YiMES: Begin the Digital Transformation Journey

Abstract:

YiMES: Begin the Digital Transformation Journey

In today’s manufacturing industry, most enterprises have established their own standardized, process-based production methods. But the real dilemma before us is the rising costs with production efficiency approaching a “ceiling.” Traditional, optimized production methods become increasingly inadequate to fulfill the ever-rising expectations of the market.

In the face of these challenges, the transformation toward digitalization is imminent for the enterprises world-wide. YIZUMI has launched the YiMES intelligent manufacturing execution system designed specially for the small and medium-sized enterprises in the field of injection molding, die casting and rubber molding, aiming to remove data silos, place the entire production process under control, and provide customers with digital factory solutions.

Full-process, Multi-level Digital Factory Solutions

What is the need for digital transformation in molding and casting enterprises?

Take one of Yizumi’s customers as an example, after years of development, they now own more than 40 machines. The company has strict quality control requirements and strives for production management excellence. Their products are well recognized by international buyers. However, with the continuous growth of its business, bottlenecks in production management start to surface.

The difficulties on scheduling, capacity statistics, efficiency statistics and other analysis requirements have increased significantly. It is challenging for the management to further improve operational productivity. In the words of Jianwen Niu, Director of the Intelligent Interconnection Department of YIZUMI: “enterprises need new management tools and methods that allow to further enable the organization through information technology and data-based measures”.

