPro technology, which ensures smooth mass production.

Founded in 2002, part of Chengdu Space Mould & Plastic CO., Ltd., Changchun Huatao is an automotive part company specializing in automotive plastic interior and exterior trim, EPP foaming part, molded part, and plastic part of the engine. Changchun Huatao was awarded several titles such as Quality Excellence Award, Innovation Excellence Award, Excellence in Localization Award, and Excellence in Cost Control Award by FAW-Volkswagen as its tier-one supplier.

FAW-Volkswagen and Changchun Huatao have determined to adopt FoamPro technology as early as the pre-research stage of Audi e-tron Center Console Frame since this product has a complex structure and large dimension. FoamPro technology can reduce the part’s weight as well as warpage.

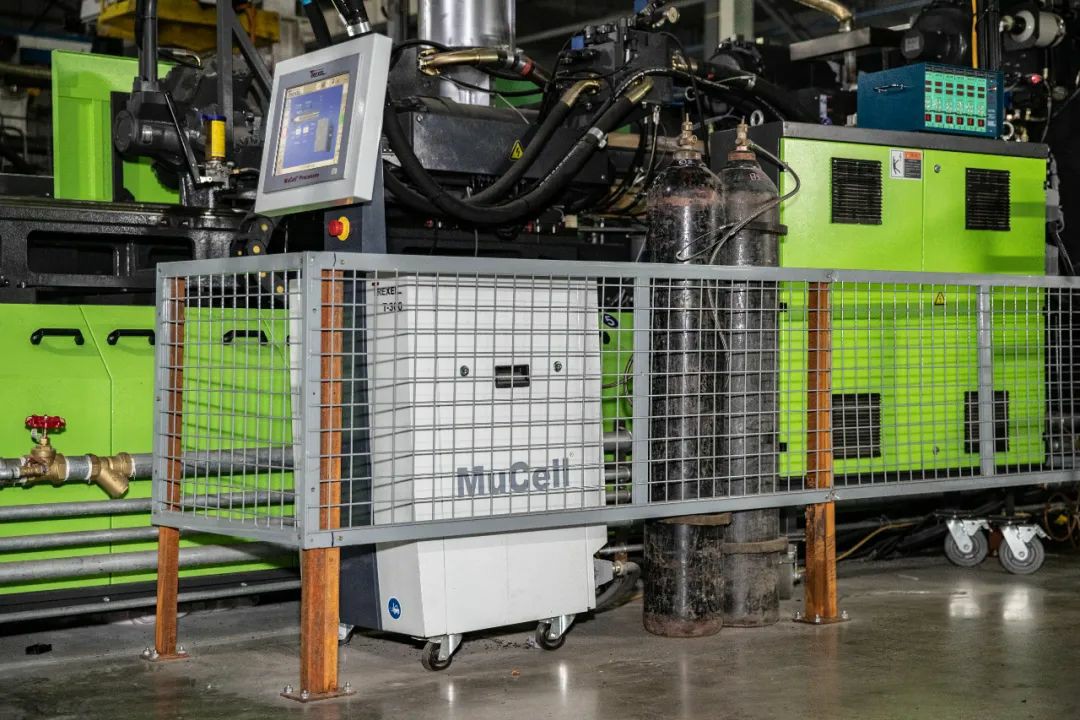

YIZUMI provided a complete FoamPro Microcellular Foaming Injection Molding Solution to meet customer’s needs. In addition to two-platen injection molding machine UN900D1, SmartClamp system, Microcellular foaming equipment, the whole solution includes a package of services such as CAE simulation analysis, mold design suggestion at the early stage, and process debugging and training after putting into operation.

