Yizumi presents SPACE A robotic flexible additive manufacturing system at formnext 2018

Abstract:

Yizumi presents SPACE A robotic flexible additive manufacturing system at formnext 2018

On October 13th, Formnext 2018, the world’s top exhibition on additive manufacturing, opened in Frankfurt Germany. It is the first time that Yizumi has participated in the event where Yizumi’s German subsidiary presents its new product: the SPACE A robotic flexible additive manufacturing system, which attracted a lot of visitors’ attention. This is also the second time that SPACE A has landed in Europe's top technology exhibition after Fakuma 2018 held in October.

Formnext is an international exhibition and conference on the next generation of manufacturing technologies. The annual event is an entire platform for companies from the world of additive manufacturing. Here, a veritable who’s-who from the realms of design and product development, industrial tooling, production solutions, quality management, and measurement technology comes together with leading providers in basic materials and component construction.

21,492 well-informed visitors - 54 % from Germany and 46 % from other countries were present at Formnext 2017. This year's event once again highlights the latest trends and issues in additive manufacturing. It also explores clever ways in which AM can be integrated into process chains in industrial production. In addition, top international speakers and other experts will be on hand to engage conference attendees in in-depth discussions at the highest technical level. There are 550 exhibiting companies at this year’s event.

Additive manufacturing refers to the technology of manufacturing solid parts by gradually adding materials. Compared with the traditional material removal-cutting technology, it is a “bottom-up” manufacturing method.

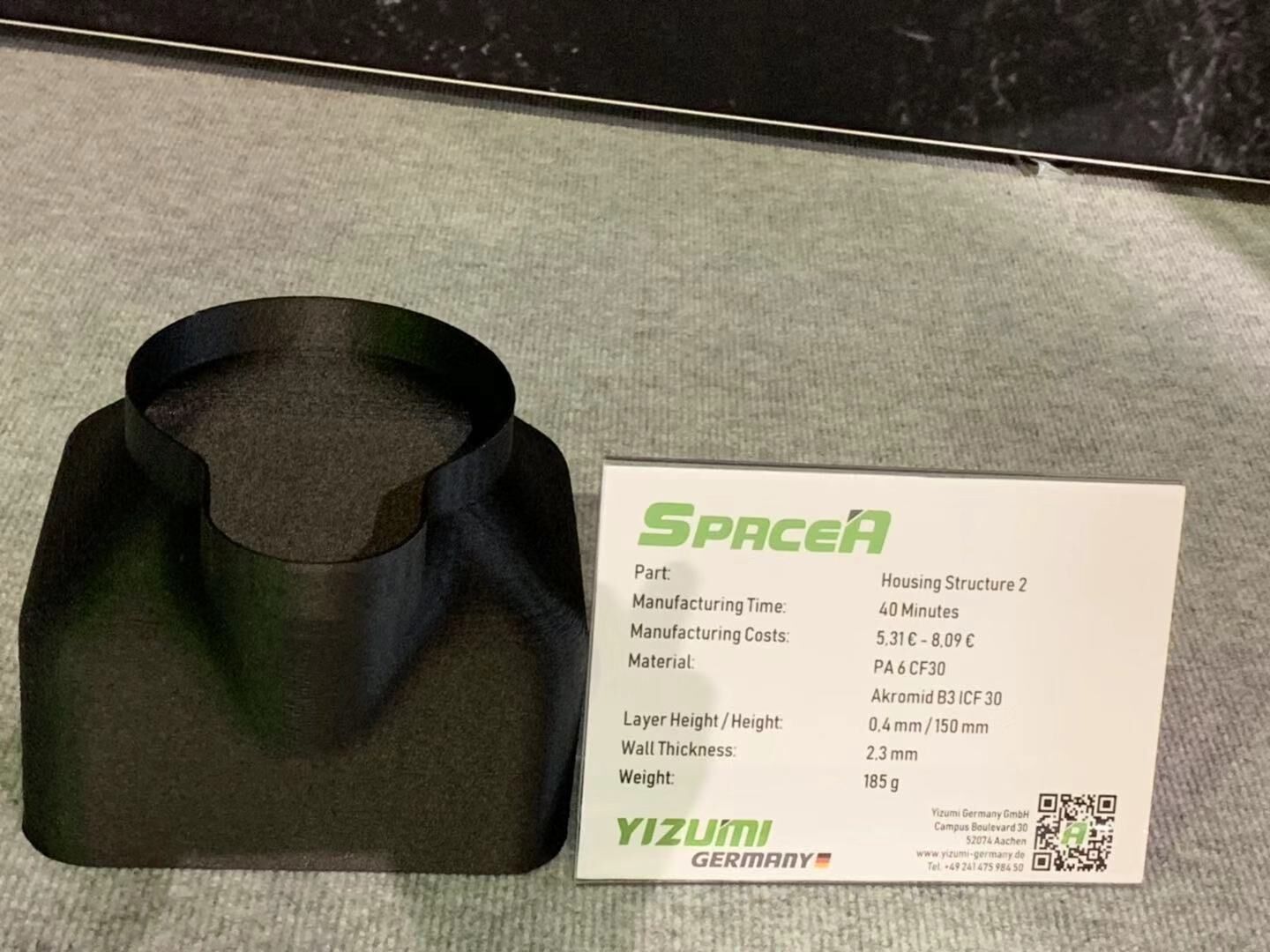

Yizumi SPACE A robotic flexible additive manufacturing system is a kind of equipment that can integrate different manufacturing processes. This machine can be used in combination with additive manufacturing processes (also known as 3D printing) or other processes such as inserts and subtractive manufacturing. At the booth Yizumi SPACE A printed structural parts of different sizes with PA6 CF30 as the printing material, and the cycle time was not more than 40 minutes.

The parts produced by Yizumi SPACE A robotic flexible additive manufacturing system can be applied to the fields of automobiles, home appliances, construction, etc., providing cost-effective production method and achieving high-quality automated small-scale production of customized components. Through different combinations of units, Yizumi SPACE A can use other special materials such as continuous fiber reinforced materials, low melting point alloys, thermosetting and elastomeric plastics for production.

Visitors can experience the entire YIZUMI SPACE A solution from November 13-16 in hall 3.0, booth J80.