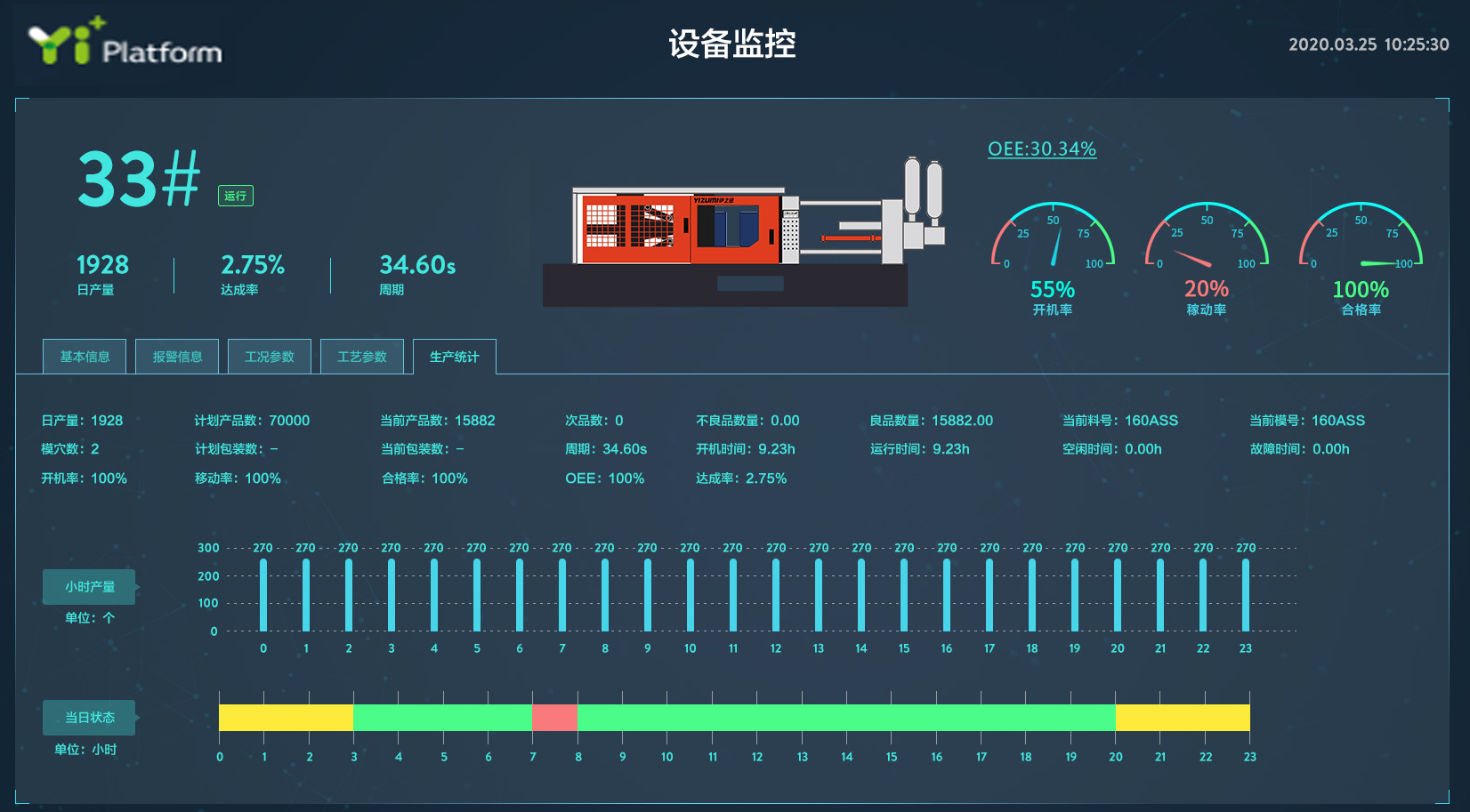

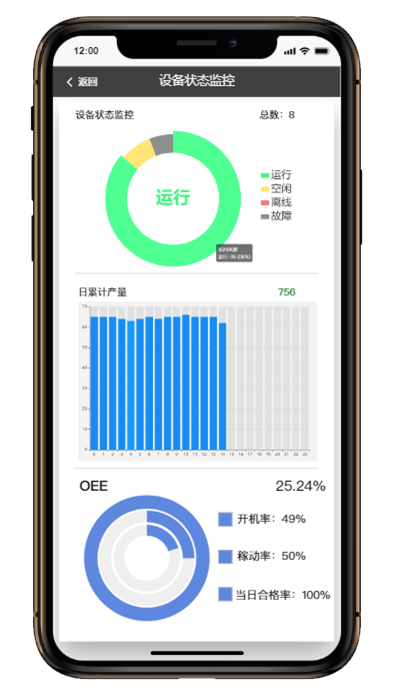

To tackle problems encountered by customers in the development of their organizational effectiveness, YIZUMI’s YiMES intelligent manufacturing execution system integrates IoT, Cloud, Big Data, AI, and other new generation ICT technologies to various professional tools, including order management, production management, quality management, process management, production monitoring, energy consumption management, and mold management that fulfills the needs of small to medium sized enterprises in their digital and intelligent development.

By offering a full range of services, including PO fulfillment, pre-production preparation, output monitoring, defect detection, finished goods warehousing, and other processes, YiMES system helps you to achieve a high level of production control throughout the entire process. It enables you to have standards before production, control during production, and product tracing after production to prevent and remove defect products.

Upon the implementation of the YiMES intelligent manufacturing execution system in 2018, the above mentioned Yizumi customer achieved 100% product quality tracing and 100% PO progress system management after a short period of time. The efficiency of equipment increased by more than 10%.

YiMES system is developed to meet different needs of users at different levels. For instance, workshop operators can perform easy and simple operations via PC or mobile phones while production directors and supervisors are able to perform real-time monitoring over scheduling and production progress, machine status, establish efficiency statistics and analysis as well as carry out pre-production preparation for the complete value stream. At higher level, the management can manage the work floor through timely, transparent and data-based reports.

“YiMES provides customers with a full-process and multi-level professional solution for digital factory, helping customers to manage their pain points, improve quality, reduce cost, and increase productivity.” said Jianwen Niu.

Intelligent Process Management

Unlike traditional MES systems, the YIZUMI YiMES intelligent manufacturing execution system is developed based on the Yi+ platform (YIZUMI Intelligent Equipment Industry Internet Platform). It also support die casting cell integration with standardized communication protocols between die casting machine and peripherals. Cloud management of all devices further reduces customers’ costs on implementation, operation and maintenance activities.

Data collection has always been a headache for the injection molding enterprises. With a wide variety of product types and equipment brands, the amount of production parameters available is humongous. This makes data collection and analysis particularly difficult. As a platform specialized in injection- and rubber molding as well as die casting processes, YIZUMI’s Yi+ has its unique advantages. Its Yi-CMS system can pick up parameters, overlying pressures, temperature, speed, time, and position of each molding cycle. Besides its benefits in improving injection molding processes, Yi-CMS may be applied to die casting as well as rubber injection molding processes.

According to Jianwen Niu, “The data collected is comprehensive. We understand what each parameter represents,” and more importantly, how to use these data after collection. “The relationship between the process parameter of each mold opening/closing and the product yield will be the base for YiMES to optimize the process in the future.” As Niu Jianwen said, with the collection of three years worth of data on each mold opening and closing, YiMES can calculate which parameter set will achieve the best yield possible. These parameters will then be recommended to customers. It not only will help the customers to improve their production yield, but also to avoid machine downtime in case there is no machine adjustment specialist available at the site.

Launched in 2018, YIZUMI’s YiMES intelligent manufacturing execution system has significantly reduced the cost of digital transformation through its cloud-based services and created great excitement in the market. It has now been used in the fields of electrical equipment, 3C, 5G, automobile, packaging, and home appliances, providing customers with cost-effective digital plant solutions.