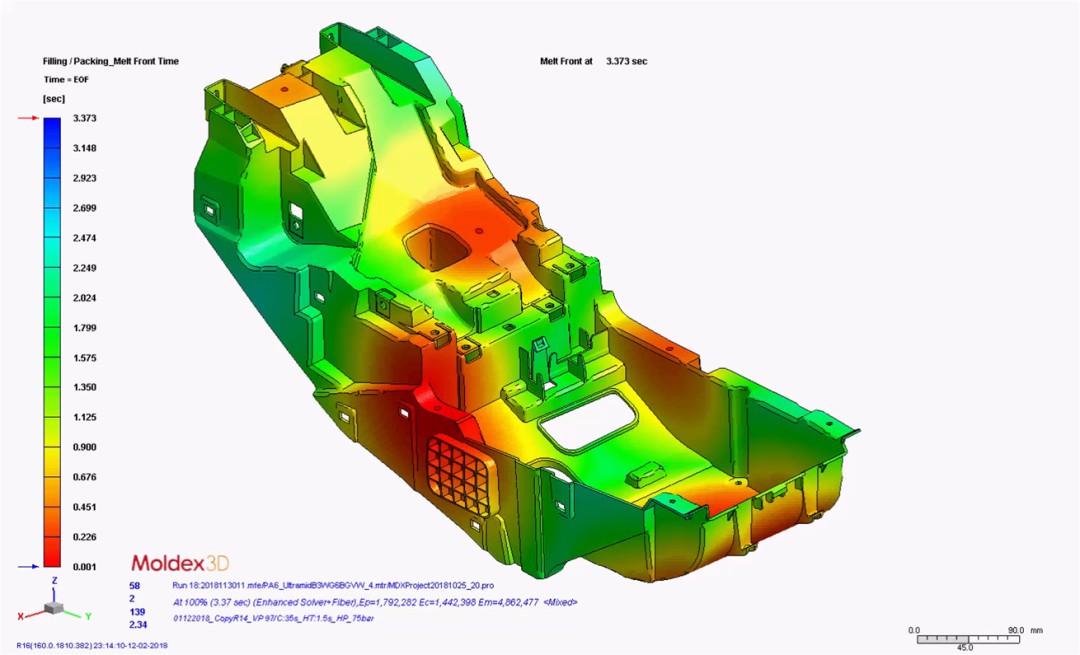

YIZUMI CAE simulation analysis assisted Changchun Huatao in mold design optimization based on certain product structure, providing suggestions about runner design, sprue, gate position, and offering material filling curve, predicting the size and distribution density of cells , etc. Otherwise, through CAE simulation analysis for deformation trend prediction, customers can take some compensation measures to correct the part warpage, which easily happens due to the complex product structure as well as filling materials of higher fiber.

After communication and optimization, YIZUMI has provided customers 8 CAE simulation analysis reports, analyzing runner design, product weight reduction, the deformation trend, and molding defects to decrease the development risk.

After the delivery, YIZUMI’s after-sales service team promptly responded to customers’ requests and assisted customers in equipment commissioning and mold trial. The qualified samples produced by the machine have passed the inspection by the OEMs. Glory Chen, Manager of YIZUMI New Material and Process Test Center, said: “The Audi e-tron center console frame is made up of nylon and glass fiber, and has many ribs. Fiber orientation and shrink may result in part warpage and an unstable dimension. For this reason, Microcellular Foaming is able to reduce part warpage as well as the weight, while saving raw materials.”

In November 2020, the e-tron center console frames were successfully put into mass production in Changchun Huatao. And its production effect was appreciated by the customers. Wang Huansen, General Manager of Changchun Huatao, explained: “The newly developed Audi e-tron center console frame was Audi’s first try in physical Microcellular Foaming in China. Meanwhile, it is also the first time we use the newly developed 900T machine of YIZUMI to produce the microcellular foaming product. The machine meets our expectations with stable performance, good production consistency, and a significant light-weighting effect. YIZUMI service team paid great attention to the project, offering timely services, and thoughtful follow-up technical support to ensure the smooth development of the project.”

All this time, YIZUMI has continued to support our customers in developing and testing new products and new processes, and dedicated to providing with cost-effective turnkey solution.

Disclaimer:Some pictures on this webpage originated from the internet and are for display purpose only. All rights reserved by the authors. Should this violate your rights, kindly advise us and we shall delete them instantly.