Wuxi LANGSHION:YIZUMI UN650MGII Thixomolding Machine Has Passed the Acceptance Test

Abstract:

Wuxi LANGSHION:YIZUMI UN650MGII Thixomolding Machine Has Passed the Acceptance Test

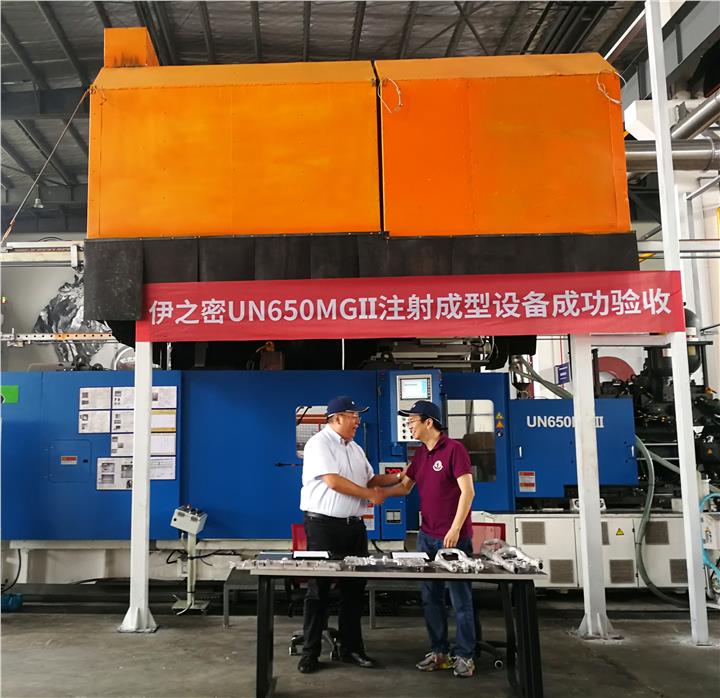

On 10th July, YIZUMI UN650MGII Thixomolding machine had successfully accepted by Wuxi LANGSHION Lightweight Technology Co., Ltd., (LANGSHION). It has been placed into mass production for bicycle front fork, dashboard rear cover and other magnesium alloy spare parts.

(Left)YIZUMI Managing Director Richard Yan (Right) LANGSHION’s founder and General Manager Mr. Chen Yang

Founded in 2013, LANGSHION is the first Chinese enterprise mainly focuses on hot forming, hydraulic forming, aluminum & magnesium die casting for automobile lightweight tools and products. Considering of long-term investment strategy in lightweight technologies solutions, LANGSHION purchased YIZUMI UN650MGII Thixomolding machine in September 2019.

Thixomolding technologies uses chipped magnesium alloy as raw material, which will be directly delivered to the machine via hopper to the barrel without application of furnace, ladler, and SF6 shielding gas. It is an environmentally friendly, safe, and effective magnesium alloy molding process.

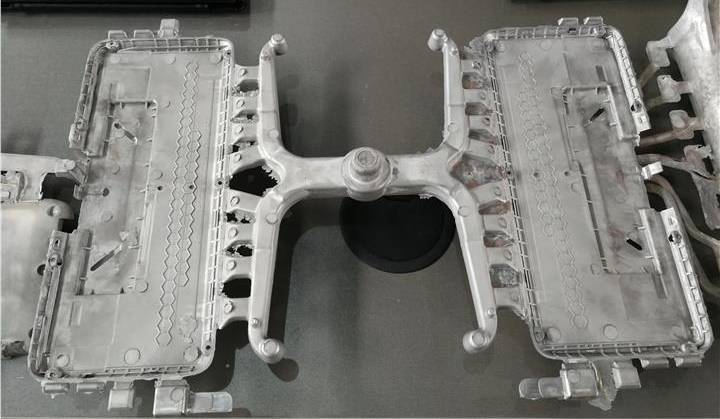

LANGSHION paid high attention to this new production process. By collaboration with end customers and YIZUMI technical team, LANGSHION carried out several testing, analysis, and solution adjustment in the aspects of materials, tooling, production cycle, equipment configuration, performances, etc., UN650MGII is officially placed into mass production in May this year, producing bicycle front fork——一 a component which demands high safety , density and gas tightness.

Sui Tiejun, Product Manager responsible for YIZUMI Thixomolding project said: “It is a very difficult-molded product.” YIZUMI UN650MGII adopts hot drop technology, screw and barrel with larger shot weight and high-power Nano-infrared heating coils to stabilize production and improvement of molding efficiency. Especially the hot drop technologies which was researched and introduced by YIZUMI Germany R&D Center could reduce and eliminate drops of temperature during Thixomolding process, which result with cost reduction.

In addition, according to LANGSHION actual production requirements, YIZUMI UN650MGII added various software functions such as display of clamping force, rapid temperature setting with parameter data recording, real-time graphic display. This provide easier and enhance user-friendly operation.

Since May, UN650MGII has arranged several magnesium alloy products into mass production. LANGSHION is satisfied with its performances. LANGSHION’s founder and General Manager Dr. Chen Yang expressed that the entire procedure from equipment installation, adjustment to smooth production is faster than they expectation. “Basically, it could perform with mass production after one or two trials on the tooling, therefore we are satisfied with YIZUMI’s equipment and also our own tooling quality as well.” Equipment’s successful operation increases LANGSHION's confidence of this new technologies & process. LANGSHION will apply this new technologies with more products to increase productivities.

|

YIZUMI Thixomolding machine is jointly developed by YIZUMI Germany R&D Center and Chinese technical team. Now we had successfully introduced models of UN650MGII & UN1250MGII, which were mainly applied in automobile, urban transportation, 3C and other fields. Customer include HETTICH in Germany, American MM, the Lightweight Foundries Technology and Project Engineering Center “GTK” which located in University of Kassel Germany, etc.