YIZUMI Speeds up Die Casting Technology Development under Global Pandemic Hit

Abstract:

YIZUMI Speeds up Die Casting Technology Development under Global Pandemic Hit

In 2020, the global spread of the COVID-19 pandemic has sent the world economy into severe recession, automobile, cellphone, aerospace, and other industries have been suffering heavy losses. There is still great uncertainty in the market. Facing difficulties, how does YIZUMI move forward in this adversity?

Stefan Fritsche, YIZUMI CSO for die casting &metal forming said YIZUMI will use the current, difficult times to prepare well for the next growth period, “Our aspiration at YIZUMI die casting will not be changed by the current situation. We do focus on providing our customers worldwide with die casting solutions of high productivity at fair prices allowing our customers to achieve the best return on investment.”

Stefan Fritsche, YIZUMI CSO for die casting & metal formig

European Die Casting Industry revenue is expected to drop considerably

The automotive industry is one of the most important customers for the die casting industry worldwide. Therefore, the condition of the automotive industry is highly relevant to gauge the health of the die casting industry in these challenging times. Based on various forecast we have to expect that the global automotive sales volume for 2020 will have a large year-on –year decline, among which the decline of the US and European markets will be greater than that of the Chinese market. Therefore, the order intake of die casting machine producers worldwide is certainly significantly reduced. Mr. Fritsche said: “My discussions with managers in the European die casting industry confirm above situation as these managers do expect their revenue in 2020 will greatly decrease than 2019.”

According to Fritsche’s assumption, the global die casting machine order will dramatically decrease, and the current 2020 order book of die casting machine manufacturers in Europe and North America will sharply fall compared to the previous year.

Fritsche said “If markets pick-up towards the end of 2020 the order intake situation might improve, however there is still great uncertainty to establish any meaningful forecast at this time.” It is encouraging to see that China seems to be well on track to recovery of the economy. In June, the automotive sales year on year grew by about 11.6% based on preliminary data released by China Association of Automobile Manufacturers (CAAM). Europe is in the middle of easing the lockdown, automotive manufacturers have been back to resuming production. Fritsche said “I think the first signs are positive. If a recovery sets in, confidence will return and that would certainly also increase demand.”

Preparing for the Next Growth Period

Although the die casting industry has slowed down because of the pandemic, in China industries such as 5G, lightweight and new energy vehicles are growing and investments in these areas are realized.

As a die casting machine- and automation solution provider, YIZUMI is at this time focusing on preparing for the next growth period. YIZUMI`s goal is to aggressively improve its highly cost-efficient die casting solutions further to provide our customers with highest OEE`s at fair investment costs.

An example is the new YIZUMI D-Speed 350 High Speed Die-Casting machine introduced this year which is focusing to provide highest production efficiencies for ultra-thin-walled aluminum alloy die castings as used for 5G mobile phone mid-boards demanding highest dimensional quality requirements.

In addition, YIZUMI invested heavily in upgrading its manufacturing plant for heavy-duty large die casting machines to cope with the strong growth in 5G base station component manufacturing. This investment was completed and doubles the manufacturing capacity of large die casting machines.

Fritsche explained that “China is the leader in 5G technology. This ensures that there is still growth in the market for die casting machines above 3000t of locking force. So, there are still great opportunities for our domestic team in this growing market segment.”

