Yizumi will Show Cutting-edge Machines at Chinaplas 2015

Abstract:

Yizumi will Show Cutting-edge Machines at Chinaplas 2015

Yizumi is committed to facilitating Chinese machinery technology keeping pace with the world, developing and manufacturing cutting-edge products for customers who have needs of corporate upgrades to choose from and creating better investment return and experience for global customers. Yizumi is to show four industry-leading injection molding machines at the upcoming Chinaplas 2015 and gets prepared for cooperation with customers around the world to seek further development together.

Machines to be shown are DP series two-platen injection molding machine (UN1000DP), FE series all-electric injection molding machine (FE120S), A5 series universal injection molding machine (UN200A5) and PAC series high-speed injection molding machine for thin-wall packaging (PAC350).

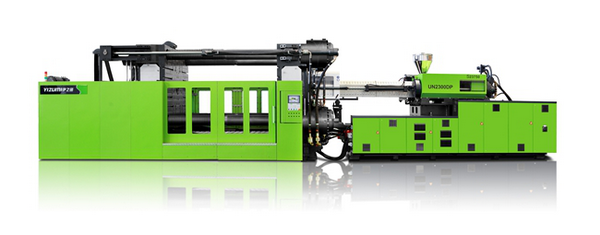

1. Two-platen injection molding machine (UN1000DP), benchmarked against German technology

Specially designed for automotive and other deep-cavity products, Yizumi two-platen injection molding machine takes German technology as a benchmark and obtains five national patents. The machine will produce car headlight covers at the exhibition to demonstrate its high precision.

lHighly-efficient: diagonally-located high-speed cylinders, extremely short stroke for clamping pressure build-up, differential pressure relief oil circuit, fast clamping, dry cycle time of 6 seconds, greatly shortened molding cycle and improved production efficiency.

lPrecise: high-rigidity platens and high-precision control of platen parallelism, movable platen controlled by high-speed proportional valve, slight friction of mold opening and closing, more precise control of the mold opening and closing and the nut-type brake mechanism ensuring extremely high precision machine movements.

lEnergy-saving: A series of servo motor-driven systems whose power range from 80 to 500kW, with flow and pressure under closed-loop control. Friction-free tie bars and linear guide rail of injection unit also make the machine as energy saving as an all-electric injection molding machine.

lSafe: User-friendly auxiliary equipment interface and design conforming to multiple safety standards (GB, CE, and UL etc.) ensure a safer and more reliable production process.

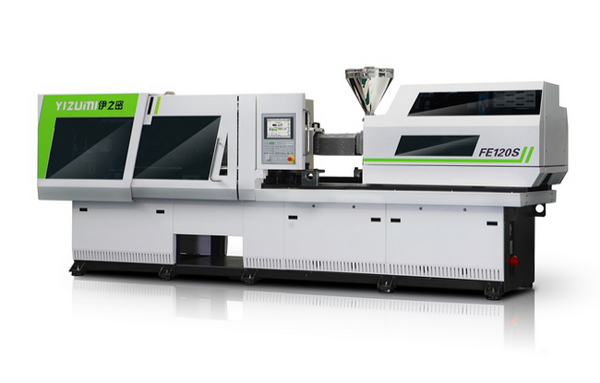

2. All-electric injection molding machine (FE120S), benchmarked against Japanese technology

Yizumi’s first self-developed all-electric injection molding machine is based on the characteristics of European and Japanese counterparts and features “speedy, precise, silent, energy-saving and stable”. The product is widely applicable to technically-demanding plastic processing industries, especially photoelectric equipment, medical equipment, automotive accessories, electronic and electric appliances and food packaging. The machine is widely recognized by customers since launched and proved as a substitute for imported counterparts.

l12-inch LCD screen and high value-added software make the operating system more user-friendly. Three-minute mastery of the machine operation greatly enhances efficiency.

lHighly-efficient precise injection molding, dry cycle time ≤ 1 second, the shortest injection molding cycle ≤ 3 seconds, product repeatability ≤0.03mm, energy saving of 75%.

lConsistency and progress in R&D technology result in a simpler and smoother injection molding process, and provide better investment return and experience for customers.

lThe machine conforms to China’s GB22530 national standard.

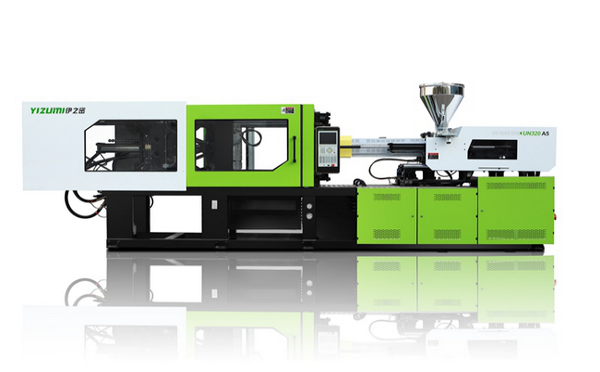

3. A5 series universal injection molding machine (UN200A5)

As a servo injection molding machine targeting mid-and high-end customers who have needs for upgrading universal injection molding machines, A5 series features wide range of application, reliable quality and high price-performance ratio. End markets of A5 series include 3C products, electric appliances, auto parts, medical, packaging, logistics, building materials and commodities. The machine will demonstrate producing 9.7-inch 1 mm thick IPAD protective covers on a one-cavity mold at our booth.

lStronger processing capacity thanks to the upgrade of configuration and technical specifications

lUniform-stress molding technology and precise linear injection technology achieve stability of the machine operation

lConsistent product quality due to lean-oriented operating procedures

lMore energy-saving with the use of the 3rd generation servo system, optimized hydraulic system and low-friction moving parts

l10%-15% higher efficiency than conventional injection molding machines

lUser-friendly HMI

4. High-speed injection molding machine for thin wall packaging

This latest machine is specified to thin-walled packaging applications such as thin-walled containers, bottle caps and medical devices, featuring high efficiency, stability, energy saving and cleanliness. Yizumi is committed to raising the input-output ratio, providing systematic solutions that include mold and auxiliary equipment and promoting the transition from extensive development to intensive development of the industry.

lHigh-rigidity clamping unit greatly minimizes deformation of platens and makes the machine perfectly qualified for molding thin-walled parts with strict requirements. Stress is well distributed to the mold which gets better protection.

lOptimized toggles make mold opening and closing smoother.

lThe single-cylinder injection unit features compact structure and little inertia, notably increases the injection precision and ensures perfect molding of high-precision products.

lHigh-strength machine base increases machine’s stability.

lVariable configuration of the power system is at customer’s choice: variable displacement pump, fixed displacement pump and accumulator, etc.