Yizumi Shows Prominent Technical Strengths at Chinaplas 2015

Abstract:

Yizumi Shows Prominent Technical Strengths at Chinaplas 2015

As one of the largest equipment manufacturers in China, Yizumi showed four high-quality injection molding machines at Chinaplas 2015 which was a showcase for technical innovation ability of a company, and they got the spotlight at the four-day event.

A5 Series Universal Servo Injection Molding Machine

Upgrade in Both Software and Hardware

Chinaplas 2015 was where A5 series was shown to the public for the first time. UN200A5 from A5 series produced 1 mm-thick iPad Air 2 protective covers at the booth to demonstrate its excellent performance. Unlike ordinary universal injection molding machines, A5 series targets mid-and high-end customers who have needs for upgrading their equipment. Based on the technological essence of A2 series, A5 series is the application of uniform-stress molding technology and precise linear injection technology and equipped with the 3rd generation servo system, optimized hydraulic system and low-friction moving parts. All these features ensure higher precision, reliability, stability, as well as a 10%-15% increase in efficiency.

In addition to the hardware upgrade, software of A5 series also becomes more intelligent. Customer can get access to ERP via Wi-Fi to carry out production scheduling, production capacity and power consumption analysis of injection molding machine. A5 series will be Yizumi’s main product in the next 3-5 years to meet customer needs of transformation and upgrade.

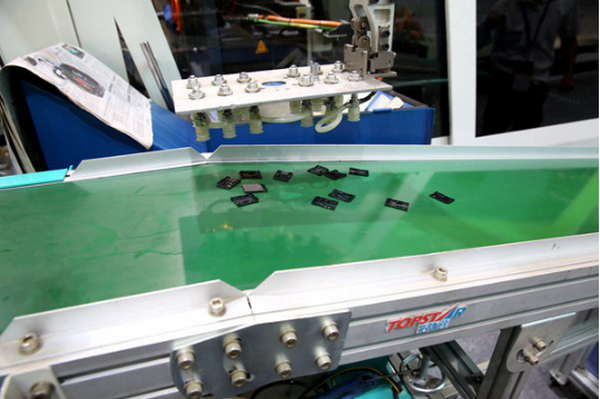

PAC Series High-speed Injection Molding Machine for Packaging

High Speed and High Performance

FE Series All-electric Injection Molding Machine

Master the Operation of Machine in Three Minutes

Based on the characteristics of European and Japanese counterparts, FE series is benchmarked against Japanese technology and more user-friendly to Chinese customers than the Japanese counterparts. The machine is equipped with a 12-inch LCD screen and high value-added software. It takes the operator only three minutes to master how to operate the machine.

FE series also has competitive performance in high-efficiency precision injection molding: dry cycle time ≤ 1 second, the shortest injection molding cycle ≤ 3 seconds, product repeatability ≤0.03mm and energy savings of 75%.

DP Series Two-platen Injection Molding Machine

Benchmarked Against German Technology

Specially designed for automotive and other deep-cavity products, DP series takes German technology as a benchmark and obtains five national patents. The machine produced car headlight covers at the booth to show its outstanding precision and stability, with dry cycle time of 6 seconds that greatly shortened molding cycle and improved production efficiency.

Customer Comments

"Our company mainly produces interior parts of home appliances. We are old customer of Yizumi and we’ve been using Yizumi’s SK series and SM series injection molding machines since 2012.At this trade show, we are interested in PAC series as we intend to purchase such kind of specific injection molding machines for mass production of disposal fast food containers. What impressed us first was the appearance of PAC. Then we saw the machine produce lids of fast food containers with eight-cavity molds at the booth. The machine completely met our requirements in speed, stability and automation.” said Zhang Xiaoqing from Laite Plastic Products Co., Ltd.