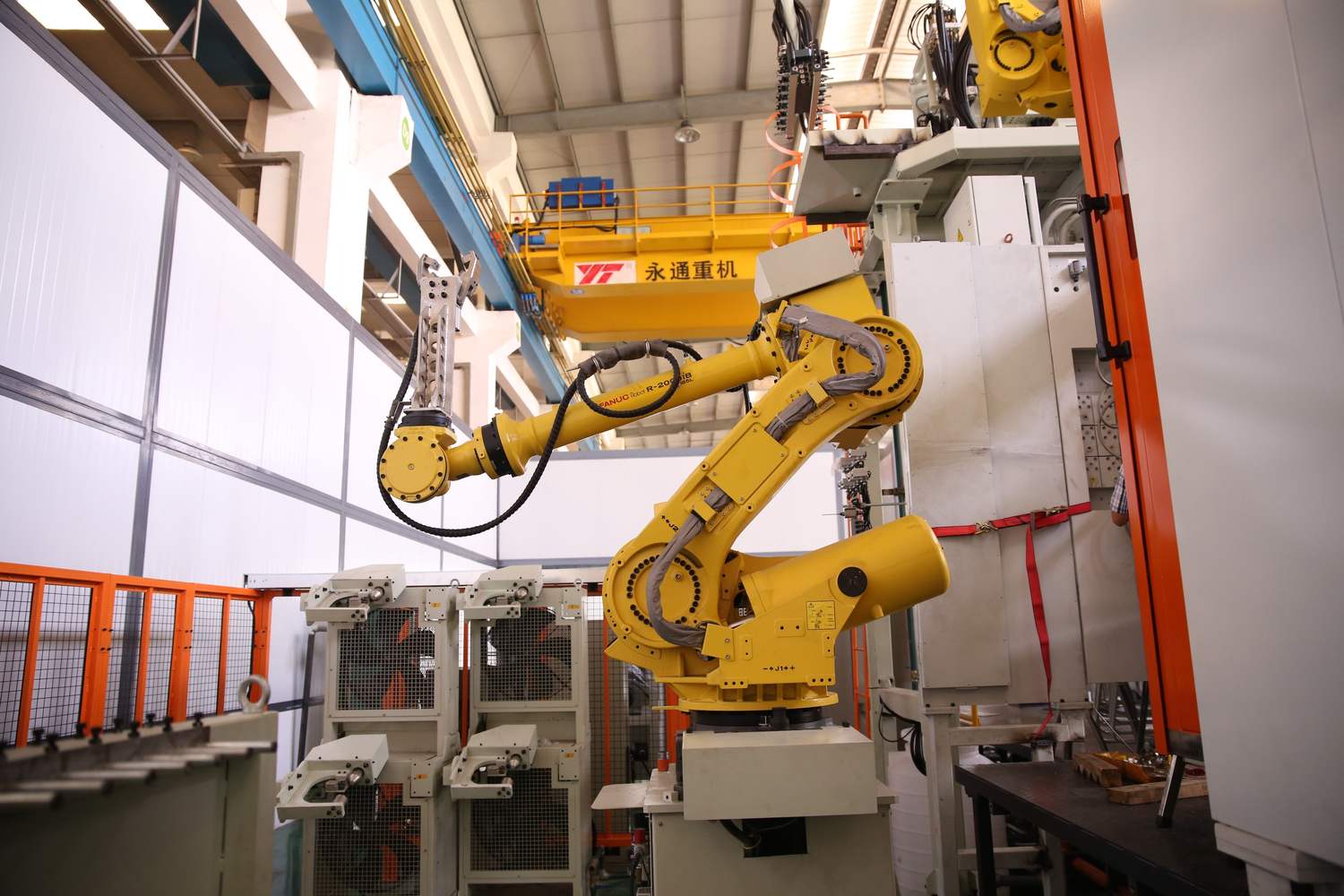

Speed up Die Casting Technology Development

In order to provide our customers with ever better solutions and technology, YIZUMI invested in building a die casting Product and Process Application Center (PPAC). This technology center featuring a fully automatic 3000t die casting cell allows the YIZUMI technology team to develop crucial die casting process knowhow which will result in improving our die casting equipment design and its technological performance. The PPAC also offers a great platform to do casting trials for our customers as well as providing die sampling. Our mutually beneficial cooperation with Guangzhou Die & Mold generates additional knowhow for YIZUMI in the area of tooling and die design. Future projects include customer training courses in die casting process optimizations as well as training in tooling design.

The PPAC facilitates a “technology learning process” assisting our engineers to further understand die casting technology from the customers’ perspective. This extends our knowledge base to further optimize the design of our die casting equipment and automation solutions for our customers.

“It is our aim to helping customers to achieve a better Overall Equipment Effectiveness (OEE) on their use of our equipment in order to be highly competitive in the market” Fritsche said.

Our PPAC has been received well by our customer base and has led to interesting discussions about future technology projects.

As for the tech center`s future operation, Fritsche firmly expressed that: “With our goal to become a leader in our field we do need to understand how to further develop our products, services and solutions on our own. So, the goal is to establish a strong skill set in our organization. To execute well we do need to start however in training our teams to a high knowhow level. Only with highly trained specialists will we be able to provide crucial support to our customers making a difference between our competitors and us.”